Electrolytic and catalytic oxidation reaction device and processing method based fluidized bed

An electrolytic catalytic oxidation and oxidation reaction technology, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of no effective standard treatment measures, high COD concentration, ultrafiltration membrane and Reverse osmosis membrane fouling and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The treatment device and method of the present invention are used to treat the sewage discharged from a circulating water system of an oil refinery (all the refinery sewage has been reused as supplementary water for the circulating water system). The main pollutants in the wastewater are COD 120mg / L (the COD values in this patent are all measured by the chromium method), BOD 5 20mg / L, total dissolved solids 2600mg / L, petroleum 3 - N < 5 mg / L.

[0025] Using the fluidized bed electrolytic catalytic oxidation reaction device and treatment method of the present invention to conduct a laboratory treatment test on the above wastewater, the wastewater treatment scale is 10L / h.

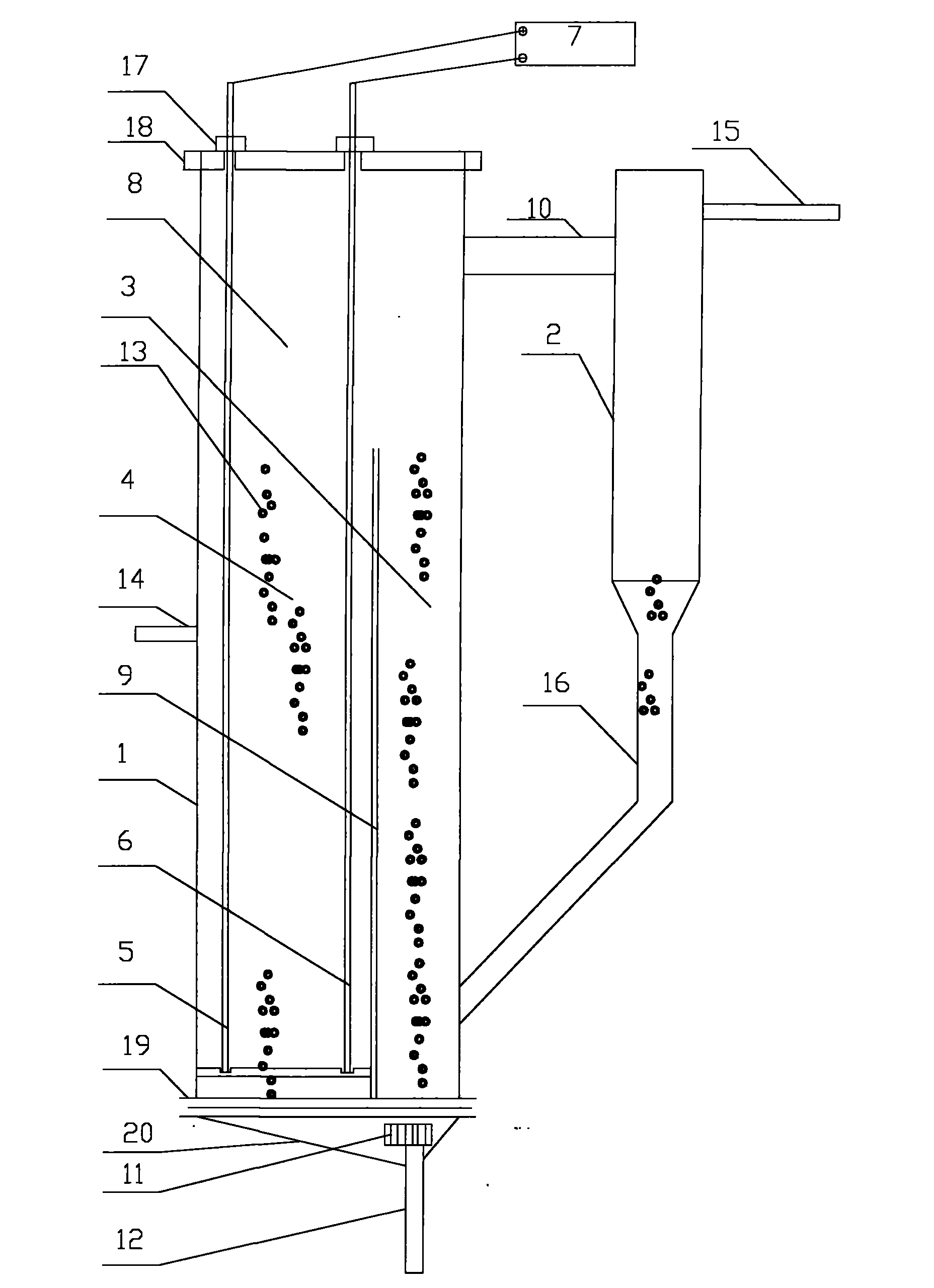

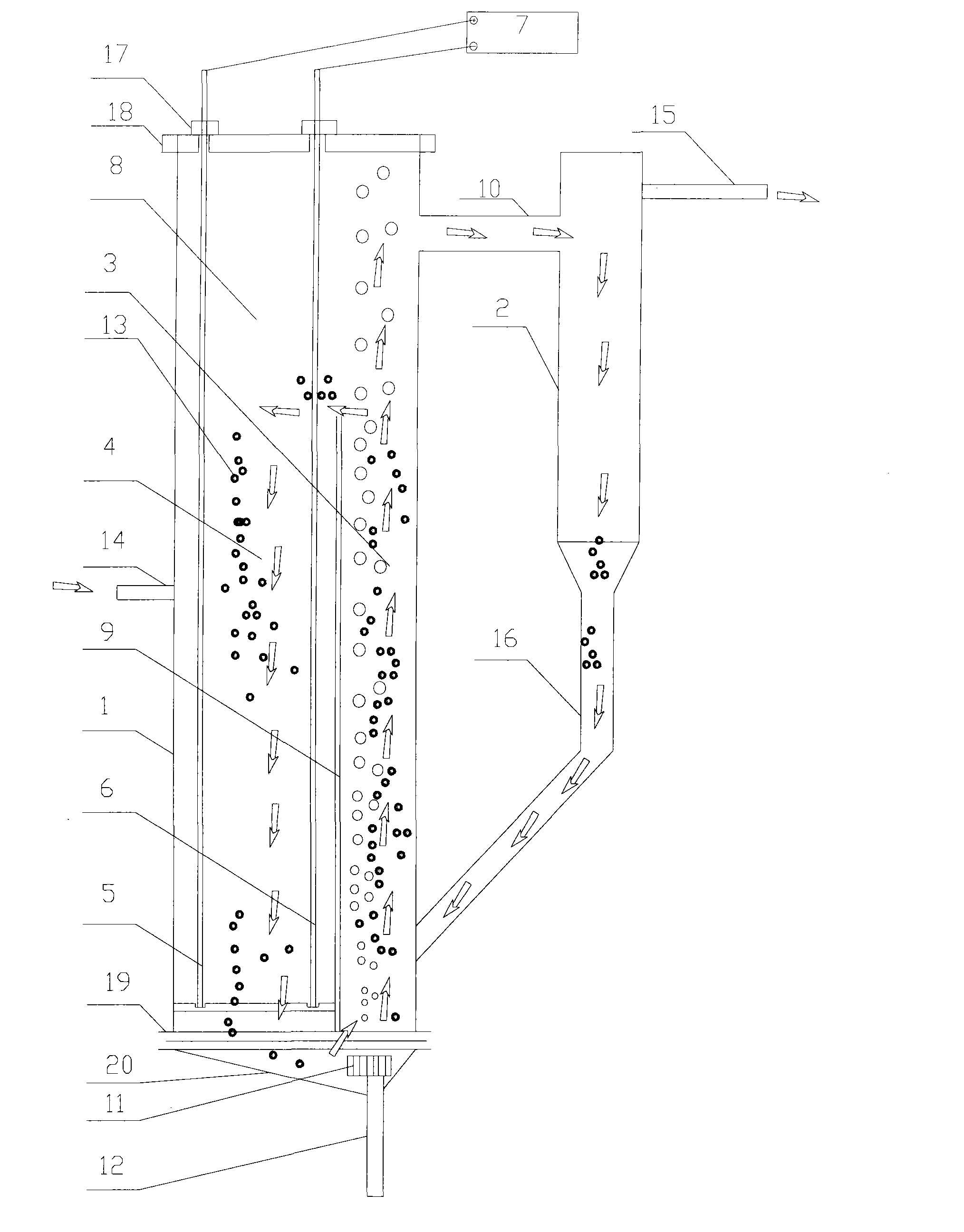

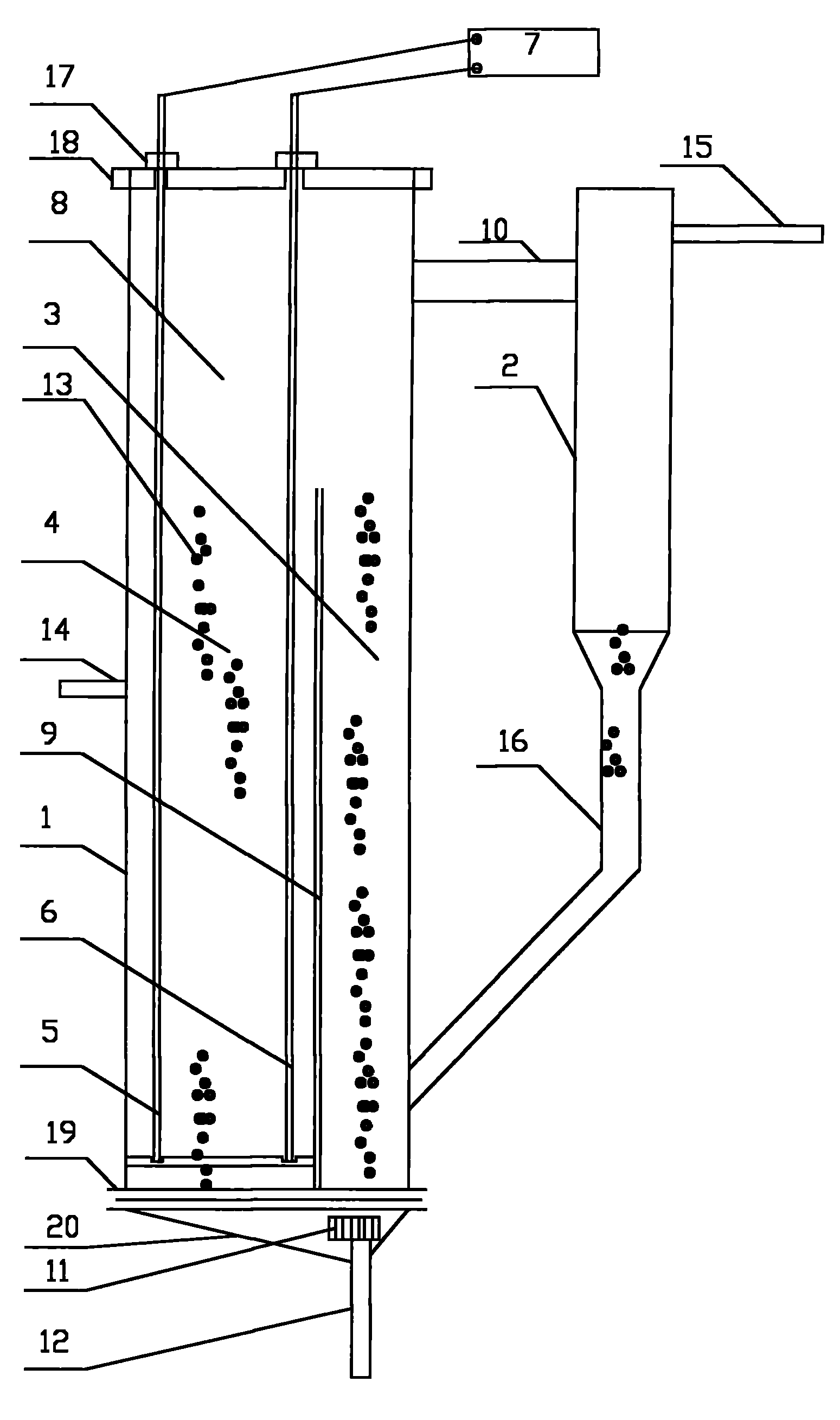

[0026] The scale and composition of the main experimental equipment: the fluidized bed electrolysis reactor is made of plexiglass, the container size is Φ150×500mm, and the total effective volume is 8.8L. The reactor is divided into a fluidized zone, a reaction zone, and an upper settling section b...

Embodiment 2

[0031] Adopt the treatment device of embodiment 1, process the same sewage as embodiment 1, change the operating condition in the treatment process to be: water inflow 10L / h; Lifting gas adopts ozone, air intake 30L / h; Carrier selects conventional active carbon particle for use, Particle size 1mm; anode uses Ti-SnO 2 Alloy plate and cathode use Ti-PbO 2 Alloy plate; the control current in the reaction zone is 8.0A.

[0032] The main treatment effects obtained are: the COD in the treated water is reduced to 35mg / L, the BOD 5 When it is reduced to 5mg / L, other pollution components are basically unchanged, and can meet the control index requirements of discharge standards and be directly discharged or used as high-quality source water for deep desalination and reuse by double-membrane method.

Embodiment 3

[0034] Adopt the treatment device of embodiment 1, process the same sewage as embodiment 1, change the operating condition in the treatment process to be: water inflow 5L / h; Lifting gas adopts ozone, air intake 20L / h; Carrier selects cobalt-loaded activated carbon particle for use (metal cobalt content 2.0%, adopt the method described in US6797184 to prepare), particle diameter 1mm; Anode adopts Ti-SnO 2 Alloy plate and cathode use Ti-PbO 2 Alloy plate; the control current in the reaction zone is 5.0A.

[0035] The main treatment effects obtained are: COD in the effluent after treatment is reduced to 30mg / L, BOD 5 When it is reduced to 5mg / L, other pollutant components are basically unchanged, which can meet the control index requirements of discharge standards and be directly discharged or used as high-quality source water for deep desalination and reuse by double-membrane method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com