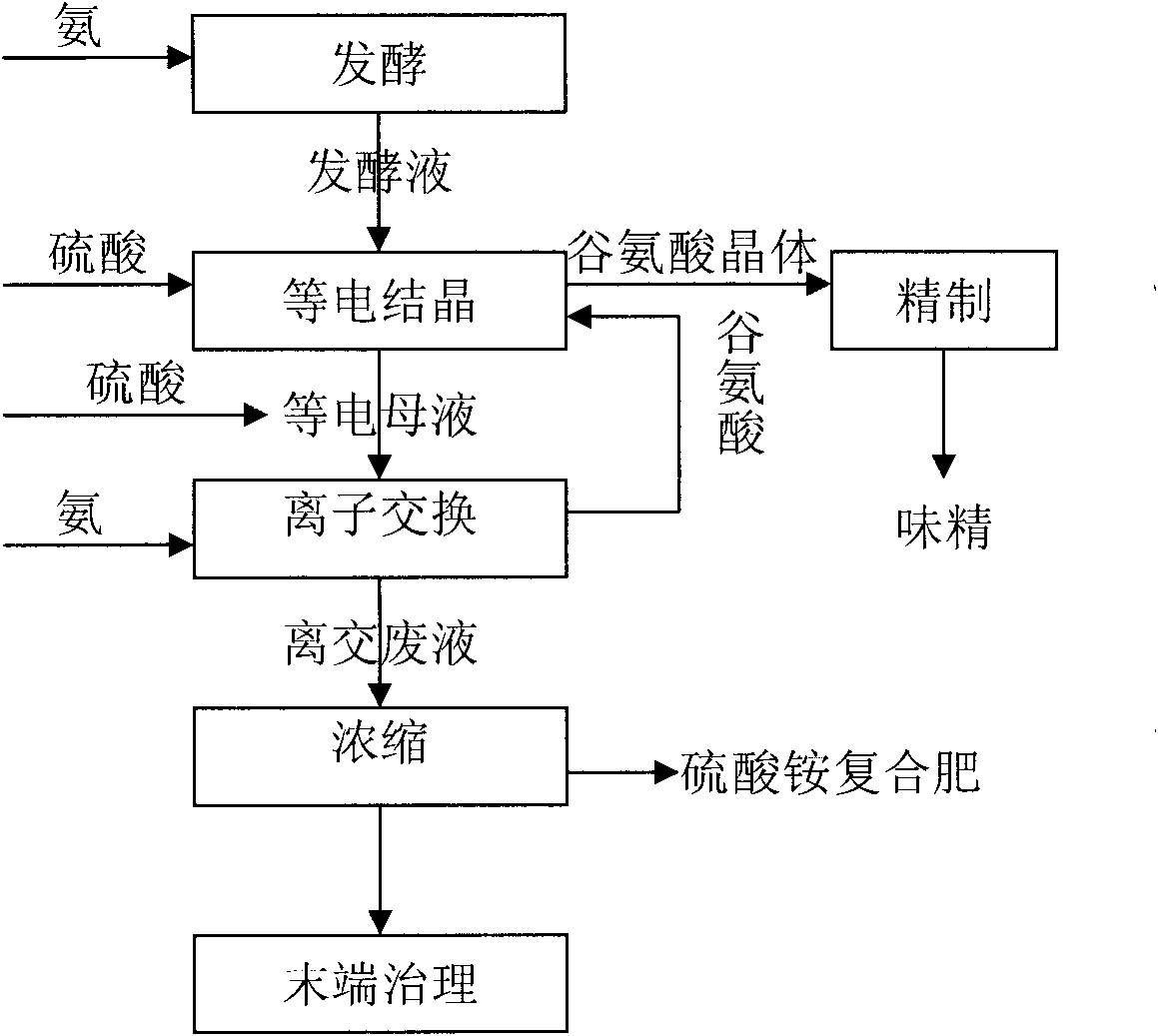

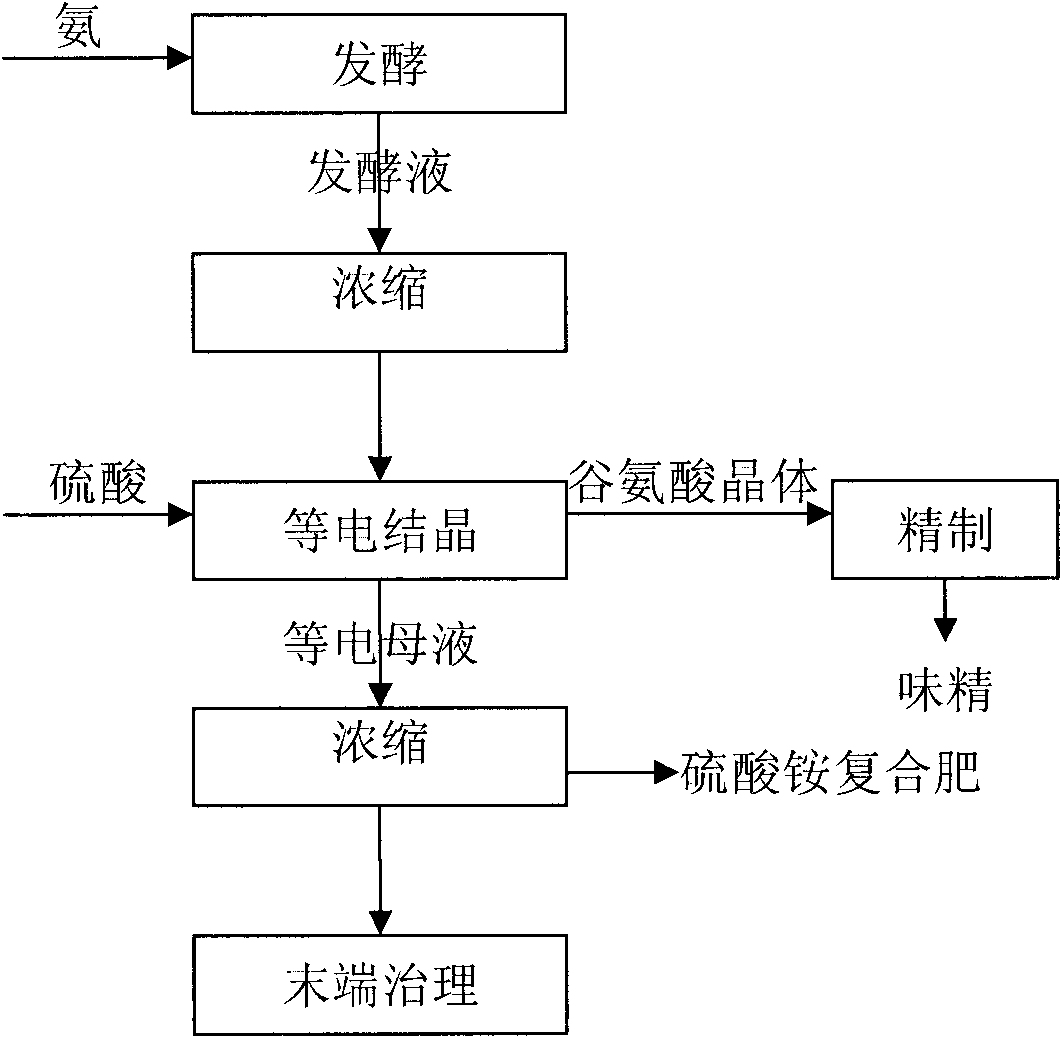

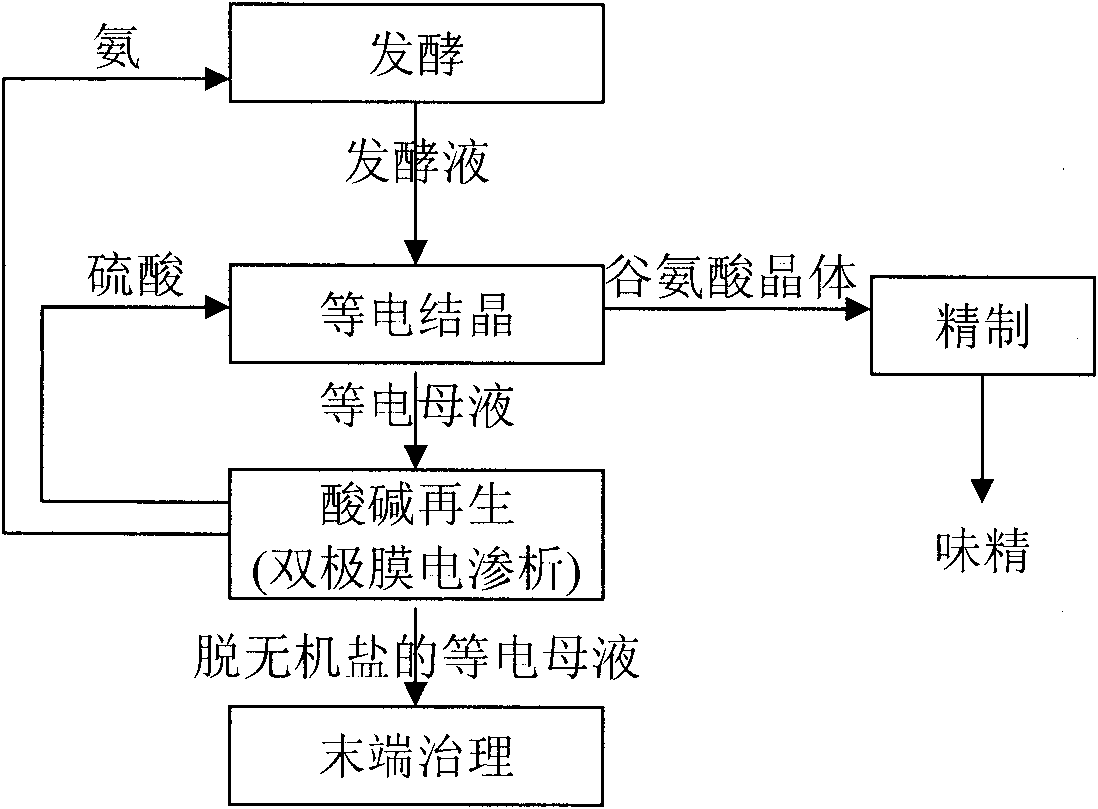

Method for treating isoelectric glutamic acid mother solution in monosodium glutamate production

A treatment method, glutamic acid technology, applied in the field of monosodium glutamate, can solve problems such as bipolar membrane electrodialysis hydrogen leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] The bipolar membrane electrodialyzer is a three-chamber bipolar membrane electrodialyzer with one stage and a single unit operating independently, and the liquid flow direction in adjacent compartments adopts co-current flow. The area of the ion exchange membrane is 210mm×62mm, using BP-1 bipolar membrane, JAM-10 anion exchange membrane and JCM-1 cation exchange membrane. The bipolar membrane, anion exchange membrane, and cation exchange membrane form a three-compartment membrane stack structure (such as Figure 5 ) Repeat 5 pairs. Use titanium coated ruthenium electrode as anode plate and stainless steel electrode as cathode plate. The partition and the screen are made of polypropylene material, the partition is a non-loop partition, and the partition is a woven mesh type.

[0093] See image 3 . Pass 4.8L of glutamic acid and other electrochemical mother liquor containing 42g / L ammonium sulfate and 18g / L glutamic acid from Shenyang Hongmei Monosodium Glutamate Factor...

Embodiment 2

[0096] The bipolar membrane electrodialysis device is the same as in Example 1.

[0097] Pass 4.8L of glutamic acid and other electrochemical mother liquor containing 34g / L of ammonium chloride and 17g / L of glutamic acid into the salt chamber; the initial liquid of the acid chamber is the filtrate of 1.0L glutamic acid fermentation broth, containing glutamic acid About 104g / L, the initial solution of the caustic chamber is 1L 0.05mol / L sodium hydroxide solution, and the two electrode chambers are both 1L 0.25mol / L sodium sulfate solution.

[0098] Control current density 30mA / cm during operation 2 , The linear velocity of liquid flow in each compartment is 3cm / s, and the temperature of material and liquid in each compartment is 30℃. Air is blown into the caustic chamber material cylinder, and the regenerated ammonia is blown out with air at a blowing rate of 1 liter / min. The ammonia blown from the alkali chamber is passed into a stainless steel coil placed in a refrigerator at -60...

Embodiment 3

[0100] The bipolar membrane electrodialysis device is the same as in Example 1.

[0101] Pass 4.8L of glutamic acid isoelectric mother liquor containing 51g / L of ammonium nitrate and 19g / L glutamic acid into the salt chamber; the initial liquid of the acid chamber is 1.0L glutamic acid fermentation broth, containing about 105g / L glutamic acid . The initial solution of the alkali chamber is 0.5L ammonia water with a mass concentration of 0.5%, and the two electrode chamber liquids are both 1L 0.25mol / L sodium sulfate solution.

[0102] Control current density 30mA / cm during operation 2 , The linear velocity of liquid flow in each compartment is 3cm / s, and the temperature of material and liquid in each compartment is 30℃. When the pH of the acid chamber drops to 4.2, the acid chamber appears turbid (glutamic acid crystals). At this time, continue the bipolar membrane electrodialysis operation, and connect the feed liquid inlet and outlet of a 1 liter hydrocyclone to the acid chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com