Missible oil preparation using turpentine-based vegetable oil as solvent and preparation method thereof

A turpentine-based vegetable oil and solvent technology, which is applied in the fields of botanical equipment and methods, plant growth regulators, animal repellents, etc., can solve the problems of refractory aromatic hydrocarbon degradation and low environmental protection performance, and achieves easy biodegradation and high production efficiency. , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

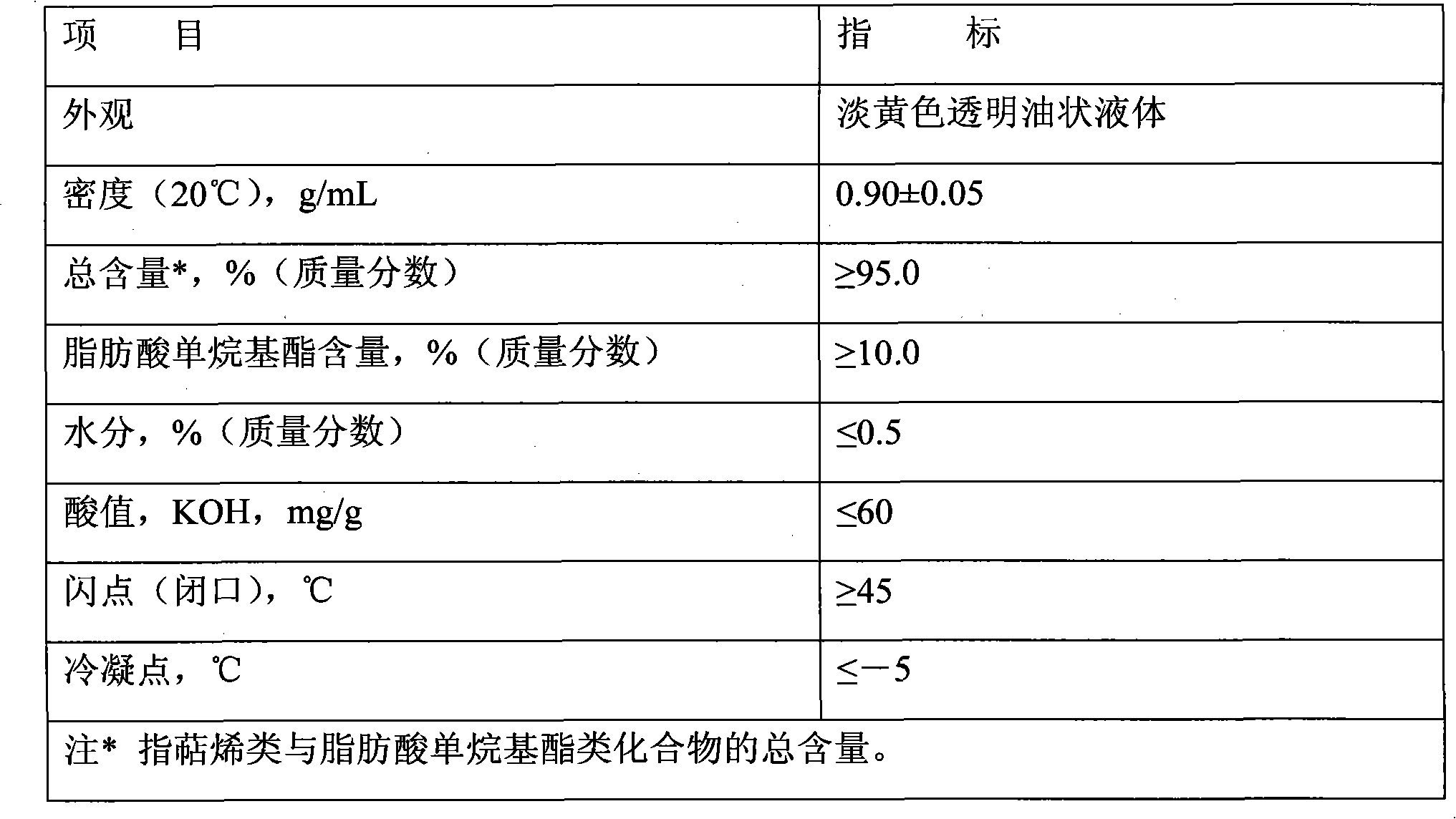

Embodiment 1

[0037] Add 18kg of avermectin, 837kg of rosin-based vegetable oil, 30kg of isooctyl alcohol, 30kg of polyoxyethylene polyoxypropylene block copolymer, 40kg of polyoxyethylene (4) lauryl ether, and dodecylbenzene in the reaction kettle. Calcium sulfonate 40kg, under the condition of 5000rpm / min, homogeneous shearing 10min disperses evenly, the vested invention 1000kg1.8% abamectin emulsifiable concentrate.

Embodiment 2

[0047] Example 2 In the reaction kettle, 50 kg of abamectin, 755 kg of rosin-based vegetable oil, 80 kg of n-octanol, 40 kg of C12-14 alcohol polyoxyethylene ether, 35 kg of sorbitan trioleate, and 35 kg of dodecyl Calcium benzenesulfonate 40kg, under the condition of 8000rpm / min, homogeneous shearing 20min disperses evenly, and the vested invention 1000kg5% avermectin emulsifiable concentrate.

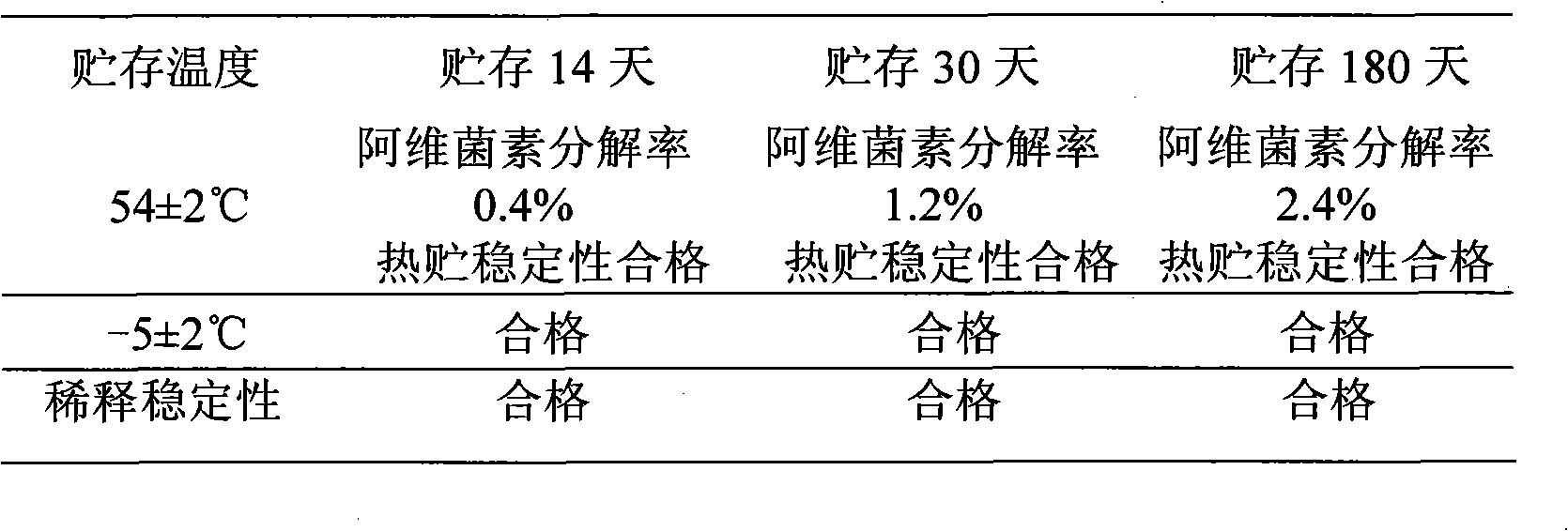

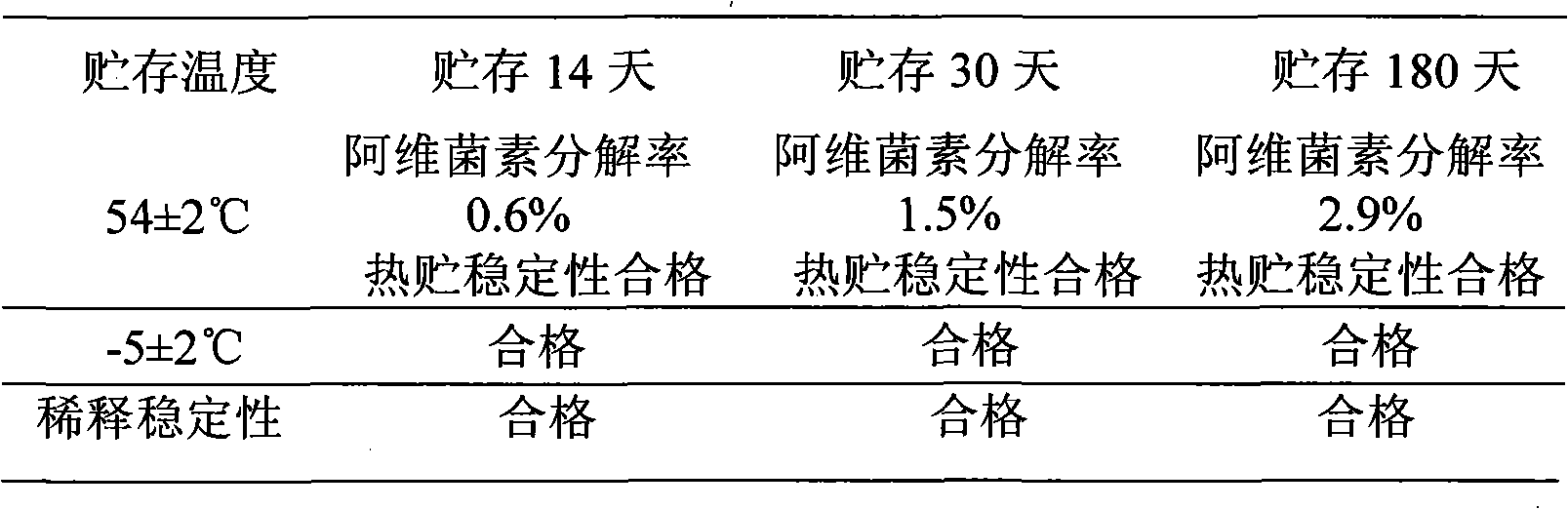

[0048] In this example, the 5% abamectin emulsifiable concentrate was stored under the condition of 54±2° C., and the low-temperature stability test was carried out under the condition of −5±2° C. The results are shown in Table 4. As can be seen from the results in Table 4, the present embodiment Abamectin emulsifiable concentrate has excellent cold and hot storage stability.

[0049] Table 4

[0050]

Embodiment 3

[0052] Add emamectin benzoate 5kg, rosin-based vegetable oil 900kg, fatty alcohol polyoxyethylene polyoxypropylene block copolymer 35kg, castor oil polyoxyethylene ether 20kg, dodecylbenzene successively in the reaction kettle Calcium sulfonate 40kg, under the condition of 3000rpm / min, homogeneous shearing 10min disperses evenly, the vested invention 1000kg0.5% emamectin benzoate emulsifiable concentrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com