Catalyst for removing hydrogen gas in carbonic oxide (CO) mixed gas by selective oxidation

A technology of selective oxidation and mixed gas, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, carbon monoxide, etc., can solve the problems of low hydrogen removal rate and high CO loss rate, and achieve short Diffusion path, reduction of side reactions, and high effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

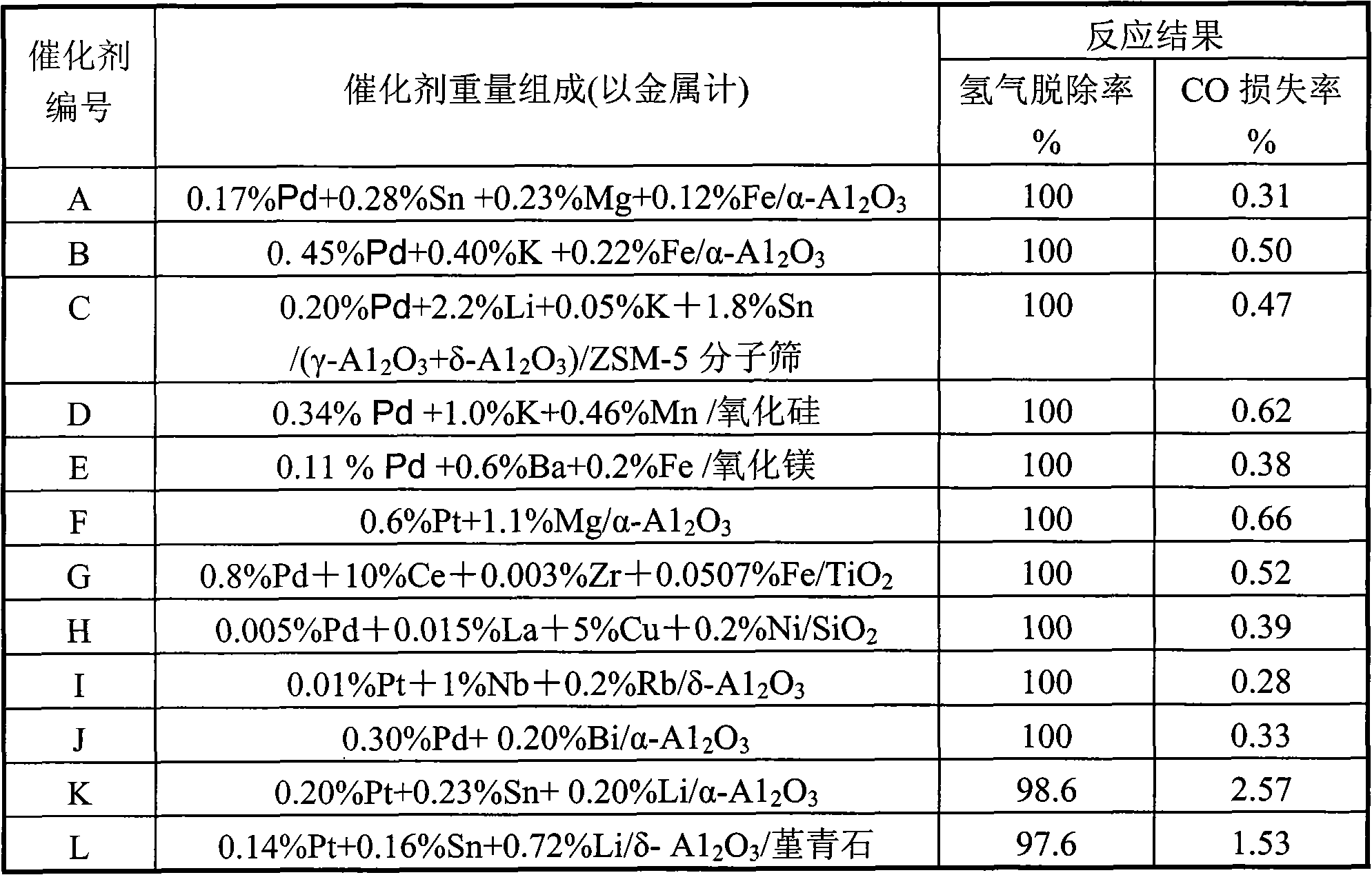

Examples

Embodiment 1

[0024] Dissolve ferric oxalate in water, heat to 70 °C, and impregnate in 3 mm of α-Al by vacuum rotation 2 o 3 pellets, and then dried at 120°C for 6 hours. SnCl 2 , magnesium nitrate and palladium nitrate were dissolved in water respectively, and the pH of the solution was adjusted to about 4 with HCl, and then the solution was heated to 80°C, impregnated on the carrier again, then dried at 140°C for 8 hours, and then heated at 450°C Calcined in air atmosphere for 4 hours, reduced in hydrogen atmosphere at 400°C for 2 hours to obtain catalyst A, whose composition is shown in Table 1. The radial distribution of the constituent elements of the catalyst is measured by EDX, and the thickness of the effective active layer is 130 microns.

Embodiment 2

[0026] Dissolve ferric nitrate in water, heat to 80 °C, and impregnate in 5 mm of α-Al by vacuum rotation 2 o 3 pellets, and then dried at 120°C for 4 hours. Dissolve potassium chloride and ammonium chloropalladate in water, adjust the solution with HCl to make the pH value about 4, then heat the solution to 80°C, impregnate it on the carrier again, and then dry it at 140°C for 4 hours, then Calcined in air atmosphere at 450°C for 4 hours, and reduced in hydrogen atmosphere at 400°C for 2 hours to obtain catalyst B, whose composition is shown in Table 1. The radial distribution of the constituent elements of the catalyst is measured by EDX, and the thickness of the effective active layer is 80 microns.

Embodiment 3

[0028] 40 grams of alumina sol (containing 20% alumina by mass ratio), 7 grams of 35% silica sol, 70 grams of 4% cyclodextrin solution, and 10 grams of cetyltrimethylammonium bromide were prepared into a slurry. Then add 0.4 grams of potassium bicarbonate and 45 grams of δ-Al with a particle size of 30 microns or less to this mixture. 2 o 3 pink. After stirring for about 20 minutes, add 2.0 g of 50% SnCl 4 As an aqueous solution, the resulting slurry was ball milled for 6 hours at room temperature to control the particle size below 20 microns. The slurry was sprayed onto ZSM-5 molecular sieve pellets with a particle size of 2.0 mm (the ratio of silicon to aluminum was 500:1, and the specific surface area was 380 square meters per gram), dried at 80°C for 4 hours, then heated to 153°C and dried again for 4 hours , and finally calcined at 900°C for 2 hours to obtain a layered composite support with a composition of 14% (γ-Al 2 o 3 +δ-Al 2 o 3 ) / 86% ZSM-5 molecular sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com