Method for preparing amphiphilic gradient copolymer

A gradient copolymer and amphiphilic technology, applied in the fields of polymer chemistry and emulsion polymerization, to overcome the instability of latex, the preparation method is simple and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] First disperse 2.5g of dodecylmercaptan and 0.27g of tetrapropylammonium bromide in a mixed solvent composed of 5ml of water and 40ml of acetone, then add 0.5g of sodium hydroxide and stir to dissolve it, and wait for the mixture to drop to Then add 0.95g of carbon disulfide at room temperature, stir for 30 minutes, add 1.91g of dibromopropionic acid, stir and react at room temperature for more than 12 hours, then let it naturally volatilize to 1 / 4 of its original volume, then add hydrochloric acid (2mol / L, 50mL) was slowly acidified, diluted with 150mL of water, filtered and washed to obtain the product, and finally recrystallized with petroleum ether and n-hexane to obtain the basic RAFT reagent S-1-dodecyl-S'-(α-methyl-α'-acetic acid ) Trithiocarbonate. In the three-necked flask, add 1.75 g of S-1-dodecyl-S'-(α-methyl-α'-acetic acid) trithiocarbonate, 4.4 g of dioxane, and 2.16 g of acrylic acid after passing nitrogen gas for 15 minutes. , V-501 initiator 0.14g, ful...

Embodiment 2

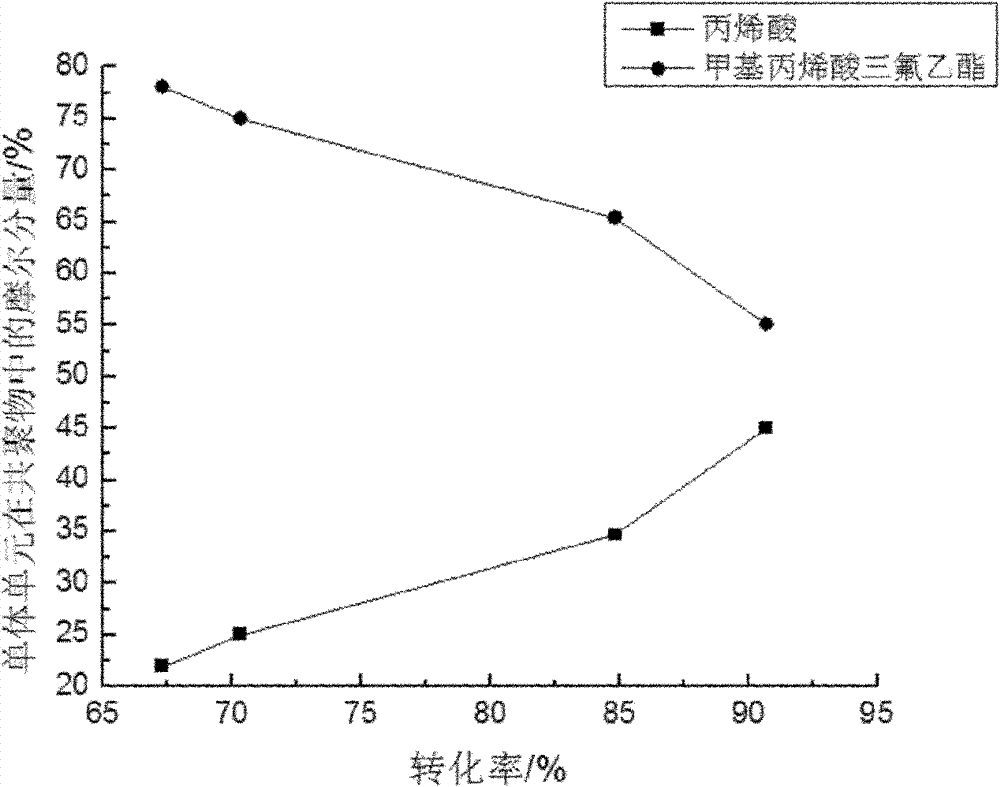

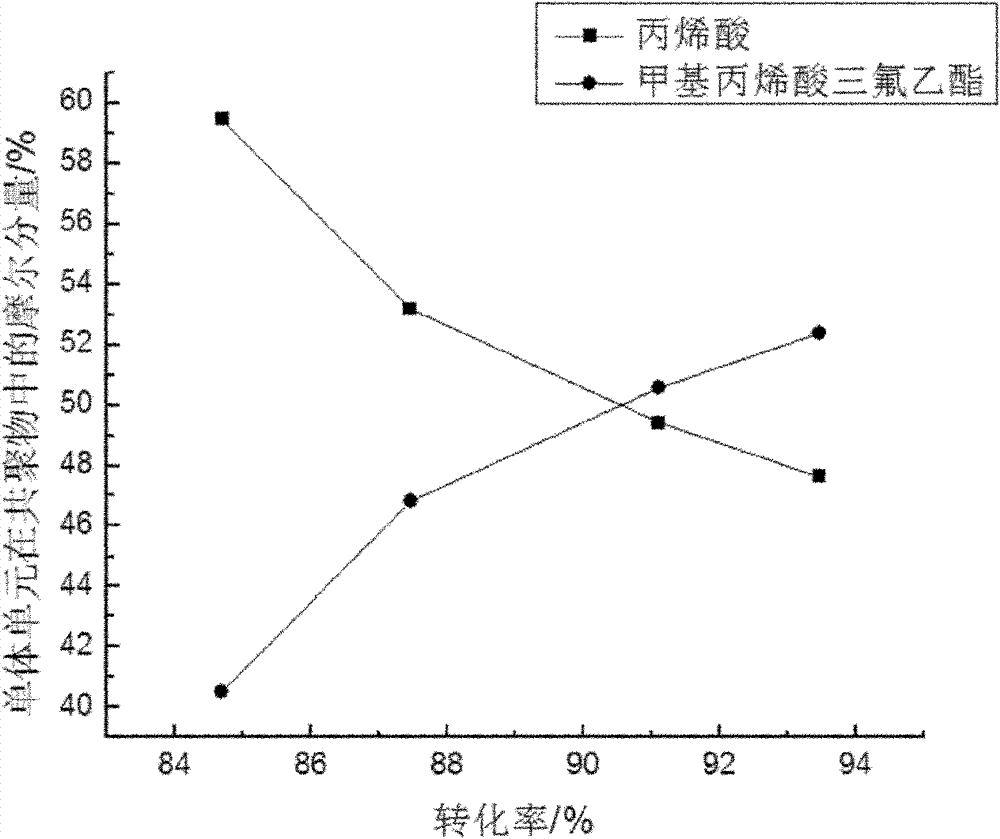

[0042] Add 31.16g of water, 1.64g of acetone and 0.2346g of S-1-dodecyl-S'-[(1,3,5,7,9,11,13-heptacarboxy) -Tetradecyl] trithiocarbonate (obtained by the method of Example 1), after stirring and dissolving fully, add 2.88g of acrylic acid, start heating after fully mixing. When the temperature reaches 60°C, add 0.042g of initiator 4,4'-azobis(4-cyanovaleric acid) to dissolve, and start to add dropwise at a rate of 2.1ml / h using a micro-sampling pump after the water bath is heated to 70°C 5.04g of trifluoroethyl methacrylate, heat preservation reaction for 6h. The copolymer emulsion is demulsified with a calcium chloride solution, and then filtered, washed and vacuum-dried to obtain a copolymer product. Depend on image 3 can be seen by 1 H NMR analysis of the relationship between the molar weight of acrylic acid and trifluoroethyl methacrylate monomer units in the copolymer and the conversion rate. The obtained gradient copolymer was dissolved in a mixed solvent of dioxane...

Embodiment 3

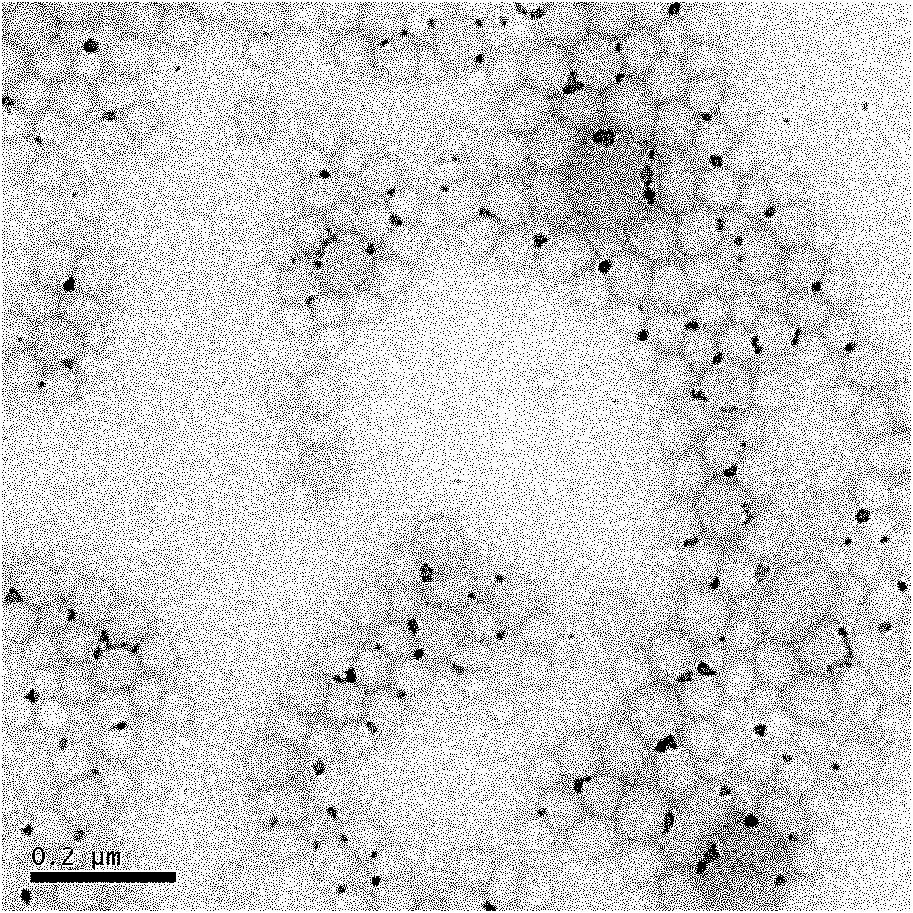

[0044] In the three-necked flask, 31.16g of water, 1.64g of tetrahydrofuran and 0.2346g of S-1-dodecyl-S'-[(1,3,5,7,9,11,13-heptacarboxy) were added after passing nitrogen gas for 15 minutes -Tetradecyl] trithiocarbonate (obtained by the method of Example 1), after stirring and dissolving fully, add 2.88g of acrylic acid, start heating after fully mixing. When the temperature reaches 60°C, add 0.042g of initiator 4,4'-azobis(4-cyanovaleric acid) to dissolve, and start to add dropwise at a rate of 2.1ml / h using a micro-sampling pump after the water bath is heated to 70°C 5.04g of trifluoroethyl methacrylate, heat preservation reaction for 6h. The copolymer emulsion is demulsified with a calcium chloride solution, and then filtered, washed and vacuum-dried to obtain a copolymer product. The obtained gradient copolymer was dissolved in a mixed solvent of dioxane and water (volume ratio 94:6), and stirred for more than 12 h to completely dissolve into monomolecular dispersion. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com