Preparation method of high-purity conductive salt for super capacitor

A technology of quaternary ammonium salt cation and general formula, applied in the field of preparation of tetrafluoroborate alkyl quaternary ammonium salt, can solve the problems of easy agglomeration of dried products, reduced product yield, difficult removal of water, etc., and achieves low water content. , The effect of maintaining high yield and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

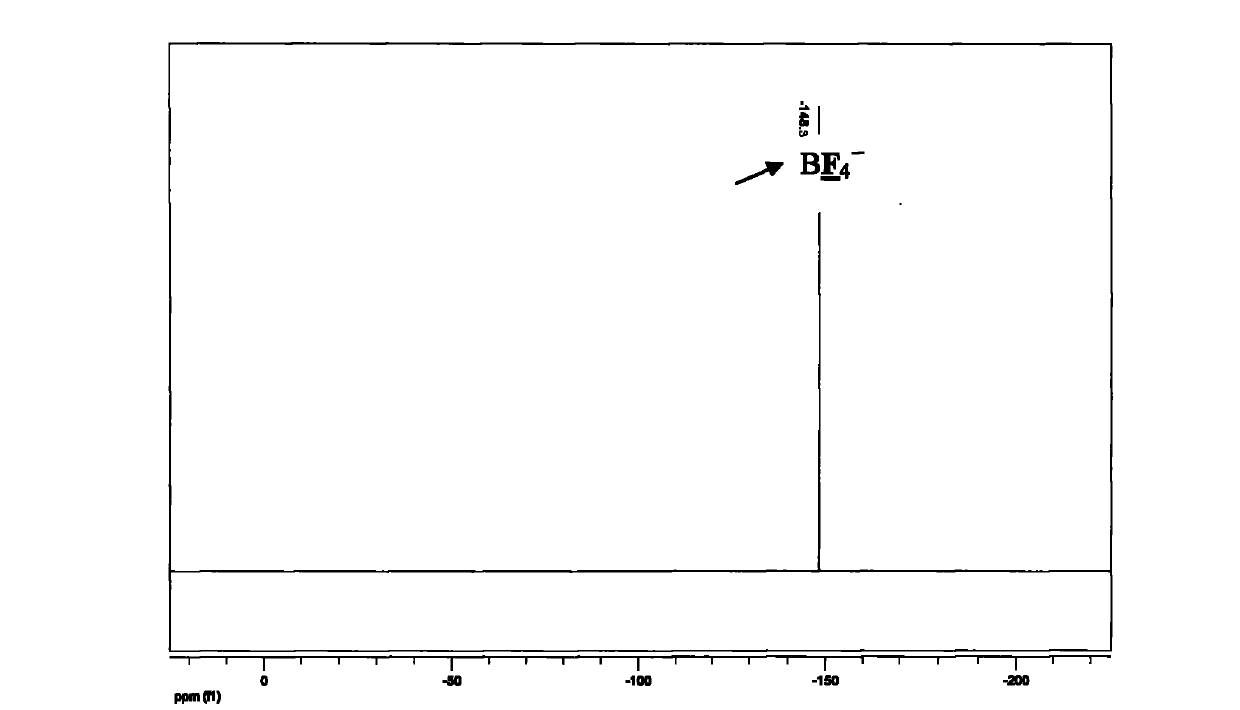

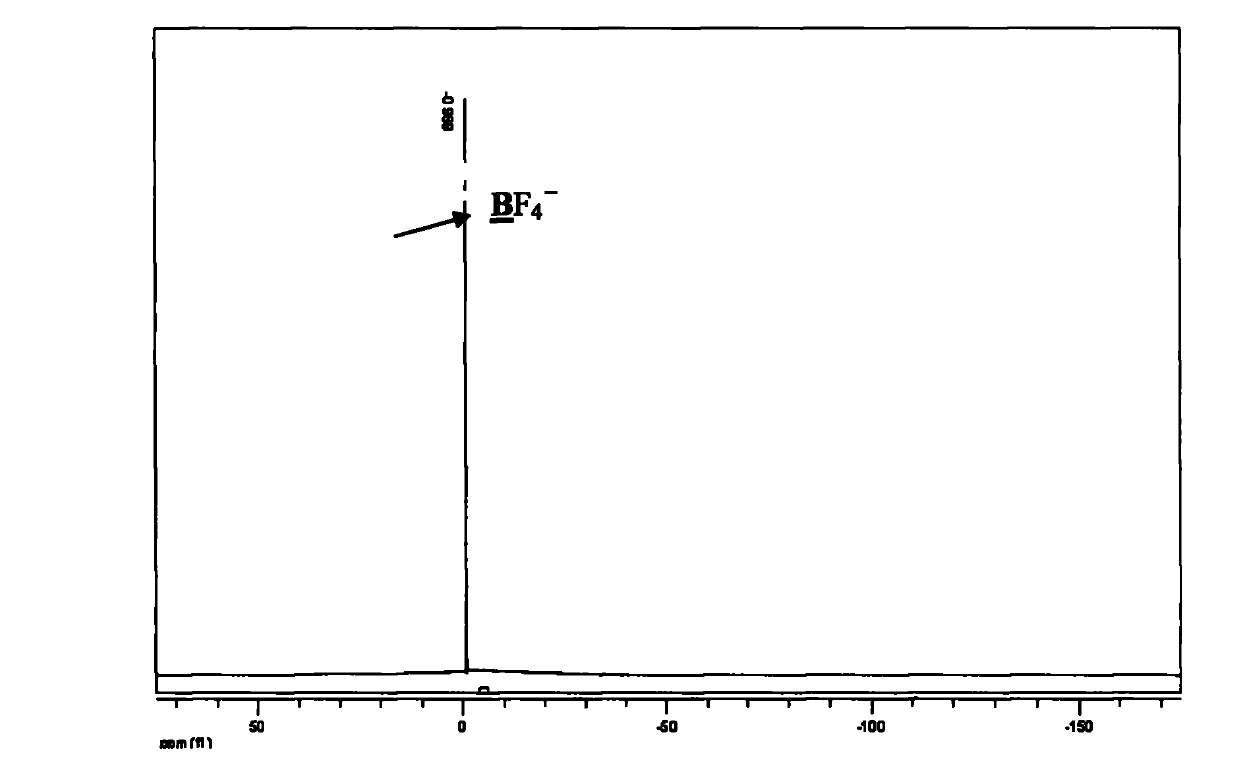

[0027] Embodiment 1: the synthesis of methyltriethylammonium tetrafluoroborate

[0028] In a 250mL stainless steel reaction kettle, add 38g (0.38mol) of triethylamine, 53g (0.59mol) of dimethyl carbonate, and 70mL of methanol in sequence, react at 130°C for 24 hours, cool to room temperature, open the reaction kettle, and collect the product solution , detected by gas chromatography, the conversion rate of triethylamine was 95%. After the collected product solution was evaporated under reduced pressure at 50° C. to remove the solvent, it was dried under reduced pressure at 50° C. and 133 Pa to obtain 65 g of solid (yield 90%). The reaction process of this step is shown in formula (9) .

[0029] In the 250mL three-neck round bottom flask, add 100mL methanol successively, the solid 38.3g (0.20mol) that last step obtains, ammonium fluoride (NH 4 F) 7.4g (0.20mol), install the reflux condenser, under continuous nitrogen flow, 50 ℃, under stirring condition, react for 10 hours, f...

Embodiment 2

[0035] Embodiment 2: comparative example

[0036] In a 250mL stainless steel reaction kettle, add 38g (0.38mol) of triethylamine, 53g (0.59mol) of dimethyl carbonate, and 70mL of methanol in sequence, react at 130°C for 24 hours, cool to room temperature, open the reaction kettle, and collect the product solution , detected by gas chromatography, the conversion rate of triethylamine was 95%. The collected product solution was evaporated to remove the solvent under reduced pressure at 50° C., and then dried under reduced pressure at 50° C. and 133 Pa pressure to obtain 65 g of solid (yield 90%).

[0037] In a 500mL PTFE round bottom flask, add 250mL of methanol solution containing 76.5g (0.4mol) of methyltriethylammonium-monomethyl carbonate, and slowly drop in 42% tetrafluoroboric acid at 0°C under electromagnetic stirring (HBF 4 ) aqueous solution 85mL, after the dropwise addition, continue at room temperature for 30min., stop stirring, and the pH of the solution is 6.0. A...

Embodiment 3

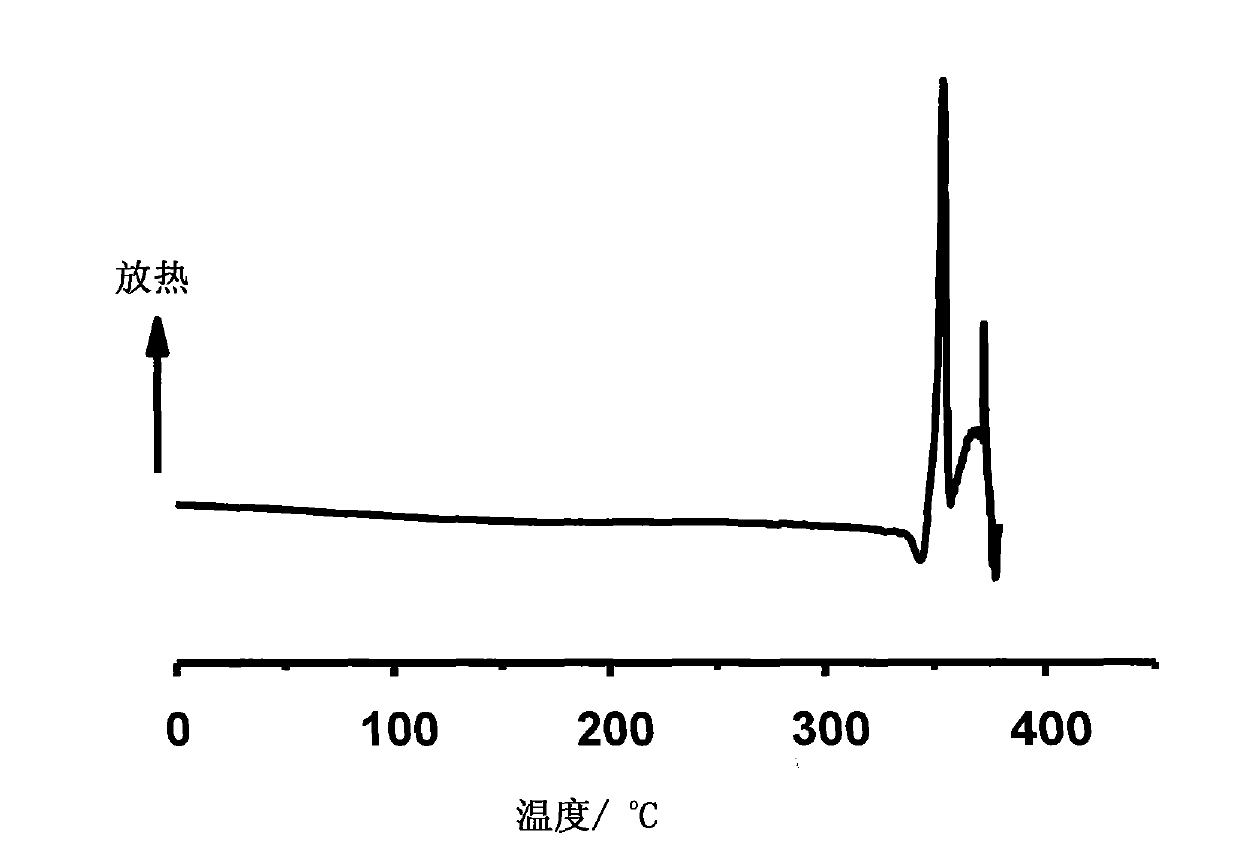

[0039] The final products obtained in Example 1 and Example 2 were compared in quality, and the results are shown in Table 1.

[0040] Table 1 The quality analysis results of methyltriethylammonium tetrafluoroborate obtained by different preparation methods

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com