Preparation method of magnesium-silver co-doped zinc oxide nanocrystals

A technology of zinc oxide nano and nano crystals, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of low solid solubility of acceptor impurities, impossibility of doping, restriction of application, etc., and achieve defect peak Effect of weakening, narrow particle size distribution, improvement of zinc defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

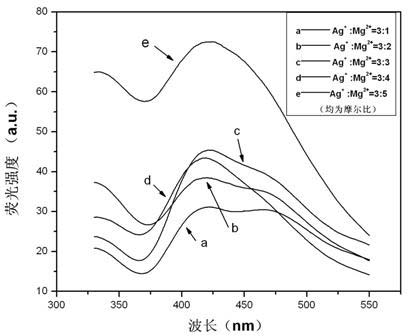

[0019] a. Put 18ml Triton X-100 (surfactant) into a small beaker, then add 75ml cyclohexane (continuous phase), 18ml n-hexanol (co-stabilizer) and 1ml water (discontinuous phase), Stir for 20 minutes to prepare a reverse microemulsion, then add 4ml, 0.25mol / L zinc nitrate solution, 120μL, 0.25mol / L silver nitrate solution, 40μL, 0.25mol / L magnesium nitrate solution, and stir for 30 minutes to obtain a microemulsion I.

[0020] b. Put 18ml of Triton X-100 (surfactant) into a small beaker, then add 75ml of cyclohexane (continuous phase), 18ml of n-hexanol (co-stabilizer) and 1ml of water (discontinuous phase), Stir for 20 minutes to prepare a reverse-phase microemulsion, then add 10ml, 1mol / L sodium hydroxide solution, stir for 30 minutes to obtain microemulsion II, mix and react microemulsion I and II for 12 hours to prepare Mg 2+ 、Ag + Co-doped [Zn(OH) 4 ] 2- Precursor;

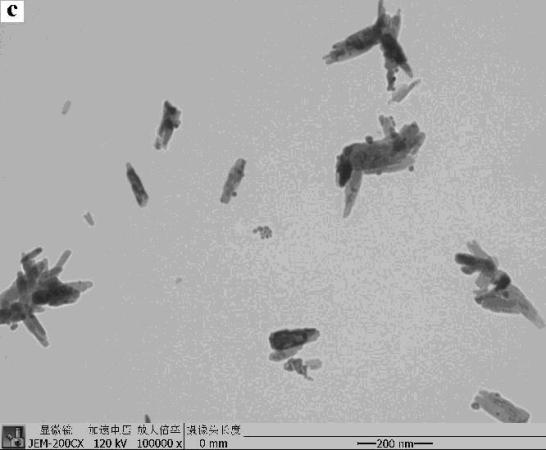

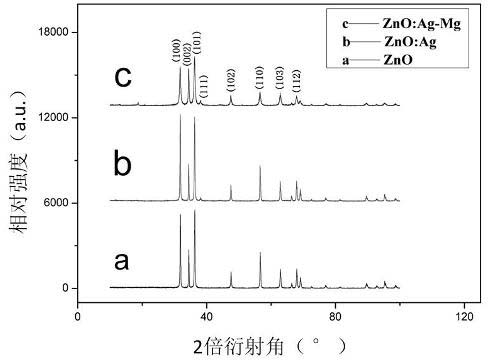

[0021] c. The above-prepared Mg 2+ 、Ag + Co-doped [Zn(OH) 4 ] 2- The precursor was hydrolyzed in ...

Embodiment 2

[0023] a. Take 18ml of Triton X-100 (surfactant) and put it in a small beaker, then add 75ml of cyclohexane (continuous phase), 18ml of n-hexanol (co-stabilizer) and 1ml of water (discontinuous phase), and stir for 20 Minutes, prepare reverse microemulsion, then add 4ml, 0.25mol / L zinc nitrate solution, 120μL, 0.25mol / L silver nitrate solution, 80μL, 0.25mol / L magnesium nitrate solution respectively, stir for 30 minutes to obtain microemulsion Ⅰ.

[0024] b. Take 18ml of Triton X-100 (surfactant) and put it in a small beaker, then add 75ml of cyclohexane (continuous phase), 18ml of n-hexanol (co-stabilizer) and 1ml of water (discontinuous phase), and stir for 20 Minutes, prepare reverse microemulsion, then add 10ml, 1mol / L sodium hydroxide solution, stir for 30 minutes, get microemulsion II, mix microemulsion I and II for 12 hours, make Mg 2+ 、Ag + Co-doped [Zn(OH) 4 ] 2- Precursor;

[0025] c. The above-prepared Mg 2+ 、Ag + Doped [Zn(OH) 4 ] 2- The precursor was hy...

Embodiment 3

[0027] a. Put 18ml Triton X-100 (surfactant) into a small beaker, then add 75ml cyclohexane (continuous phase), 18ml n-hexanol (co-stabilizer) and 1ml water (discontinuous phase), Stir for 20 minutes to prepare an inverse microemulsion, then add 4ml, 0.25mol / L zinc nitrate solution, 120μL, 0.25mol / L silver nitrate solution, 120μL, 0.25mol / L magnesium nitrate solution, and stir for 30 minutes to obtain a microemulsion I.

[0028] b. Put 18ml of Triton X-100 (surfactant) into a small beaker, then add 75ml of cyclohexane (continuous phase), 18ml of n-hexanol (co-stabilizer) and 1ml of water (discontinuous phase), Stir for 20 minutes to prepare a reverse-phase microemulsion, then add 10ml, 1mol / L sodium hydroxide solution, stir for 30 minutes to obtain microemulsion II, mix and react microemulsion I and II for 12 hours to prepare Mg 2+ 、Ag + Co-doped [Zn(OH) 4 ] 2- Precursor;

[0029] c. The above-prepared Mg 2+ 、Ag + Co-doped [Zn(OH) 4 ] 2- The precursor was hydrolyzed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com