Sulfonated polyarylether polymer ion exchange membrane containing crosslinking groups and application thereof

A technology of ion exchange membrane and sulfonated polyarylether, which is applied in the application field of polymer ion exchange membrane in all-vanadium flow energy storage battery, can solve the problem of oxidation stability and other problems, and achieve good solubility and processing performance, good thermal and mechanical stability, and the effect of improving the selectivity of vanadium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

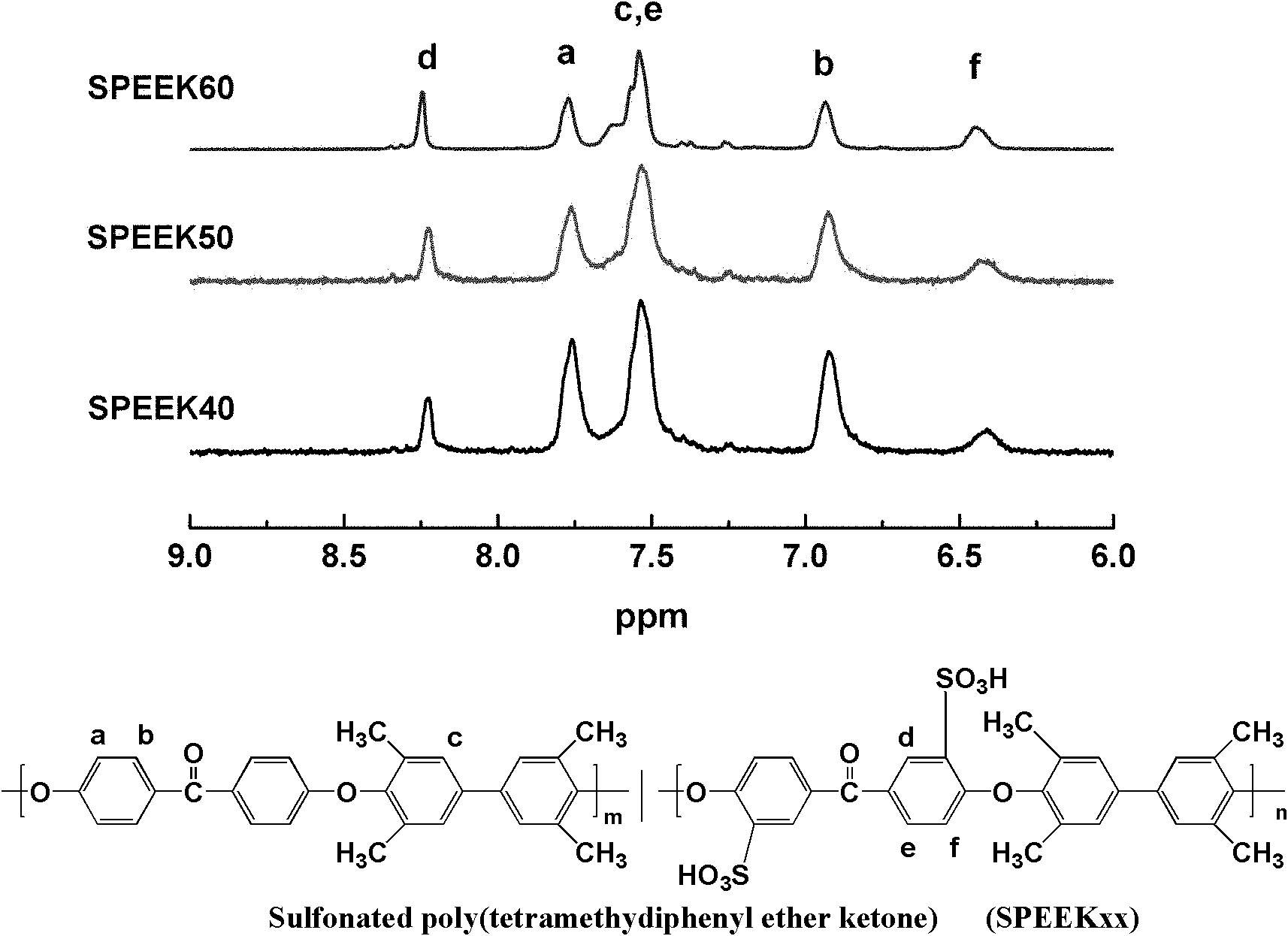

[0030] Add m mol of 1,4-bis(3-sulfonate sodium-4-fluoro-benzoyl)benzene, k mol of 4,4'-bis(4-fluoro-benzoyl)benzene, m+k mol of 3,3'4,4'-tetramethylbiquinone and m+k mol of anhydrous potassium carbonate were added to a three-necked flask equipped with mechanical stirring and a thermometer. Nitrogen protection, DMSO (NMP, TMS, DMAC can also be used) as a solvent (solid content 30wt%), toluene as a water-carrying agent, carry water at 140 ° C for 4 hours, then distill the toluene and heat up to 180 ° C to react 6 Hour. Pour the mixture into acetone, pulverize it in a 50wt% aqueous solution with a pulverizer, filter under reduced pressure, boil the obtained solid directly with acetone, reflux, and filter, repeat 5-6 times, then boil and filter with distilled water, repeat 5-6 times 6 times, dry in oven, obtain copolymer, productive rate is about 95%, (can adjust the sulfonation degree of polymkeric substance by adjusting the ratio of m and k, concrete sulfonation degree is as ta...

Embodiment 2

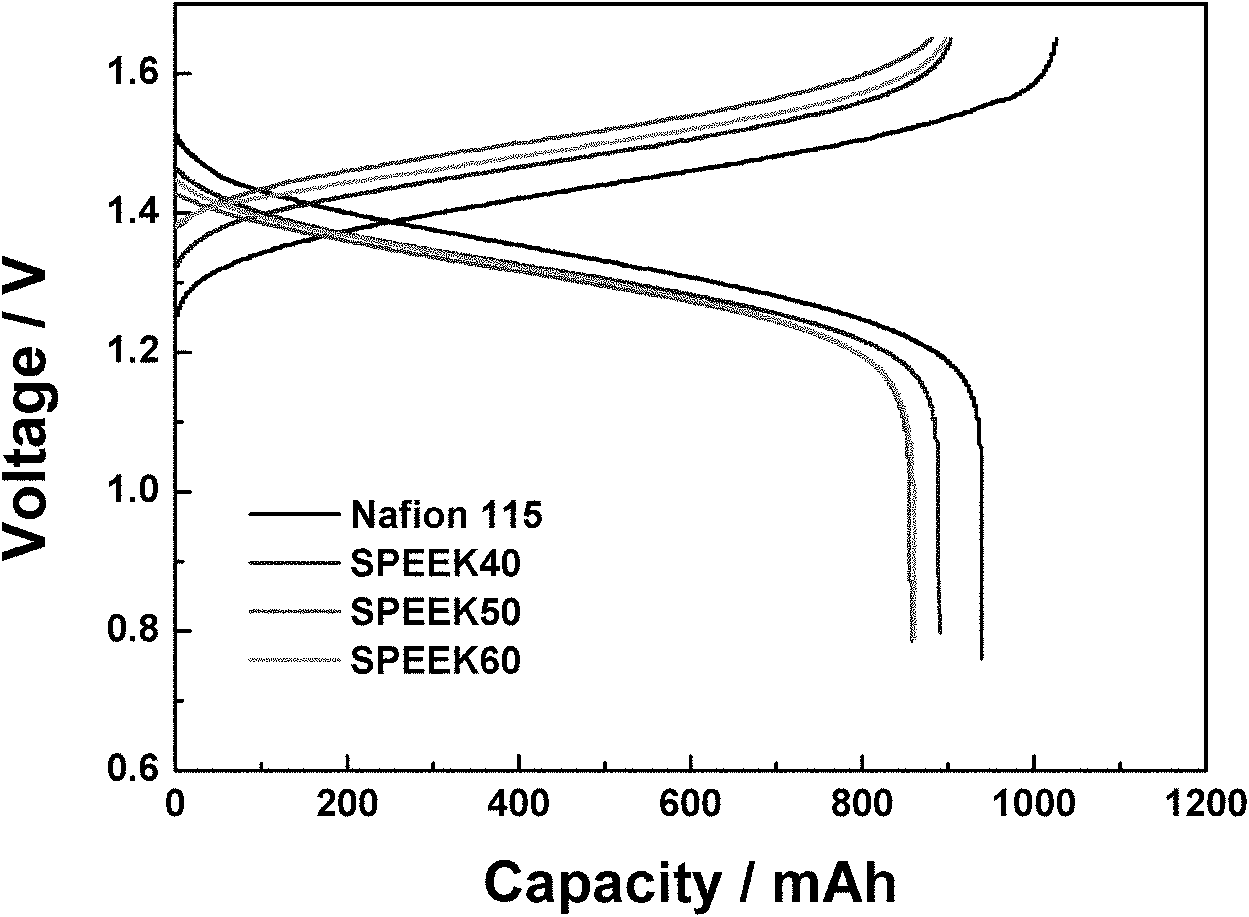

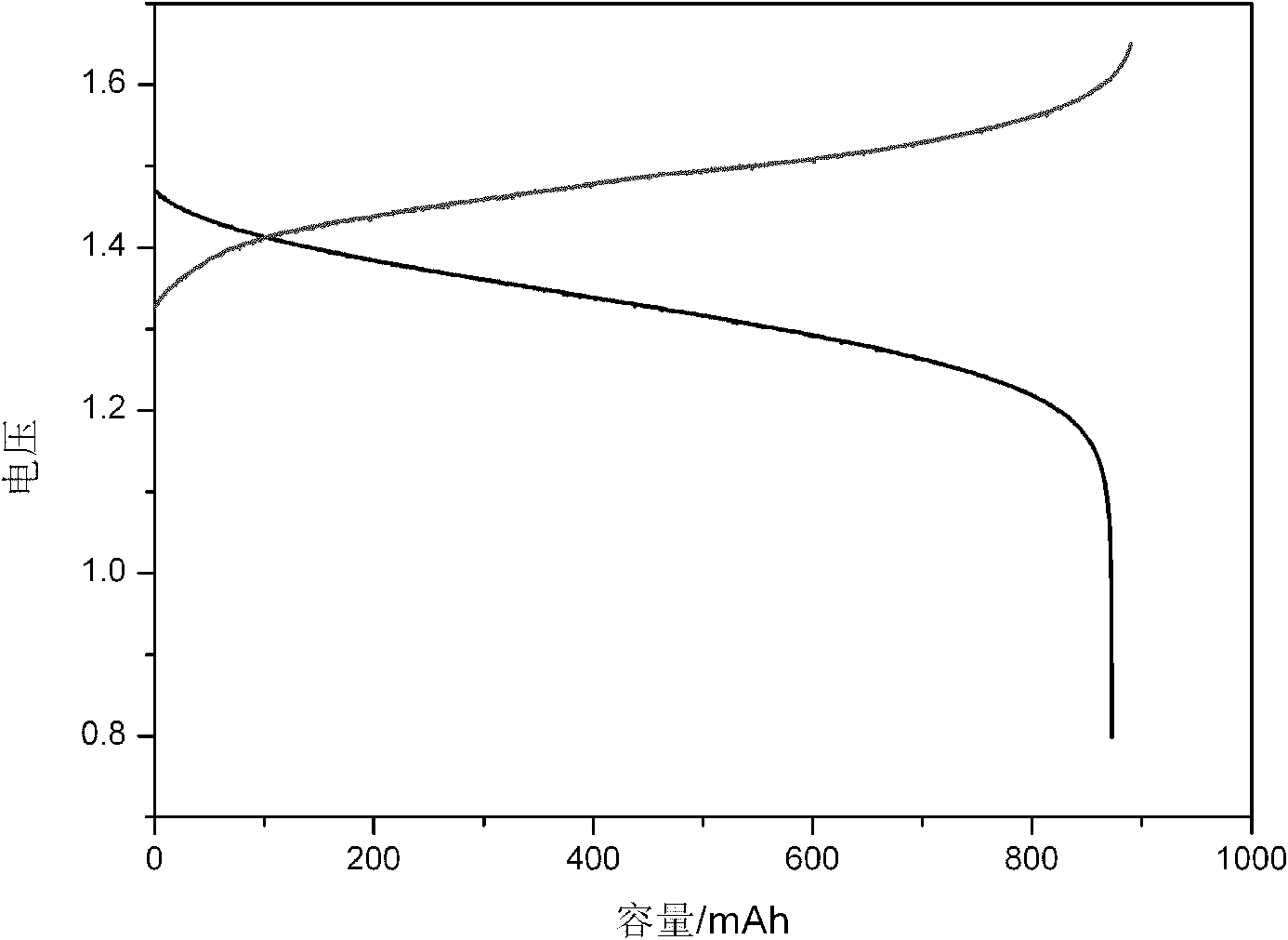

[0034] The polymer prepared in Example 1 was dissolved in DMF to form a 10wt% solution, and the resulting solution was cast on a glass plate or a stainless steel plate, dried at 60 for 5 hours, and then vacuum-dried at 80°C for 12 hours to form a film with a thickness of 90 μm about. Soak the prepared membrane in 1M sulfuric acid solution for 24 hours to obtain an ion exchange membrane. The prepared ion exchange membrane was assembled into an all-vanadium redox flow energy storage battery, the catalytic layer was activated carbon felt, the bipolar plate was graphite plate, and the effective area of the membrane was 9cm -2 , with a current density of 50mA cm -2 , the vanadium ion concentration in the electrolyte is 1.50mol L -1 , H 2 SO 4 The concentration is 3mol L -1 . In Example 1, the current efficiency of the ion exchange membrane assembled battery with the sulfonation degree of 0.8 is 98.5%, the voltage efficiency is 88.8%, and the energy efficiency is 87.5%. The...

Embodiment 3

[0036] Add m mol of 1,4-bis(3-sulfonate sodium-4-fluoro-benzoyl)benzene, k mol of 4,4'-bis(4-fluoro-benzoyl)benzene, m+k mol of allyl bisphenol A and m+k mol of anhydrous potassium carbonate were added to a three-necked flask equipped with mechanical stirring and a thermometer. Nitrogen protection, DMSO (NMP, TMS, DMAC can also be used) as a solvent (solid content 30wt%), toluene as a water-carrying agent, carry water at 140 ° C for 4 hours, then distill the toluene and heat up to 180 ° C for 6 hours . Pour the mixture into acetone, crush it in 50wt% aqueous solution with a pulverizer, filter under reduced pressure, boil the solid directly with acetone, reflux, and filter, repeat 5-6 times, then boil and filter with distilled water, repeat 5-6 times , drying in an oven to obtain a copolymer with a yield of about 95%, (the degree of sulfonation of the polymer can be adjusted by adjusting the ratio of m and k, the specific degree of sulfonation is shown in Table 2).

[0037] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com