Novel high-temperature resistant phenylacetylene terminated poly (acetenyl-silane) and preparation method thereof

A phenylacetylene and ethynyl technology, which is applied in the field of new high-temperature-resistant phenylacetylene-terminated poly(ethynyl-silane) and its preparation, can solve the problems of inability to meet the higher requirements of aerospace technology and the decline of thermal oxidation stability, etc. Achieve the effects of easy control of reaction conditions, short reaction time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

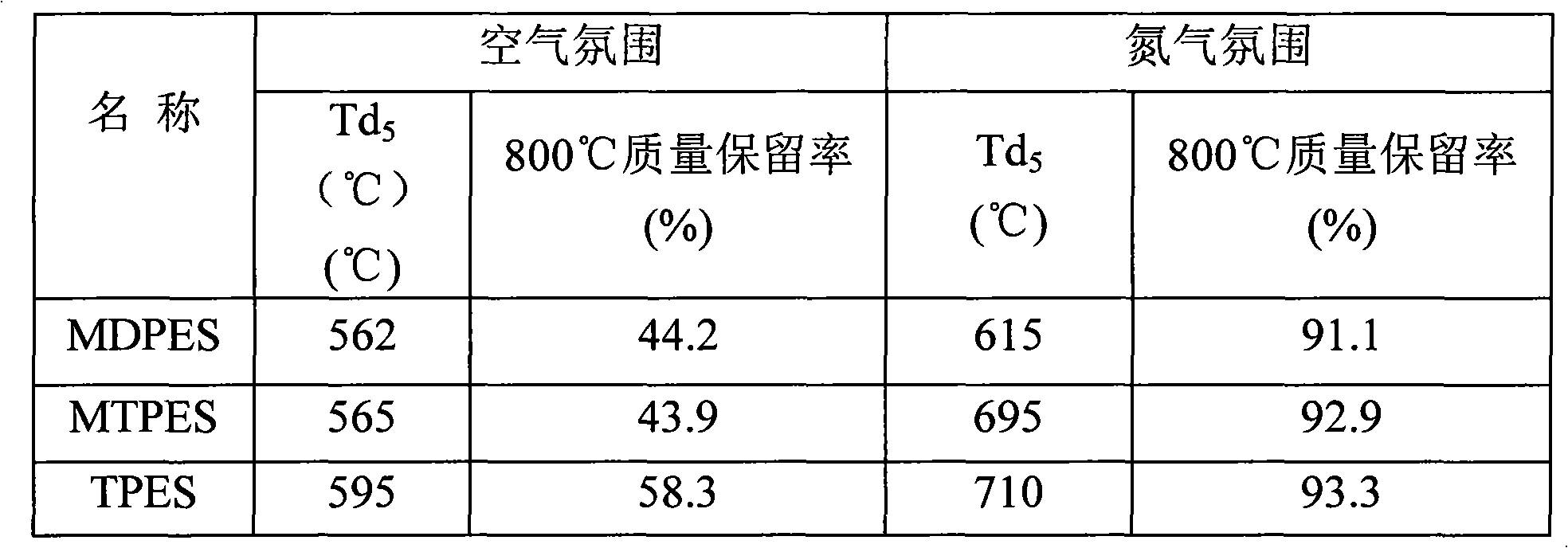

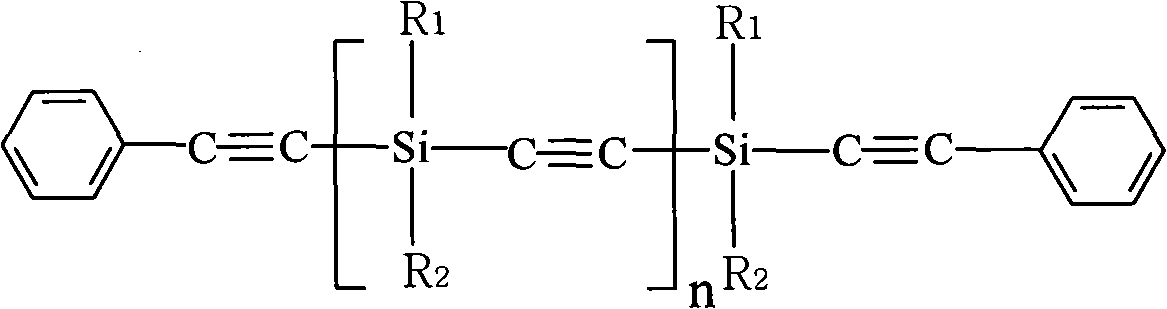

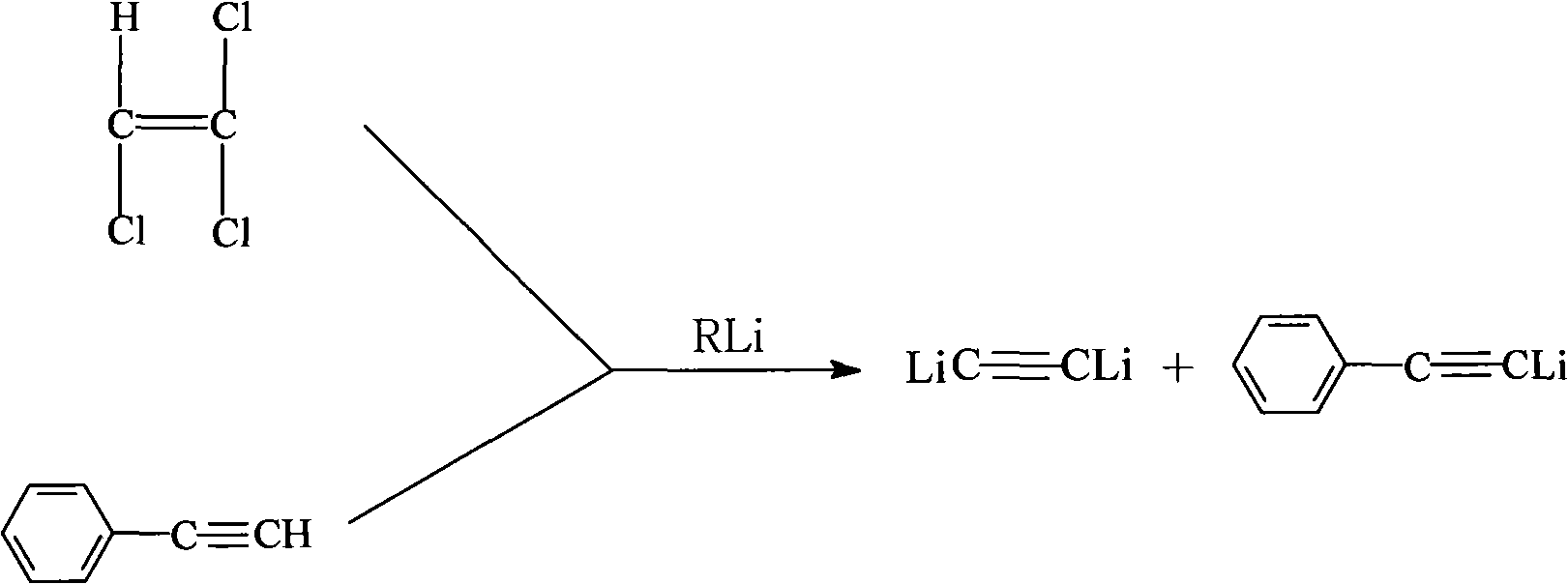

[0027] Dissolve 10mmol of phenylacetylene and 45mmol of trichlorethylene in 45ml of tetrahydrofuran, add 145mmol of butyllithium reagent dropwise with a constant pressure funnel, dropwise for 40 minutes, and react at -30°C for 4 hours after the dropwise addition. Then, 50 mmol of methylhydrogendichlorosilane was dissolved in 20 ml of tetrahydrofuran and added dropwise to the mixture of ethynyl dilithium and phenylethynyl lithium, and reacted at 10° C. for 6 hours after the dropwise addition was completed. After the reaction, add 50ml of saturated ammonium chloride solution into the reaction solution, stir fully, separate the liquids, take the upper oil phase and wash it with 30ml of saturated ammonium chloride solution until the pH value is neutral, add ether to the obtained water phase twice to extract , liquid separation, collecting and merging the resulting oil phase, and decompression distillation to remove the solvent to obtain a brown viscous resin phenylacetylene-termina...

Embodiment 2

[0029] Dissolve 30mmol of phenylacetylene and 35mmol of trichlorethylene in 40ml of tetrahydrofuran, add 135mmol of butyllithium reagent dropwise with a constant pressure funnel, dropwise for 40 minutes, and react at -20°C for 3 hours after the dropwise addition. Then, 50 mmol of dimethyldichlorosilane was dissolved in 20 ml of tetrahydrofuran and added dropwise to the mixture of ethynyl dilithium and phenylethynyl lithium, and reacted at 20° C. for 5 hours after the dropwise addition was completed. After the reaction, add 50ml of saturated ammonium chloride solution into the reaction solution, stir fully, separate the liquids, take the upper oil phase and wash it with 30ml of saturated ammonium chloride solution until the pH value is neutral, add ether to the obtained water phase twice to extract , separated, collected and combined the obtained oil phases, and distilled off the solvent under reduced pressure to obtain a brown-red viscous liquid phenylacetylene-terminated poly(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com