Polysilicon film low-temperature physical vapor deposition device and method thereof

A physical vapor deposition, polysilicon thin film technology, applied in vacuum evaporation plating, coating, sputtering and other directions, can solve the problems of reducing production cost, low production efficiency, high cost, improving competitiveness and avoiding cost High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

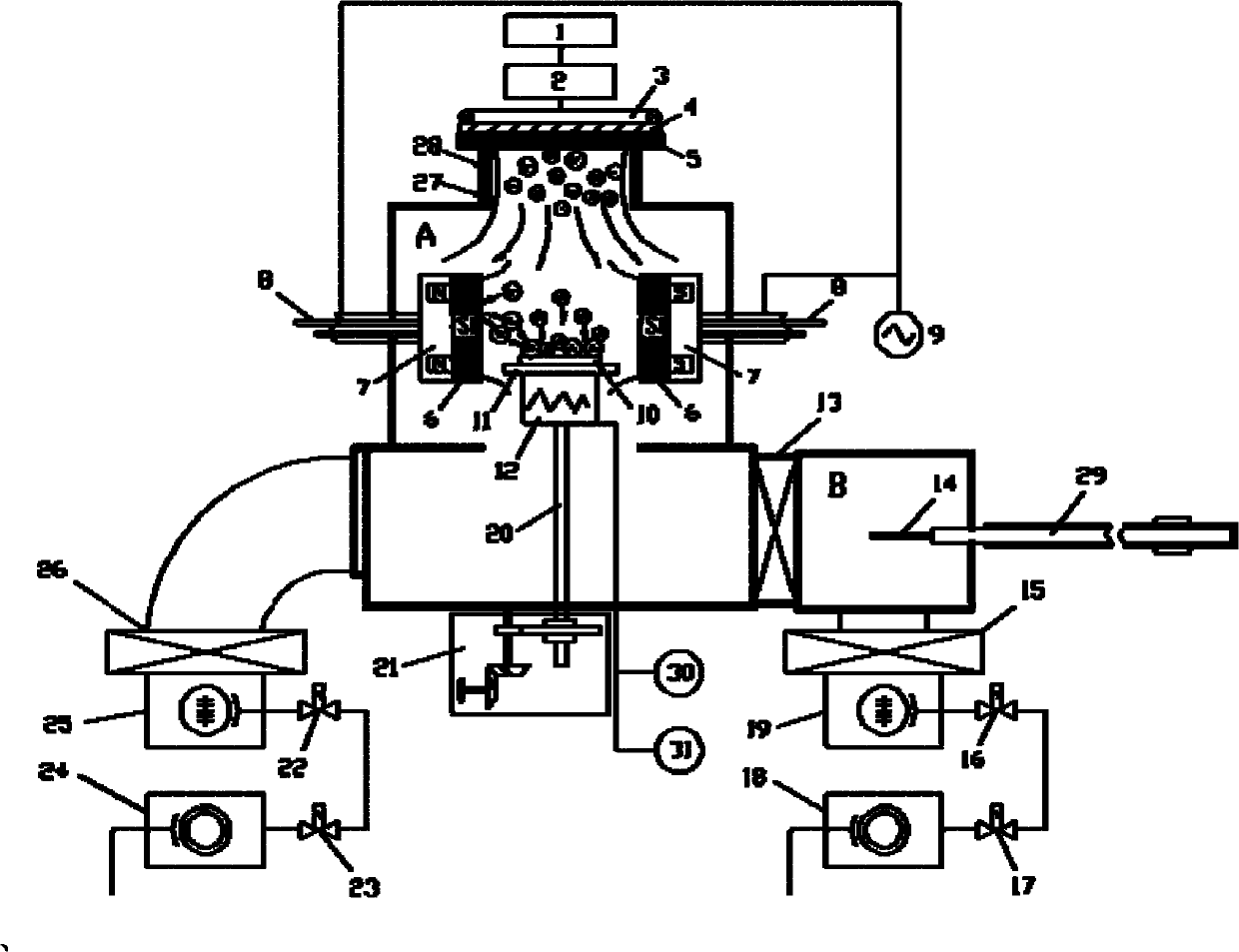

[0041] Example 1 Preparation of Polysilicon Thin Film Sample No. H30P1 and Characteristic Test

[0042] Step 1: Sample Preparation

[0043] Prepare sample 10: monocrystalline silicon silicon wafer with a diameter of φ100mm, quartz wafer with a diameter of 100mm and ordinary glass wafer with a diameter of 100mm; load it on the sample tray 11 of the auxiliary vacuum chamber B, and evacuate the auxiliary vacuum chamber B until the specified pressure value is reached Open the flapper valve 13 connecting the auxiliary vacuum chamber B and the main vacuum chamber A, and transfer the sample 10 to the main vacuum chamber A through the magnetic transfer rod 29 and the sample pallet fork 14;

[0044] Step 2: Pre-treatment of sample preparation

[0045] The background pressure of the main vacuum chamber A is pumped to a high vacuum of 2.0*10 -5 pa, the sample 10 is preheated to about 200°C, firstly, Ar is introduced into the main vacuum chamber A, and the air pressure reaches 1 Pa, the...

Embodiment 2

[0054] Example 2 Preparation of Polysilicon Thin Film Sample No. B0H30P1 and Characteristic Test

[0055] Step 1: sample preparation (with step 1 in Example 1);

[0056] Step 2: Pre-treatment of sample preparation

[0057] The background pressure of the main vacuum chamber A is pumped to a high vacuum of 2.0*10 -5 pa, sample 10 is preheated to about 200°C, here the Ar bombardment step is not implemented, and H is directly injected into the main vacuum chamber A 2 The mixed gas with Ar, the flow ratio is 90sccm / 30sccm, the pressure value reaches 1Pa, and the ICP uses the power of 1500w to continuously discharge the mixed gas for 40 seconds, thus forming H 2 Mixed gas plasma with Ar, and give the sample a bias voltage of 10-100V, where the measured bias current is 0.03A, and sample 10 is subjected to pre-deposition treatment;

[0058] Step 3: Sample preparation and deposition

[0059] Into the main vacuum chamber A, the H with a flow ratio of 60sccm / 90sccm 2 Mix the gas wit...

Embodiment 3

[0064] Example 3 Preparation of Polysilicon Thin Film Sample No. H30P1ICP8 and Characteristic Test

[0065] Step 1: Sample preparation;

[0066] Step 2: Pretreatment of sample preparation (step 1 and step 2 are the same as step 1 and step 2 in Example 2);

[0067]Step 3: Sample preparation and deposition

[0068] Into the main vacuum chamber A, the H with a flow ratio of 60sccm / 90sccm 2 Mix the gas with Ar, adjust the second slide valve 26, and set the pressure value to 1Pa. Turn on the ICP inductively coupled plasma source, the ICP power is 800w, no bias is applied to the sample 10 here, and the DC pulse magnetron sputtering twin target is turned on, the power is 200w, and the deposition time is 50 minutes;

[0069] Step 4: post-processing of sample preparation;

[0070] Step 5: Take out the sample (step 4 and step 5 are the same as step 4 and step 5 in Example 1).

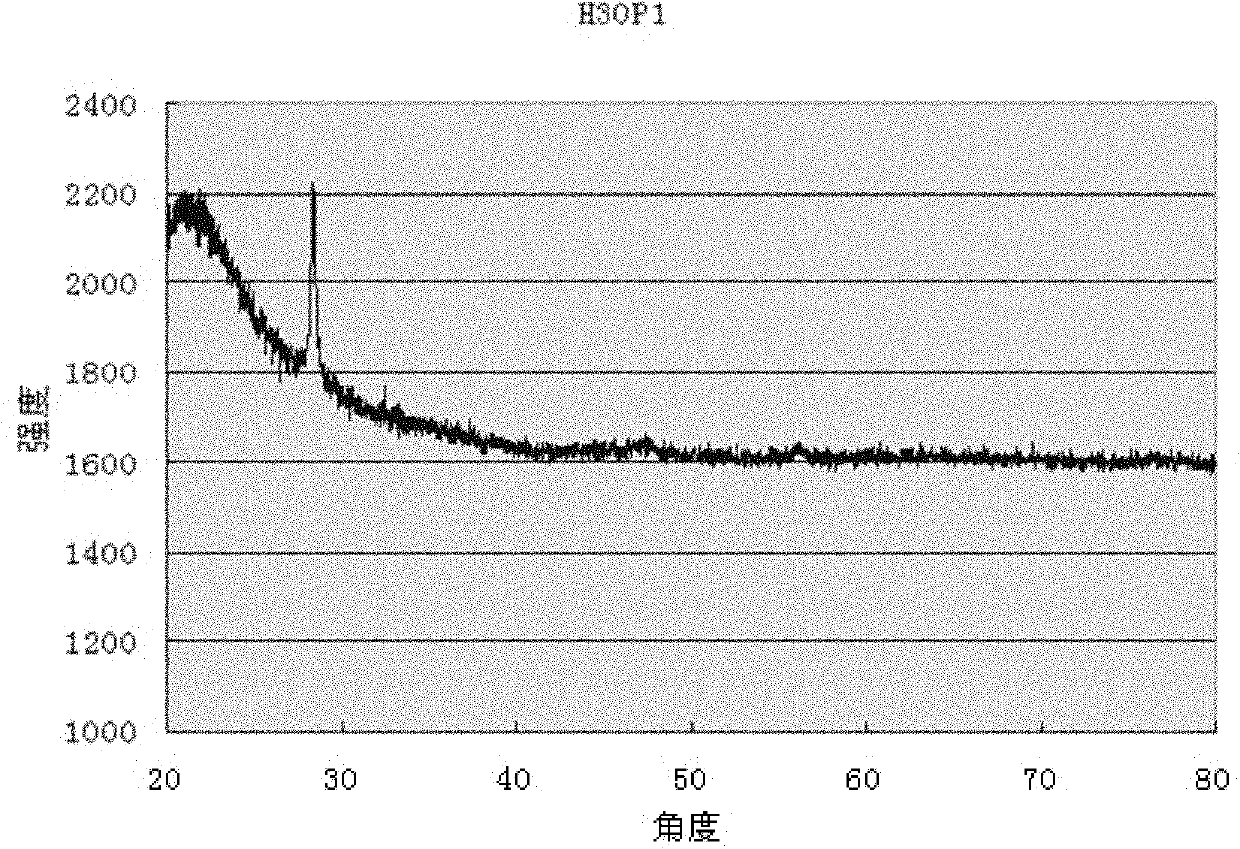

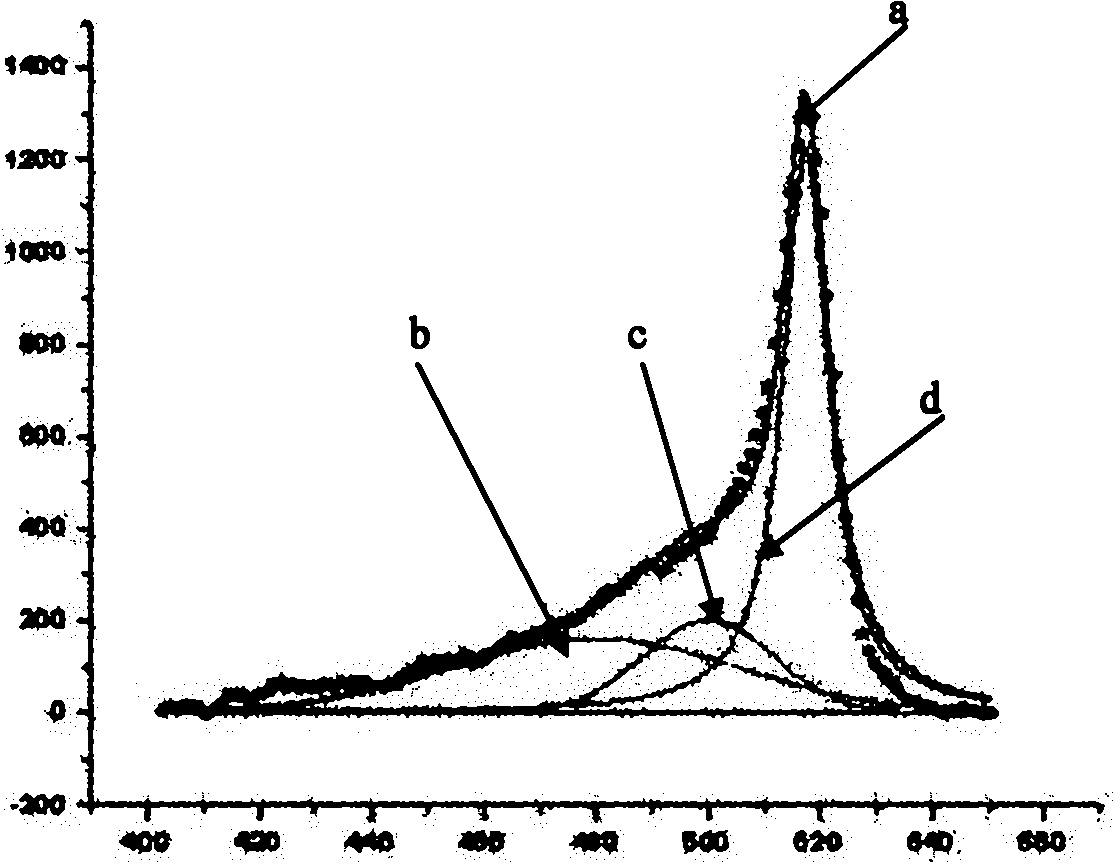

[0071] X-ray diffractometer (Cu K α Radiation, λ=0.15406nm) for structural analysis of the prepared film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com