Essence-safe boiler feedwater oxygenation processing method

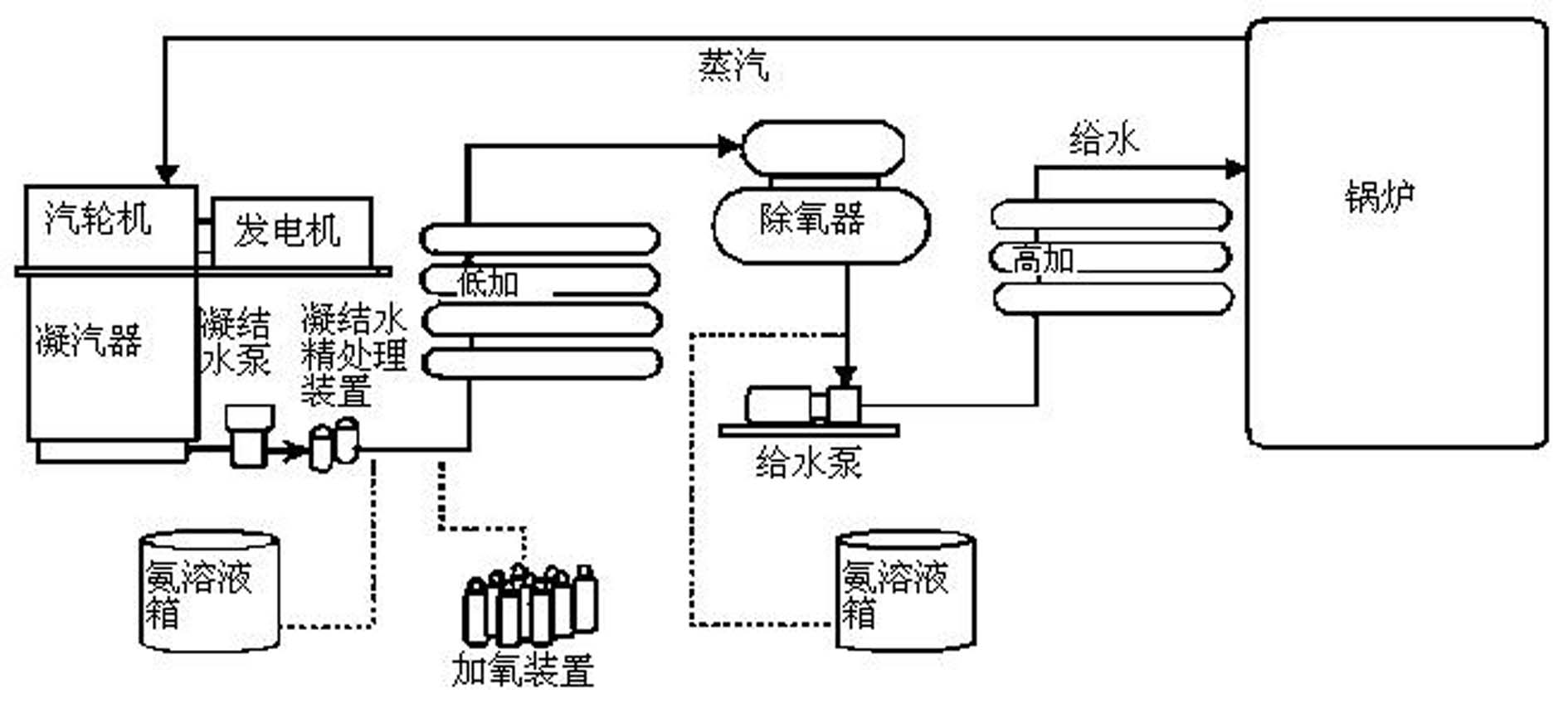

An intrinsically safe, boiler feed water technology, used in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc., can solve the problems of unsuitable copper systems, peeling scale, and low water production. , to avoid adverse effects, inhibit FAC, and prevent corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

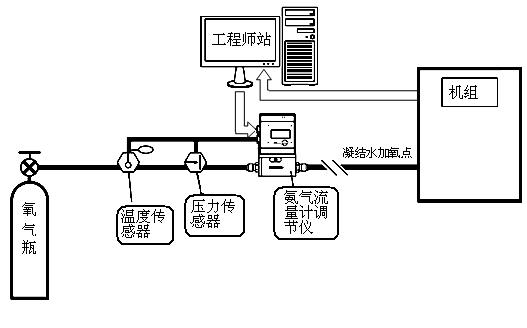

[0059] Application of the method of the present invention to a 1000MW ultra-supercritical thermal power unit

[0060] The boiler of a 1000MW coal-fired steam turbine generator set is an ultra-supercritical parameter, a vertical tube panel with a variable pressure transformer and a direct-flow Π-type boiler with an intermediate mixing header. The maximum continuous evaporation capacity (B-MCR) of the boiler is 2980t / h. The boiler outlet steam parameter is 26.25MPa(a) / 605 / 603℃, and the corresponding turbine inlet parameter is 25.0MPa(a) / 600 / 600℃.

[0061] (1) Feedwater treatment method at the initial stage of unit start-up

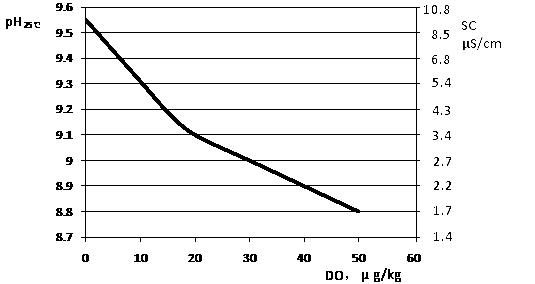

[0062] AVT (O) operation mode is adopted at the initial stage of unit start-up, that is, the feed water treatment mode is ammonia addition only. Add ammonia to adjust the pH value of the feed water at 9.3 to 9.6. When the AVT(O) operation mode is adopted at the initial stage of unit start-up, the exhaust valve of the deaerator should be in the normal open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com