Energy saving method of industrial fluorene distillation tower used in absorber oil processing

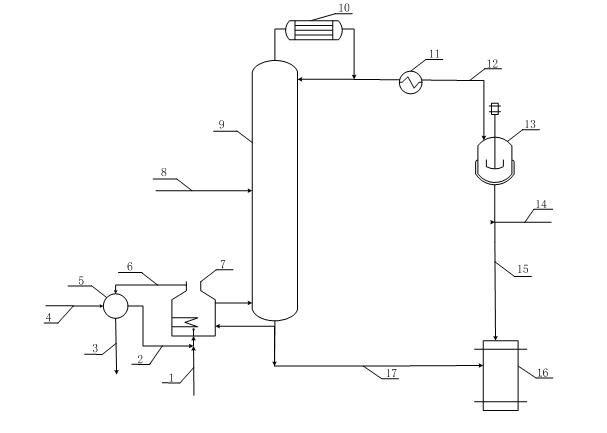

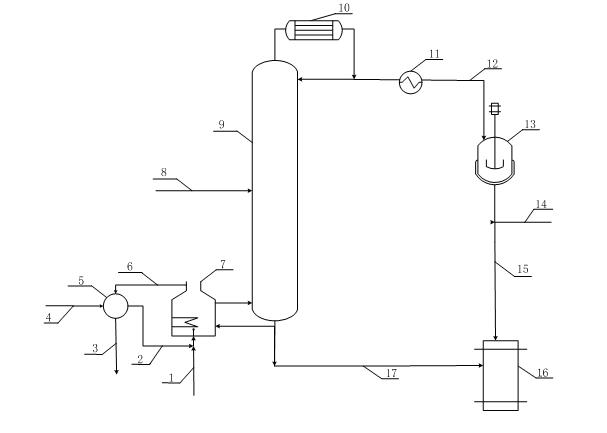

A fractionation tower and industrial technology, which is applied to the energy saving field of industrial fluorene fractionation towers, can solve the problems of poor automation level and high energy consumption of industrial fluorene towers, and achieve the effects of continuous production operation, stable product quality and simple process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

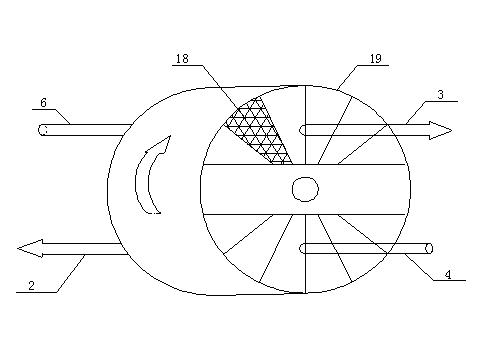

Method used

Image

Examples

Embodiment 1

[0045] The theoretical plate number of the industrial fluorene fractionation tower 9 is 40, the operating pressure at the top of the tower is normal pressure, and the reflux ratio is 6:1. The feeding position of heavy wash oil is the 15th plate, and the flow rate is 732.5kg / h. The acenaphthene fraction extracted from the top of the tower: heavy washing oil = 0.63:1 (mass ratio). After drying, the obtained industrial fluorene product is composed of 97.85% (mass fraction) by gas chromatography analyzer, and the recovery rate of dioxyfluorene reaches 82.4% %. The load of the tubular heating furnace 7 is 299.2KW, the steam generation rate of the steam generator 10 is 36kg / h, and the pressure of the steam produced is 0.4MPa.

Embodiment 2

[0047] The theoretical plate number of the industrial fluorene fractionation tower 9 is 30, the operating pressure at the top of the tower is normal pressure, and the reflux ratio is 7:1. The feeding position of heavy washing oil is the 18th plate, and the flow rate is 732.5kg / h. The acenaphthene fraction extracted from the top of the tower: heavy washing oil = 0.6:1 (mass ratio). After drying, the obtained fluorene product is composed of 97.69% (mass fraction) by gas chromatography analyzer, and the recovery rate of fluorene reaches 87.8%. The load of the tubular heating furnace 7 is 347.4KW, the steam generation rate of the steam generator 10 is 41kg / h, and the pressure of the steam produced is 0.4MPa.

[0048] The energy-saving effect of the present invention is obvious, and the energy-saving measures introduced into the process include two points: one is to use the flue gas of the tubular heating furnace to preheat the air to increase the temperature of the air entering th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com