Growth factor slow release microballoon and preparation method thereof

A technology for sustained-release microsphere preparations and growth factors, which is used in pharmaceutical formulations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc. problem, to achieve the effect of good histocompatibility, prolonged physiological activity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

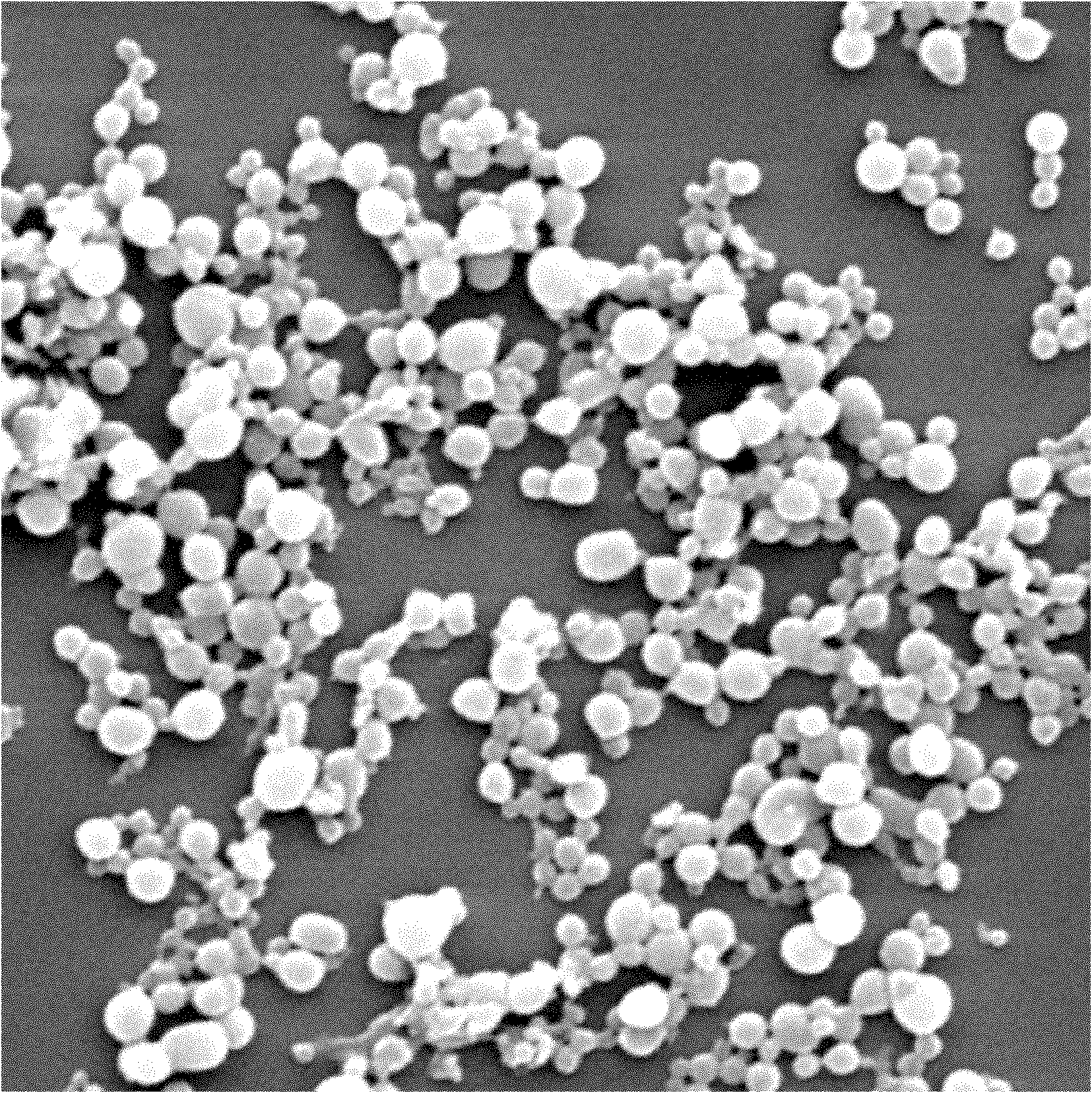

[0047] Example 1 Preparation of Growth Factor Slow-release Microspheres

[0048] Weigh 5 μg of nerve growth factor drug and dissolve it in 0.5 g of phosphate buffer, and use it as the water phase after it is completely dissolved; weigh 150 mg of monomethoxypolyethylene glycol polylactic acid (the molecular weight of polyethylene glycol is 5000, poly The polymerization ratio of ethylene glycol and polylactic acid is 1:100) dissolved in 5 g of organic solvent (dichloromethane: acetone = 6: 2) as the oil phase; mix the above water phase and oil phase, and ultrasonically disperse for 1 min to prepare an emulsion. . Add the above emulsion slowly to 20g of phosphate buffer (200mg of sodium alginate in the phosphate buffer), ultrasonically disperse for 1min, and continue to stir at room temperature at low speed for 3h, and remove the organic solvent to obtain the colloidal solution of growth factor microspheres.

Embodiment 2

[0049] Example 2 Preparation of Growth Factor Slow-release Microspheres

[0050] Weigh 10 μg of nerve growth factor drug and dissolve it in 1 g of phosphate buffer, and use it as the water phase after it is completely dissolved; weigh 300 mg of monomethoxypolyethylene glycol polylactic acid (the molecular weight of polyethylene glycol is 5000, polyethylene glycol The polymerization ratio of diol and polylactic acid (1:80) was dissolved in 10 g of organic solvent (dichloromethane: acetone = 6:2) as the oil phase; the above water phase and oil phase were mixed, ultrasonically dispersed for 1 min to prepare an emulsion, and set aside. Slowly add the above emulsion to 40g of phosphate buffer (containing 400mg of sodium alginate in the phosphate buffer), ultrasonically disperse for 1min, and continue stirring at room temperature at low speed for 5h, and remove the organic solvent to obtain the colloidal solution of growth factor microspheres.

Embodiment 3

[0051] Example 3 Preparation of Growth Factor Slow-release Microspheres

[0052] Weigh 20 μg of nerve growth factor drug and dissolve it in 2 g of phosphate buffer, and use it as the water phase after it is completely dissolved; weigh 600 mg of monomethoxypolyethylene glycol polylactic acid (the molecular weight of polyethylene glycol is 5000, polyethylene glycol The polymerization ratio of diol and polylactic acid is 1:120) dissolved in 20 g of organic solvent (dichloromethane: acetone = 6: 2) as the oil phase; the above water phase and oil phase were mixed, ultrasonically dispersed for 1 min to prepare an emulsion, and set aside. Slowly add the above emulsion to 80g of phosphate buffer (containing 800mg of sodium alginate in the phosphate buffer), ultrasonically disperse for 1min, and continue to stir at room temperature at low speed for 4h, and remove the organic solvent to obtain the colloidal solution of growth factor microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com