Method for preparing nano powder material

A technology of nano-powder and powder material, which is applied in nano-structure manufacturing, nano-technology, nano-technology and other directions, can solve the problems of powder particle size distribution and unsatisfactory sintering activity, and achieve social and economic benefits. Narrow distribution and high sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

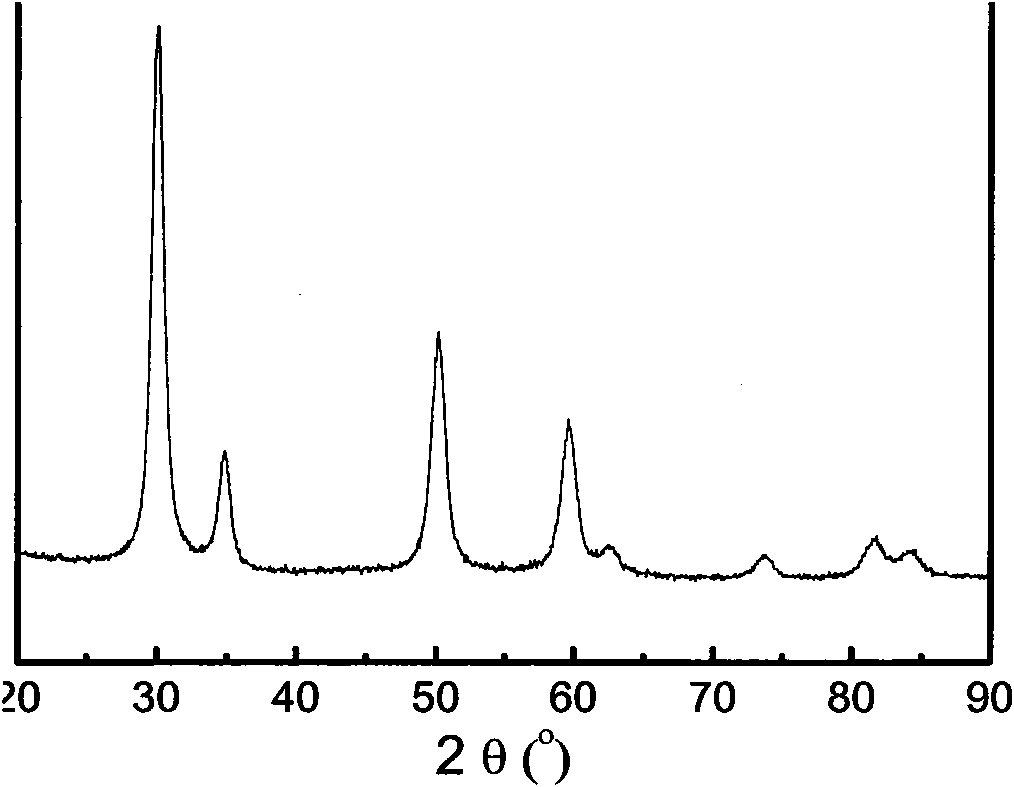

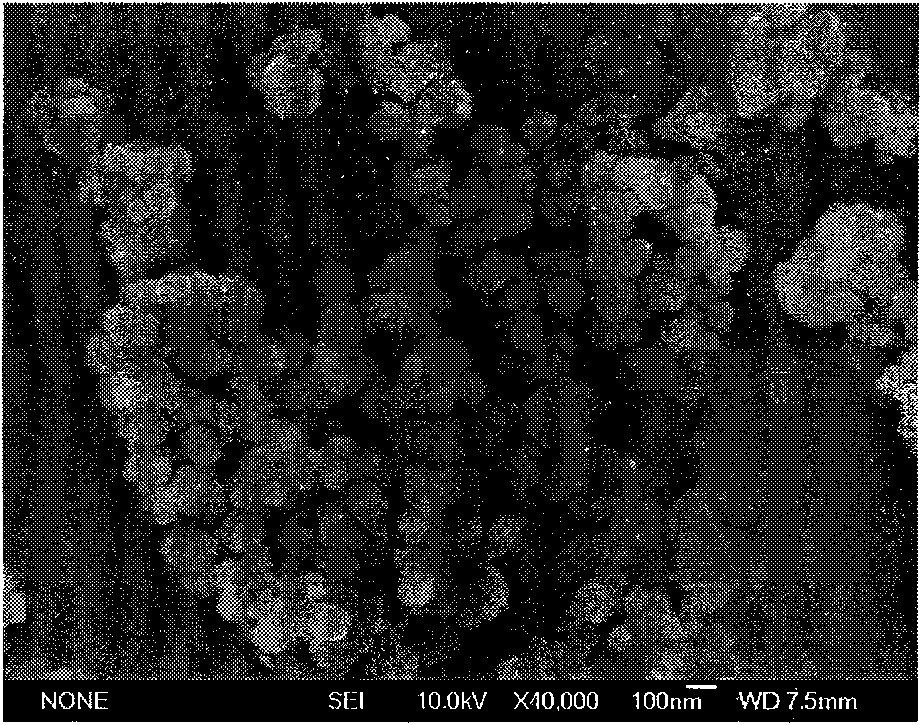

[0030] Nano 8YSZ (8mol% Y 2 O 3 -92mol% ZrO 2 ) preparation:

[0031] First start with Y(NO 3 ) 3 ·6H 2 O and ZrO (NO 3 ) 2 ·8H 2 O is used as raw material, and absolute ethanol is used as solvent to prepare 400 mL of nitrate mixed solution of yttrium nitrate and zirconium oxynitrate with a total metal ion concentration of 0.10 mol / L. Using ethanol as a solvent, 400 mL of an ethanolamine ethanol solution with an ethanolamine concentration of 1.0 mol / L was prepared, and 1.5 wt.% PEG6000 was added as a surfactant based on the mass of the final synthetic powder, and stirred and heated to dissolve it to form a transparent solution. Under constant stirring, the above-mentioned nitrate mixed solution was added to the ethanolamine ethanol solution to obtain a precipitated suspension; continued stirring for 30 minutes, allowed to stand for ageing for 12 hours, then filtered, and washed 3 times with absolute ethanol to obtain the precipitate, Vacuum dry at 75°C for 6h, grind a...

Embodiment 2

[0034] Nano ZrO 2Preparation of:

[0035] First, ZrO (NO 3 ) 2 ·8H 2 O is used as raw material, and anhydrous isopropanol is used as solvent to prepare 400 mL of nitrate mixed solution of yttrium nitrate and zirconium oxynitrate with a total metal ion concentration of 0.05 mol / L. Using isopropanol as a solvent, prepare 400 mL of an ethanolamine isopropanol solution with an ethanolamine concentration of 0.25 mol / IL, and add 0.5 wt.% PEG2000 based on the final synthetic powder mass as a surfactant, stir and heat to dissolve it A clear solution was formed. Under constant stirring, the above-mentioned nitrate mixed solution was added to the ethanolamine isopropanol solution to obtain a precipitation suspension; continued stirring for 30 minutes, allowed to stand for ageing for 6 hours, then filtered, and washed 3 times with anhydrous n-butanol The precipitate was obtained, vacuum-dried at 110 °C for 6 hours, ground and then calcined at 600 °C for 4 hours; using ethanol as sol...

Embodiment 3

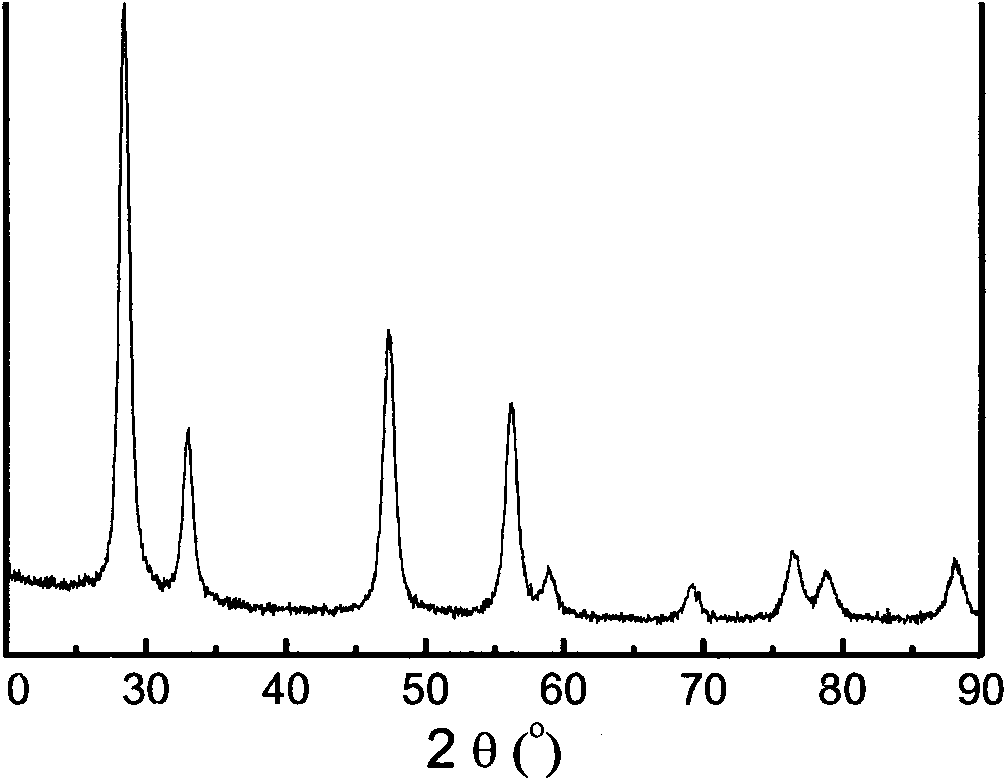

[0038] Nano 10ScSZ-1CeO 2 (10mol% Sc 2 O 3 -89mol% ZrO 2 -1mol% CeO 2 ) preparation:

[0039] First start with Sc(NO 3 ) 3 ·4H 2 O, Ce (NO 3 ) 3 ·6H 2 O and ZrO (NO 3 ) 2 ·8H 2 O is used as raw material, and absolute ethanol is used as solvent to prepare 400 mL of nitrate mixed solution of yttrium nitrate and zirconium oxynitrate with a total metal ion concentration of 0.25 mol / L. Using ethanol as a solvent, 400 mL of an ethanolamine ethanol solution with an ethanolamine concentration of 1.5 mol / L was prepared, and 3.0 wt.% PEG6000 was added as a surfactant based on the mass of the final synthetic powder, and stirred and heated to dissolve it to form a transparent solution. Under constant stirring, the above-mentioned nitrate mixed solution was added to the ethanolamine ethanol solution to obtain a precipitated suspension; the stirring was continued for 15 minutes, allowed to stand for ageing for 2 hours, then filtered, and washed 3 times with absolute ethanol to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com