Method and device for treating salt-containing wastewater produced during producing epoxy chloropropane by using glycerol as raw material

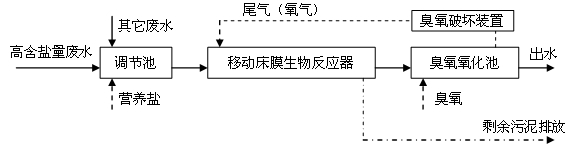

A technology of epichlorohydrin and salty wastewater, which is applied in the direction of oxidized water/sewage treatment, natural water treatment, water/sewage multi-stage treatment, etc., can solve the problems of difficult wastewater treatment, high treatment cost, and high treatment cost, and achieve Effective recycling and utilization, simple treatment process and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The mobile bed membrane bioreactor small-scale test device is used to treat the saline wastewater produced from glycerol as raw material for epichlorohydrin. The content of glycerol in the wastewater is 2500 mg / L, and the content of NaCl is 208000 mg / L; The effluent is mixed with the waste water at a ratio of 6-8:1. The COD of the effluent from the sewage treatment plant is 70-90 mg / L, the chloride ion concentration is 3000-5000 mg / L, and the COD of the mixed waste water is 500-700 mg / L. , the chloride ion concentration is about 20000-25000mg / L;

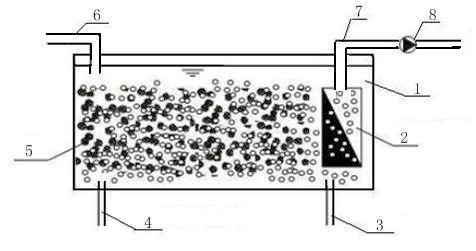

[0060] The moving bed membrane bioreactor small test device has an effective volume of 7.5L, and contains 60 PVC material columnar porous fillers with a diameter of 4cm and a height of 4cm. The filled fillers account for 50% of the effective volume of the reactor, and the reactor is equipped with 2 PVDF plates Type microfiltration membrane, the membrane pore size is 0.1-1 micron, and the effective area of the membrane is 0.0...

Embodiment 2

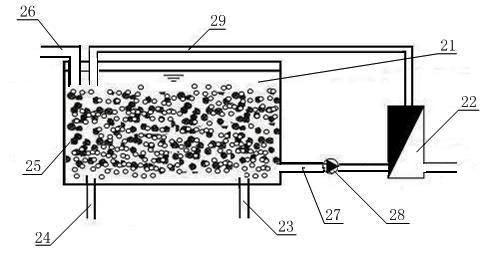

[0062] A membrane bioreactor with an effective volume of 400L is used to treat saline wastewater produced from epichlorohydrin using glycerol as a raw material. The pretreatment method is the same as in Example 1. The COD of the wastewater after mixing is 600-700mg / L, and the chloride ion concentration is about 17000~20000mg / L;

[0063]The reactor is equipped with a plate-type membrane module, the membrane material is the same as that of Example 1, and the effective area of the membrane is 1.3m 2 , the sludge concentration is 5000-6000mg / L, and the organic pollution load is 0.1 kgCOD / (kgMLSS day); after 60 days of stable operation, the COD of the reactor effluent can be controlled at 80-130 mg / L, see Image 6 The monitoring results of effluent COD and chloride ion concentration are shown in the figure.

Embodiment 3

[0065] The effluent treated in Example 2 was subjected to advanced treatment using the ozone oxidation step, and the ozonation reactor used in the experiment was a glass scrubber with an inner diameter of 10 cm, a height of 55 cm, and an effective volume of 4 liters. The mixed gas of oxygen and ozone generated by the ozone generator is continuously fed into the ozonation reactor, the air flow rate is 1L / min, and the ozone concentration is 60mg / L. After 20 minutes of ozonation reaction, the COD of the wastewater is changed from the initial 130mg / L was reduced to 90 mg / L, and the removal rate of total organic carbon could reach 45% after 60 minutes. The water quality treated by the ozone oxidation step meets the requirements of the secondary discharge standard of "Shanghai Municipal Standard Sewage Comprehensive Discharge Standard DB31 / 199-2009".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com