Modified starch catalyzed by compound bio-enzymes and preparation method and application thereof

A technology for compounding biological enzymes and starch, applied in textiles and papermaking, paper, non-fibrous pulp addition, etc., can solve the problems of complex process, long preparation time, poor modification effect, etc., and achieve process simplification, short reaction time and equipment. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

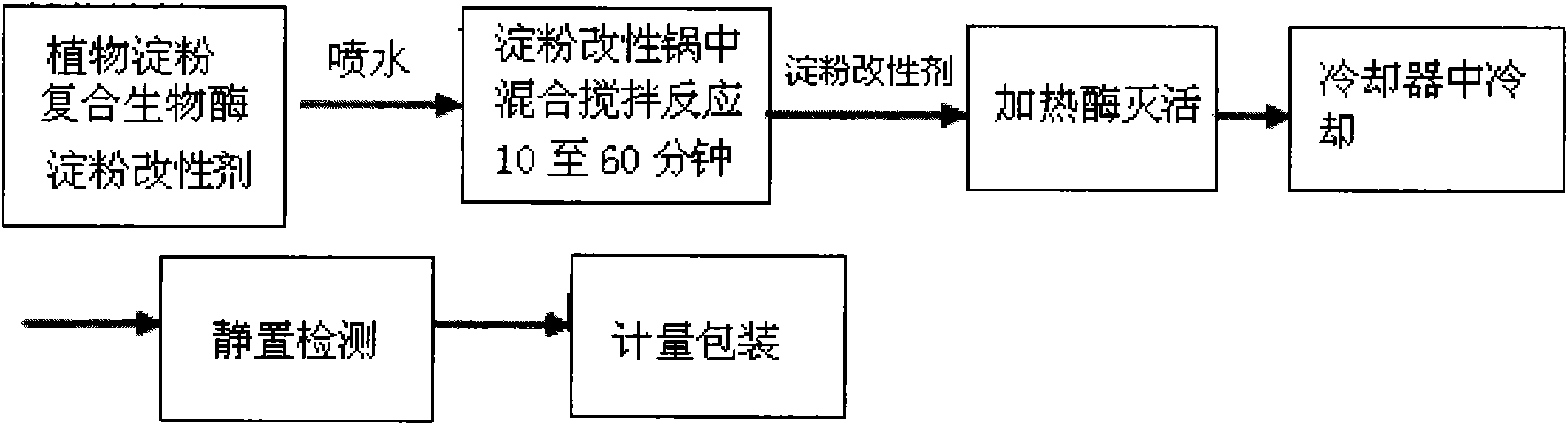

Method used

Image

Examples

Embodiment 1

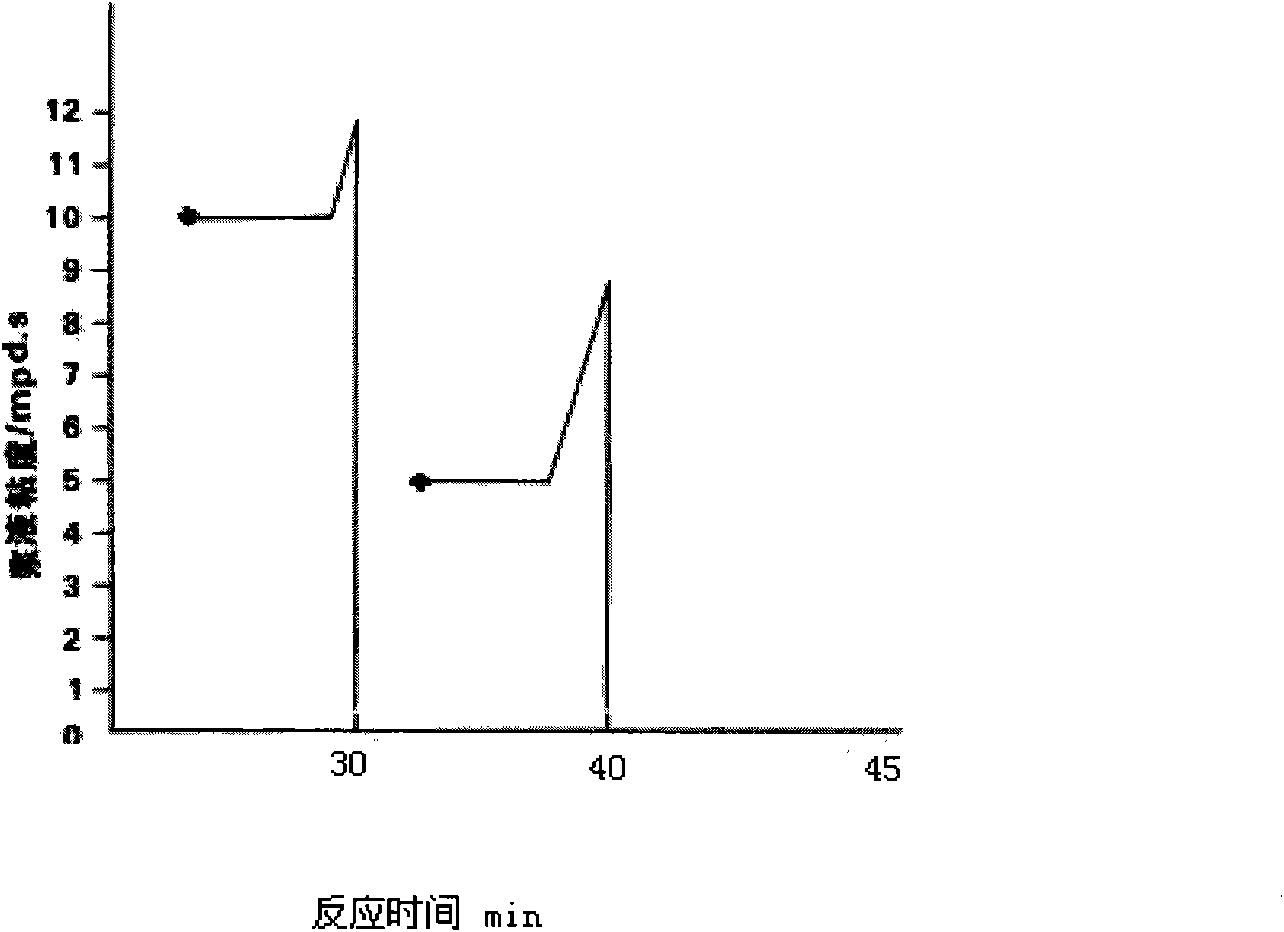

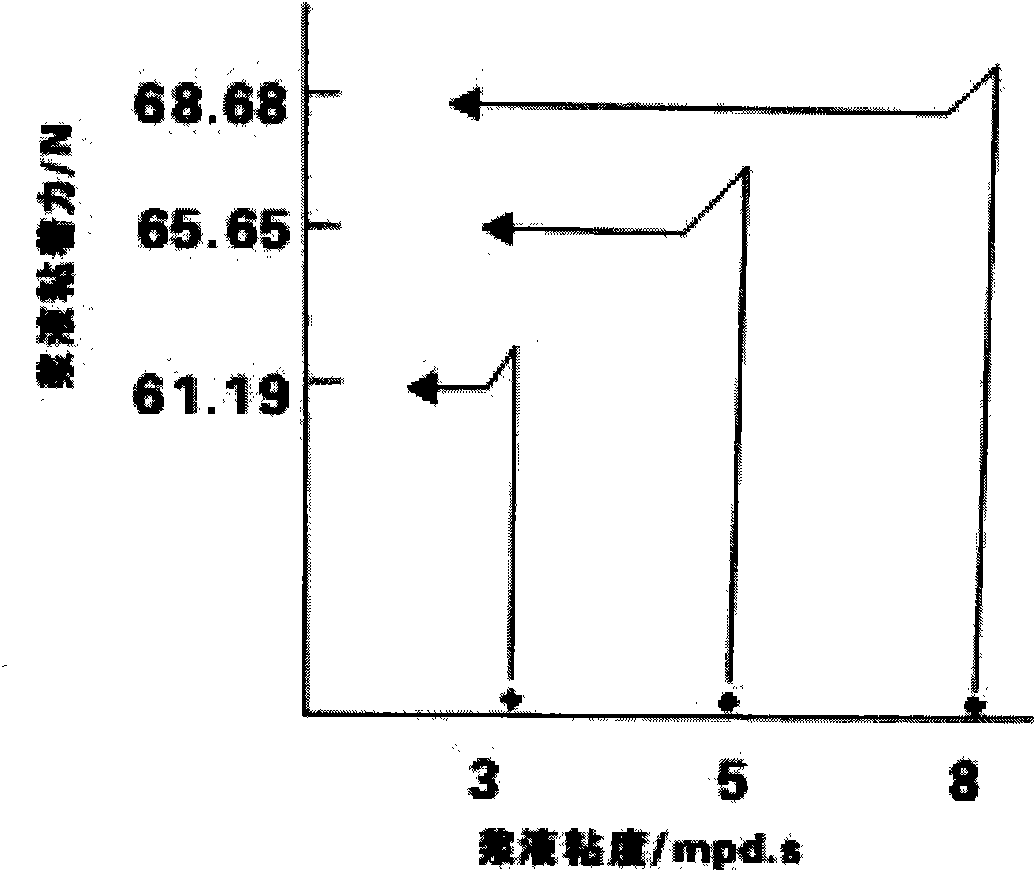

[0045] Take 150kg of corn starch, add 0.65kg of adipic acid, 0.30kg of oleic acid, 0.25kg of stearic acid, 2.5kg of glucoamylase, and 2kg of cellulase, pour it into the starch modification pot, turn on the starch modification pot device, spray Add 3kg of water, react for 30 minutes under the action of mechanical and physical shear force under normal pressure at 60°C, add 5kg of tributyl citrate, 2.5kg of sorbitol ester, 0.75kg of chitosan, and 0.15kg of guar gum Then heat up to 150°C and knead for 8 minutes to inactivate the enzyme and graft, add 1kg of sodium hydroxide (food grade) to adjust the pH value to 6-8, stop heating, stir and close the device, and discharge the reacted mixture into the material cooler Cool in medium, stand still and detect, and the measured viscosity value is below 10mpa.s (NDJ-79 type detector is measured at 95°C, 6% solid content), and the bio-enzyme modified starch (SSU-1) is obtained.

Embodiment 2

[0047] Take 150kg of corn starch, add 0.65kg of adipic acid, 0.30kg of oleic acid, 0.25kg of stearic acid, 2.5kg of glucoamylase, and 2kg of cellulase, pour it into the starch modification pot, turn on the starch modification pot device, spray Add 3kg of water, react for 40 minutes under the action of mechanical and physical shear force under normal pressure at 60°C, add 5kg of tributyl citrate, 2.5kg of sorbitol ester, 0.75kg of chitosan, and 0.15kg of guar gum Then heat up to 150°C and knead for 8 minutes to inactivate the enzyme and graft, add 1kg of sodium hydroxide (food grade) to adjust the pH value to 6-8, stop heating, stir and close the device, and discharge the reacted mixture into the material cooler Cool in medium, stand still and detect, and the measured viscosity value is below 5mpa.s (NDJ-79 type detector is measured at 95°C, 6% solid content), and the bio-enzyme modified starch (SSU-2) is obtained.

Embodiment 3

[0049] Take 150kg of potato starch, add 0.40kg of sebacic acid, 0.60kg of myristic acid, 0.50kg of lauric acid, 1.5kg of α-amylase, 1.2kg of acid protease, 1kg of lipase, pour it into the starch modification pot, and start the starch modification Pot device, spray 1kg of water, react for 30 minutes under the action of mechanical shear force at 60°C under normal pressure, add 2.50kg of butyl stearate, 5kg of water-soluble polyester, 1kg of chitin, and 0.2kg of gum arabic Heat up to 150°C and stir for 10 minutes to inactivate the enzyme and graft, add 1.25kg of sodium hydroxide (food grade) to adjust the pH value to 6-8, stop heating and stirring, close the device, and discharge the reacted mixture into the material cooler Cool in medium, stand still and detect, the measured viscosity value is below 8mpa.s (NDJ-79 type detector is measured at 95 ℃, 6% solid content rate).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com