Paper dye sensitization solar battery photo-anode and preparation method thereof

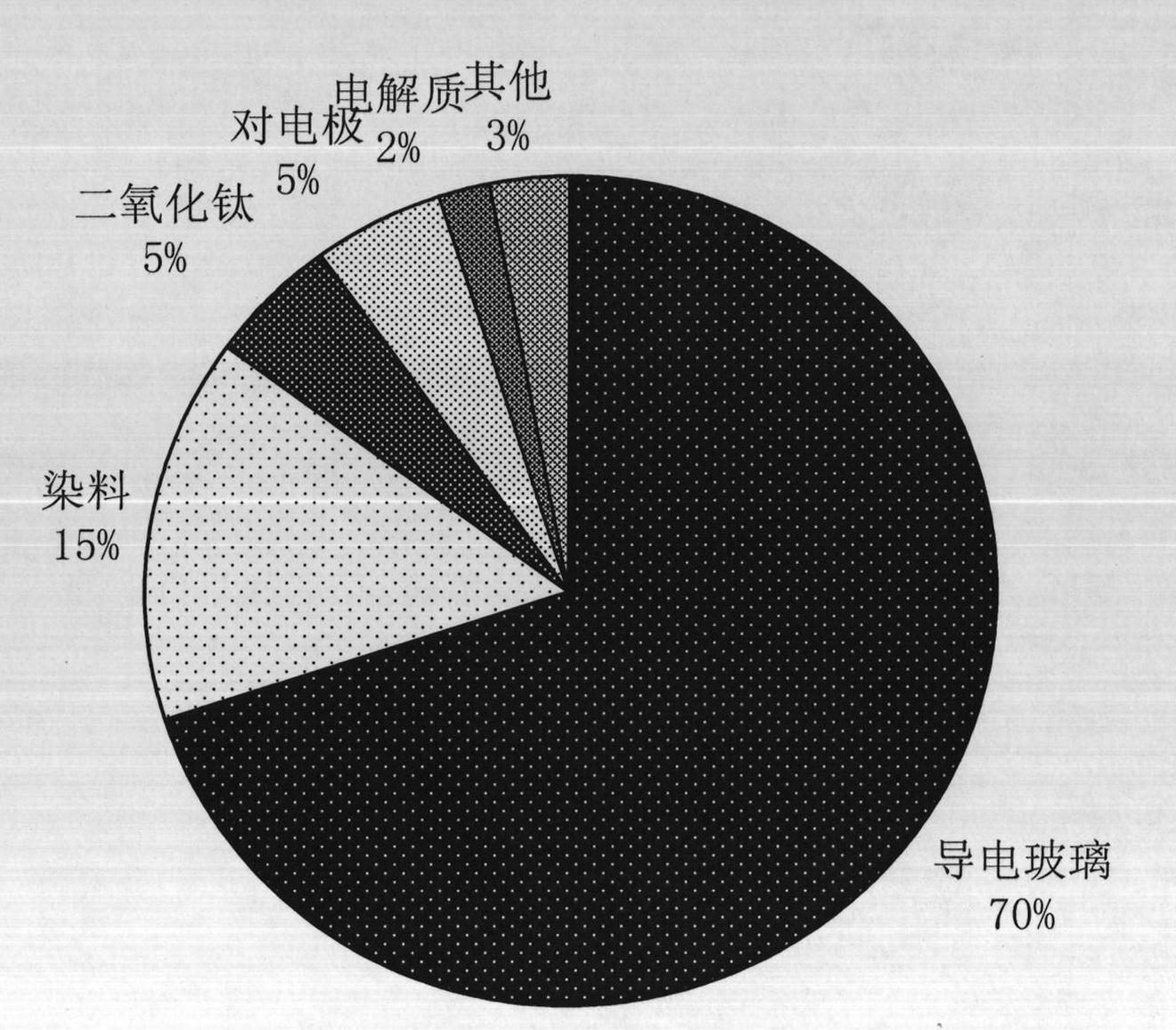

A solar cell and dye sensitization technology, applied in the field of paper-type dye-sensitized solar cell photoanode and its preparation, can solve the problems of hindering the large-scale industrial application of dye-sensitized solar cells, high manufacturing cost, complicated manufacturing process and the like , to achieve the effect of reasonable structure design, low cost and good light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the dye-sensitized solar cell in the embodiment: immerse the sintered nano-semiconductor film electrode in the ethanol solution of N719 dye for 12 hours, take it out, rinse it with absolute ethanol and dry it to make a dye-sensitized film Electrode; the prepared sensitizing electrode is used as the working electrode, the platinum-plated conductive substrate is used as the counter electrode, and the sensitized electrode containing 0.5M LiI, 0.05M I 2 and 0.5M acetonitrile solution of tetra-tert-butylpyridine as electrolyte to assemble a dye-sensitized solar cell with a "sandwich" structure.

[0049] The photoelectric test method of the dye-sensitized solar cell in the embodiment: the photoelectric performance measurement of the cell was measured at room temperature using a computer-controlled Oriel sunlight simulation system. The incident light intensity is 100mW / cm 2 , the illuminated area is 0.16cm 2 .

Embodiment 1

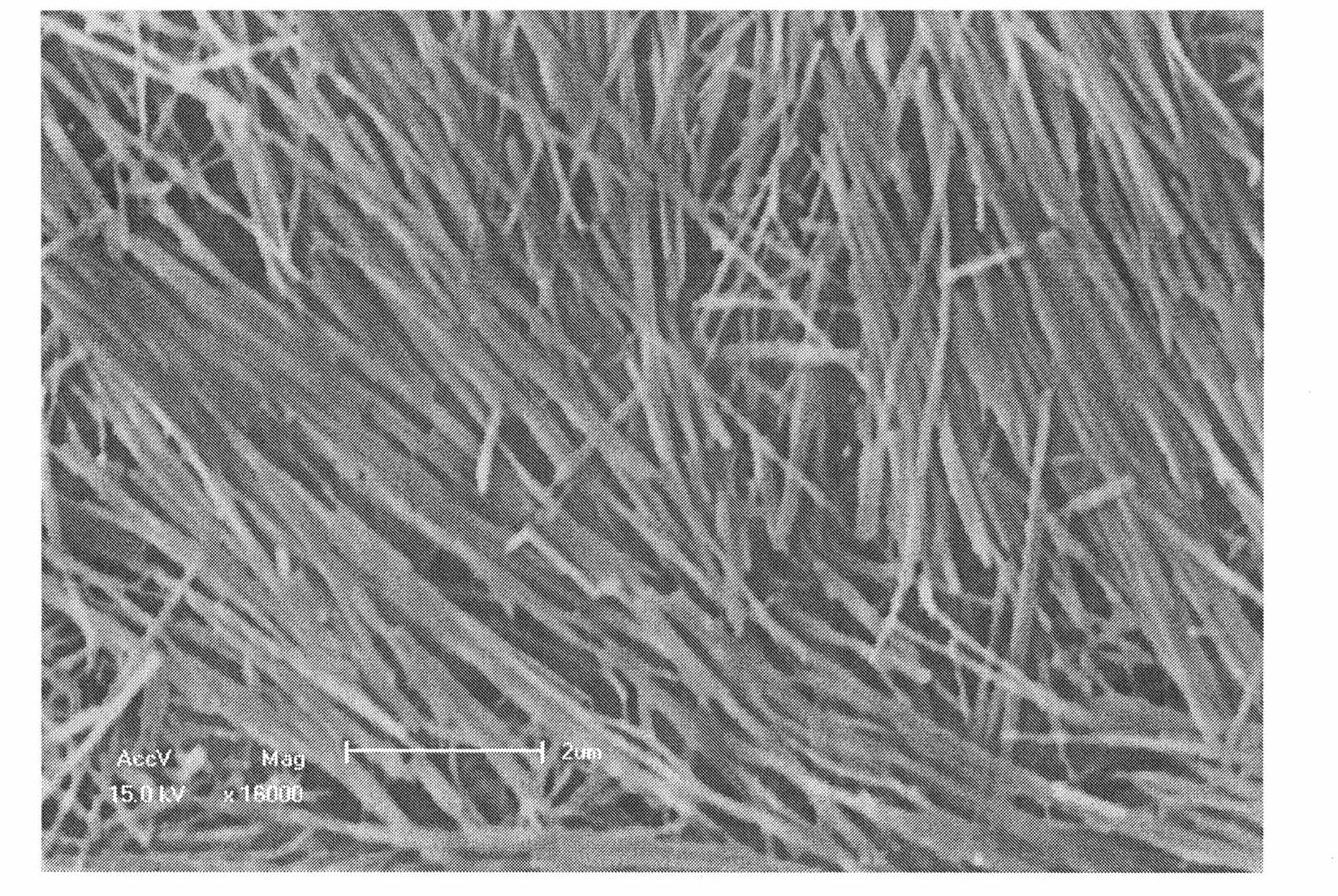

[0051] (1) Nanofibers were synthesized by hydrothermal method: raw materials were 0.2g P25 powder + 30ml deionized water + 12gNaOH, hydrothermal reaction at 200°C for 96h;

[0052] (2) Add surfactant F-127 to the nanofiber slurry again, the mass fraction of surfactant F-127 is 0.1%, improve the dispersion performance of nanofibers in the slurry, and stir and mix to form a well-dispersed Nanofiber precursor slurry;

[0053] (3) the precursor slurry prepared by step (2) is made into nano-paper by hot pressing film-forming method;

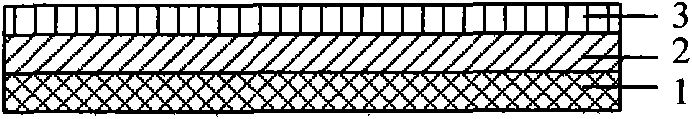

[0054] (4) Sintering the nano paper under the conditions of 200°C for 2h, 500°C for 30min, 500°C for 2h, and 600°C for 2h, then naturally cooling to room temperature, the thickness of the obtained nanopaper is 10 μm;

[0055] (5) Scrape-coat a layer of titanium dioxide slurry containing a binder such as terpineol and ethyl cellulose or an organic polymer pore-forming agent on the surface of the nano-paper after sintering and cooling, and sinter at 50...

Embodiment 2

[0060] The raw materials for hydrothermal synthesis are (0.25g Al 2 o 3 +30ml deionized water+12g NaOH), (0.15gSiO 2 +30ml deionized water+12g NaOH), (0.38g SnO 2 +30ml deionized water+12g NaOH), (0.7g In 2 o 3 +30ml deionized water+12g NaOH), (0.67g Nb 2 o 5 +30ml deionized water+12gNaOH), the sintering time is 500° C. for 2h, the rest of the conditions are the same as in Example 1, and the photoelectric conversion efficiencies are respectively 4.82%, 3.52%, 3.81%, 2.65%, and 2.82%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com