Method for preparing crocetin from jasmine

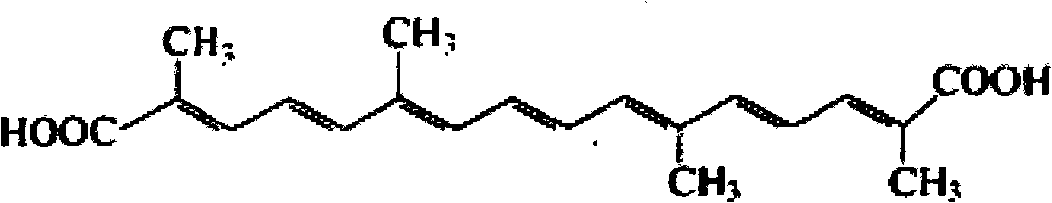

A technology of crocetin and gardenia, which is applied in the field of biological enzymolysis and multiple resin columns to prepare crocetin, can solve the problems of non-specificity, achieve mild reaction, easy control of conditions, and product purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Pulverize the gardenia, take 1kg and mix it with ph4 hydrochloric acid aqueous solution, add 3g β-glucanosidase and mix well for enzymolysis at 40°C for 3 days, then put the enzymolysis raw materials into the extraction container, add 8kgph11 sodium hydroxide aqueous solution, stir and extract 2 hours, extract 3 times, add 500ml of D382 anion resin to neutralize the extraction solution with hydrochloric acid, and then add 500ml of D382 anion resin for adsorption, the resin column sugar reaction is negative, and then use 450ml of 10.1% sodium hydroxide solution to elute the active ingredients, and add 300ml of 001×7 cationic resin to the eluent Column desalination, add 100ml of AB-8 macroporous resin to the lowering solution for adsorption, elute with 500ml of 80% ethanol solution, recover ethanol under reduced pressure, place crystals, filter out the crystals, dissolve in anhydrous ethanol for recrystallization, and dry to obtain saffron Acid product (yield 83%), content...

Embodiment 2

[0025] Pulverize the gardenia, take 1kg and mix it with ph6 sulfuric acid aqueous solution, add 2g β-glucanase and 6g amylase and mix for 4 days at 30°C for enzymolysis, and then put the enzymolysis raw materials into the extraction container, add 13kgph9 sodium hydroxide The aqueous solution was stirred and extracted for 5 hours, extracted twice, the extract was adjusted to neutrality with hydrochloric acid, and 500ml of D392 anion resin was added for adsorption, the resin was washed with water and the column sugar reaction was negative, and then 300ml of 1% sodium hydroxide solution was used to elute the active ingredients, and 300ml of 001×7 was added to the eluent. The cation resin column was desalted, and 100ml of ADS-4 macroporous resin was added to the beating solution for adsorption, eluted with 800ml of 60% ethanol solution, the ethanol was recovered under reduced pressure, crystallized, and the crystallized product was filtered out, dissolved in anhydrous ethanol under...

Embodiment 3

[0027] Grind the gardenia to 1kg, mix it with a pH5 citric acid aqueous solution, add 1g β-glucanase and 7g cellulase and mix for 5 days at 30°C for enzymatic hydrolysis, then put the enzymolysis raw materials into the extraction container, add 13kgph11 The aqueous sodium hydroxide solution was stirred and extracted for 5 hours, extracted twice, the extract was adjusted to neutrality with hydrochloric acid, and 500ml of D280 anion resin was added for adsorption, the resin was washed with water and the sugar reaction was negative, and then 350ml of 0.4% sodium hydroxide solution was used to elute the active ingredients. Add 300ml of 001×7 cation resin column for desalination, add 100ml of LSA-7 macroporous resin to the beating solution for adsorption, elute with 600ml of 70% ethanol solution, recover the eluate under reduced pressure, stand for crystallization, filter out the crystals, dry Ethanol refluxed, dissolved and recrystallized, and dried to obtain a safranic acid produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com