Method for preparing spherical aluminum-doped nickel lithium carbonate for lithium ion battery positive electrode material

A technology for lithium-alnico-cobaltate and lithium-ion batteries, which is applied in the field of preparation of spherical aluminum-nickel-cobaltate lithium-doped lithium-ion battery anode materials, and can solve the problems of poor structural stability, difficulty in filtering flocculent precipitates, and difficulty in forming spherical large particle precipitates problems such as low cost, high tap density, controllable particle size distribution and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

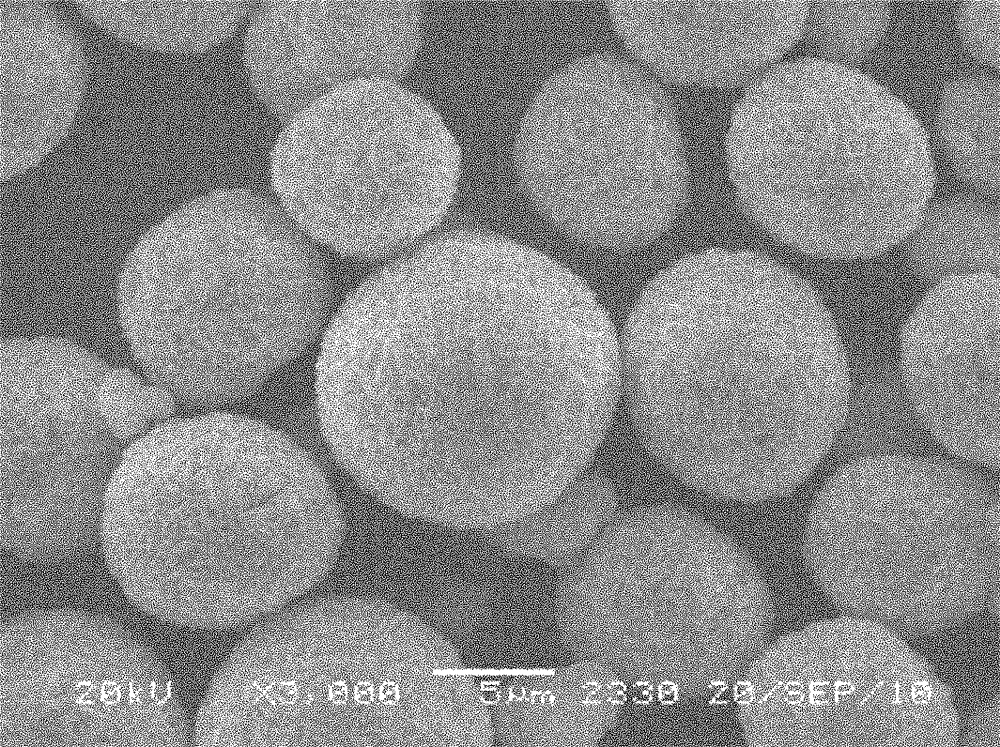

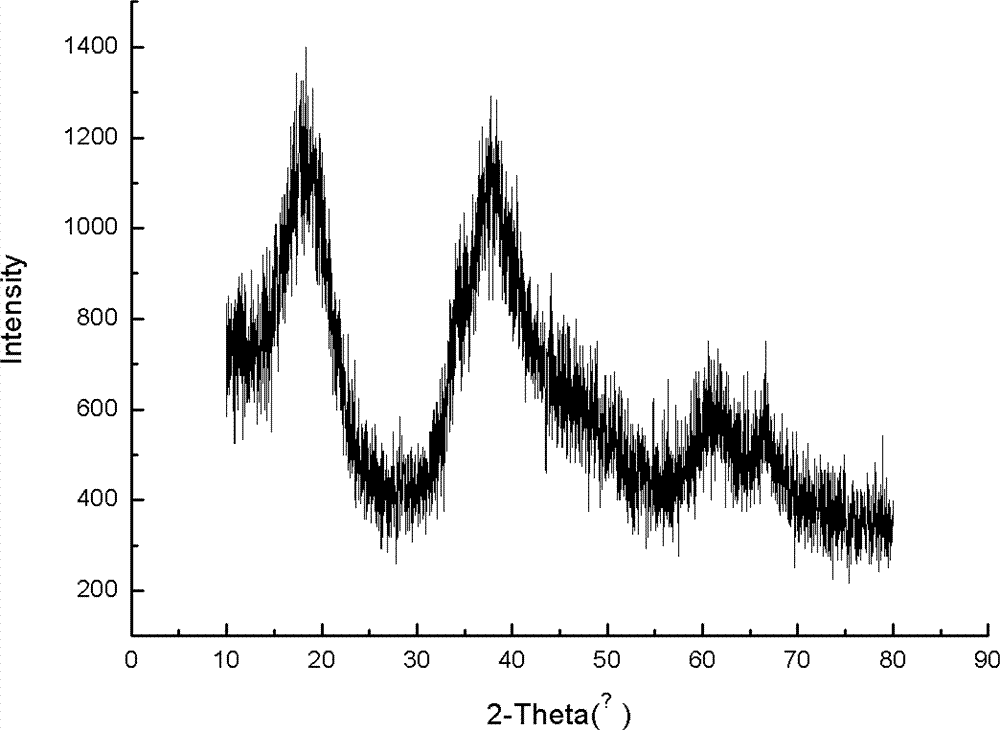

[0033] First, nickel sulfate, cobalt sulfate and aluminum sulfate are mixed in molar ratio Ni 2+ :Co 2+ : Al 3+ =0.7: 0.25: 0.05 is mixed and formulated into a 1mol / L aqueous solution, potassium persulfate is formulated into a 2mol / L aqueous solution, potassium hydroxide is formulated into 3mol / L solution 2L and 0.5L of 0.75mol / L ammoniacal liquor is added. Then, the prepared mixed salt solution and potassium persulfate solution are added into a 12L reaction kettle with a stirring device at a flow rate of 10ml / min, stirred at a speed of 450rpm and heated to 35°C to adjust the feed of the alkali solution The speed is to control the pH value of the reaction system between 11-11.5, and the reaction ends after 8 hours, and then the spherical nickel-cobalt-aluminum oxyhydroxide precursor is filtered out. Then, the spherical nickel-cobalt-aluminum oxyhydroxide was washed and filtered with deionized water for 6 times, and dried in a vacuum oven at 120° C. for 12 hours to obtain a p...

Embodiment 2

[0036] According to the method of Example 1, the precursor of nickel-cobalt-aluminum oxyhydroxide was mixed with lithium salt and then calcined at 750° C. for 10 h. After cooling, it was crushed and classified to obtain a spherical aluminum-nickel-cobalt-doped lithium material.

[0037] After inspection, the tap density of the aluminum-nickel-cobalt oxide is 2.21g / cm 3 , the average particle size is 9.127μm, the initial capacity is 184mAh / g, the first charge and discharge efficiency is 90%, and the capacity retention rate after 300 cycles is 86%.

Embodiment 3

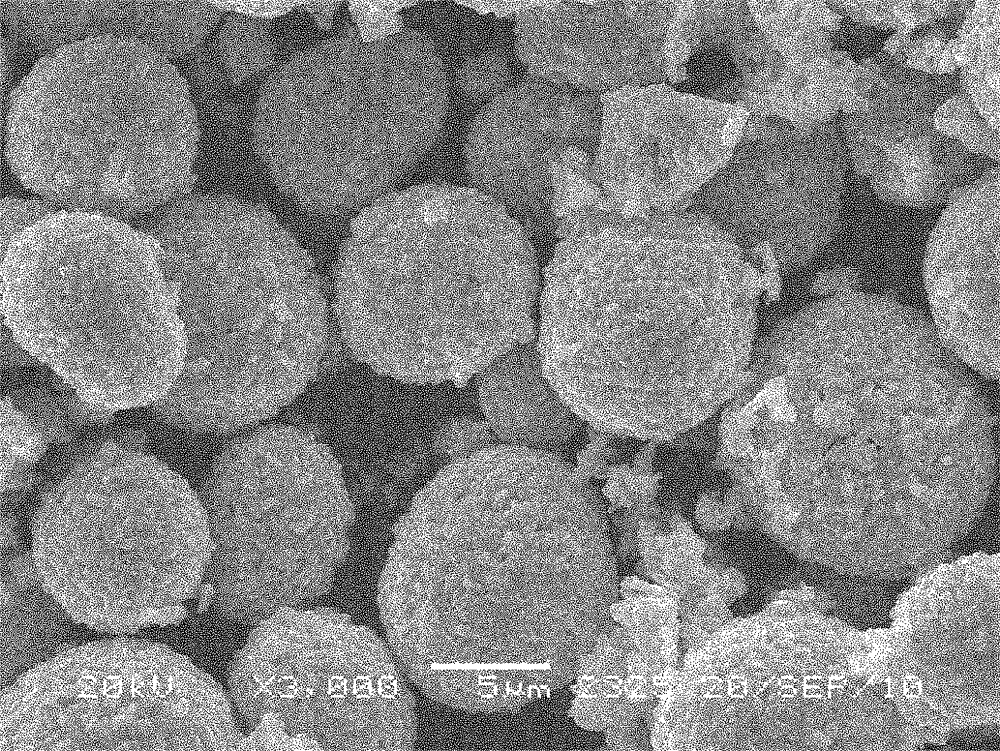

[0039] First, nickel sulfate, cobalt sulfate and aluminum sulfate are mixed in molar ratio Ni 2+ :Co 2+ : Al 3+ =0.75: 0.2: 0.05 is mixed and formulated into 2mol / L aqueous solution, ammonium persulfate is formulated into 3mol / L aqueous solution, lithium hydroxide is formulated into 5mol / L solution 2L and adds 0.5L 1.5mol / L ammoniacal liquor. Then, the prepared mixed salt solution and ammonium persulfate solution are all fed into a 12L reaction kettle with a stirring device at a flow rate of 10ml / min, stirred at a speed of 550rpm and heated to 50°C to adjust the feed of the alkali solution The speed is to control the pH value of the reaction system between 10.5-11, and the reaction ends after 8 hours, and then the spherical nickel-cobalt-aluminum oxyhydroxide precursor is filtered out. Then, the spherical nickel-cobalt-aluminum oxyhydroxide was washed and filtered with deionized water for 6 times, and dried in a vacuum oven at 120° C. for 12 hours to obtain a precursor. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com