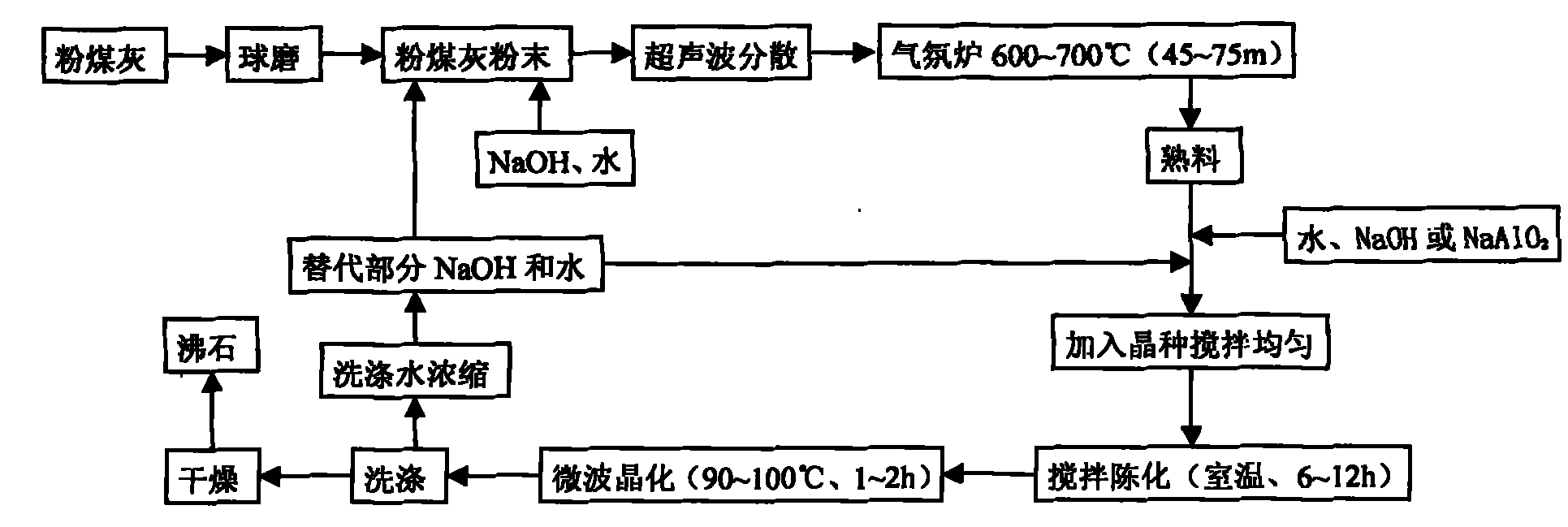

Method for synthesizing fly ash zeolite by alkali fusion-microwave process

A technology of fly ash zeolite and microwave method, which is applied in the direction of crystalline aluminosilicate zeolite, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of long time consumption, aging time, difficult reaction, etc., and achieve improvement Purity and conversion rate, reduction of formation of miscellaneous crystals, and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

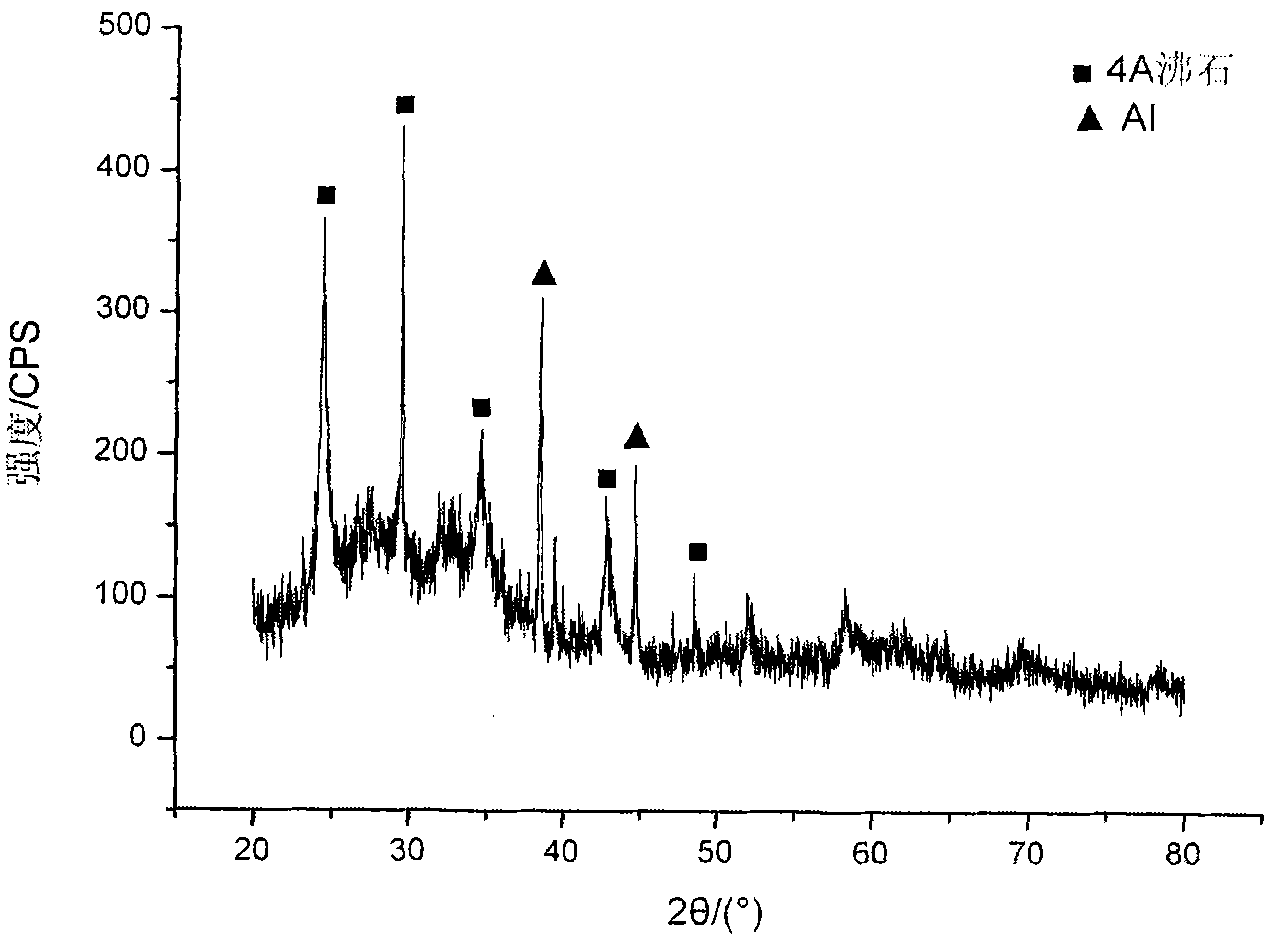

Embodiment 1

[0023] The fly ash was selected from Baotou Suburb No. 1 Thermal Power Plant, and its chemical composition is shown in Table 1.

[0024] (1) fly ash is carried out ball mill, and cross 200 mesh molecular sieves;

[0025] (2) take by weighing sodium hydroxide powder with the plastic container and mix by the mass ratio of 1.2: 1 with the fly ash after ball milling and sieving in step (1);

[0026] (3) Add water to the mixture of step (2), with a solid-to-liquid ratio of 1:1, ultrasonically disperse for 10 minutes, and then dry the resulting solid-water mixture at 100° C. for 1 hour;

[0027] (4) The mixture obtained in the step (3) is packed into a graphite crucible, feed nitrogen into the atmosphere furnace and roast at 600° C. for 45 minutes, and cool to room temperature with the furnace to obtain the alkali-melted fly ash clinker;

[0028] (5) After grinding the clinker obtained in step (4) to powder, weigh the clinker powder, add water according to the solid-liquid ratio of...

Embodiment 2

[0032] The fly ash was selected from Xi'an Baqiao Thermal Power Plant, and its chemical composition is shown in Table 2.

[0033] (1) fly ash is carried out ball mill, and cross 200 mesh molecular sieves;

[0034] (2) take by weighing sodium hydroxide powder with the plastic container and mix with the fly ash after ball milling and sieving in the step (1) by the mass ratio of 1.3:1;

[0035] (3) Add water to the mixture in step (2), the solid-to-liquid ratio is 1:3, ultrasonically disperse for 15 minutes, and then dry the resulting solid-water mixture at 100° C. for 2 hours;

[0036] (4) The mixture obtained in the step (3) is packed into a graphite crucible, and nitrogen gas is introduced into the atmosphere furnace and roasted at 650° C. for 60 minutes, and is cooled to room temperature with the furnace to obtain the alkali-melted fly ash clinker;

[0037] (5) After grinding the clinker obtained in step (4) to powder, weigh the clinker powder, add water according to the sol...

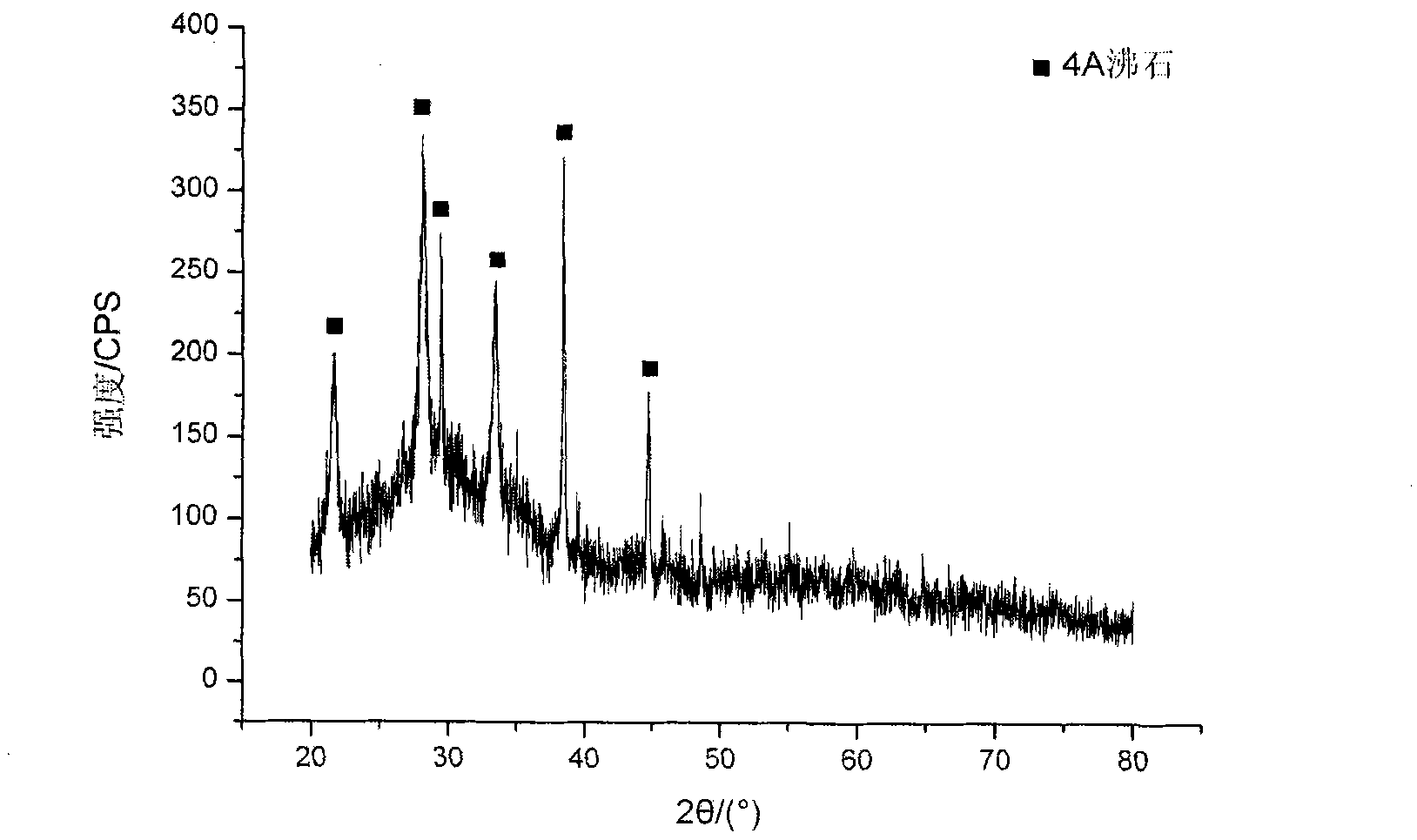

Embodiment 3

[0041] The fly ash was selected from Henan Luoyang Power Plant, and its chemical composition is shown in Table 3.

[0042] (1) fly ash is carried out ball mill, and cross 200 mesh molecular sieves;

[0043](2) take by weighing sodium hydroxide powder with the plastic container and mix with the fly ash after ball milling and sieving in the step (1) by the mass ratio of 1.4: 1;

[0044] (3) Add water to the mixture in step (2), the solid-to-liquid ratio is 1:5, ultrasonically disperse for 20 minutes, and then dry the resulting solid-water mixture at 100° C. for 1.5 hours;

[0045] (4) The mixture obtained in the step (3) is packed into a graphite crucible, and nitrogen gas is introduced into the atmosphere furnace and roasted at 700° C. for 75 minutes, and cooled to room temperature with the furnace to obtain the alkali-melted fly ash clinker;

[0046] (5) After grinding the clinker obtained in step (4) to powder, weigh the clinker powder, add water according to the solid-liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com