Novel expansion-type charring agent for flame-retardant polyolefine material and synthesis method thereof

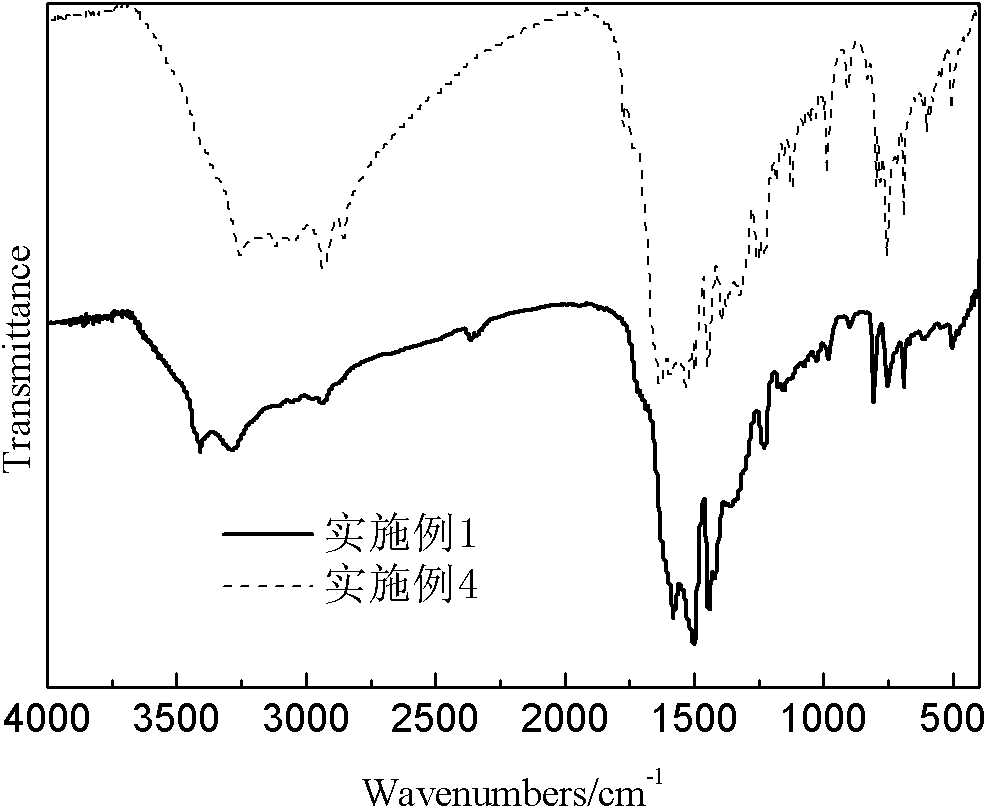

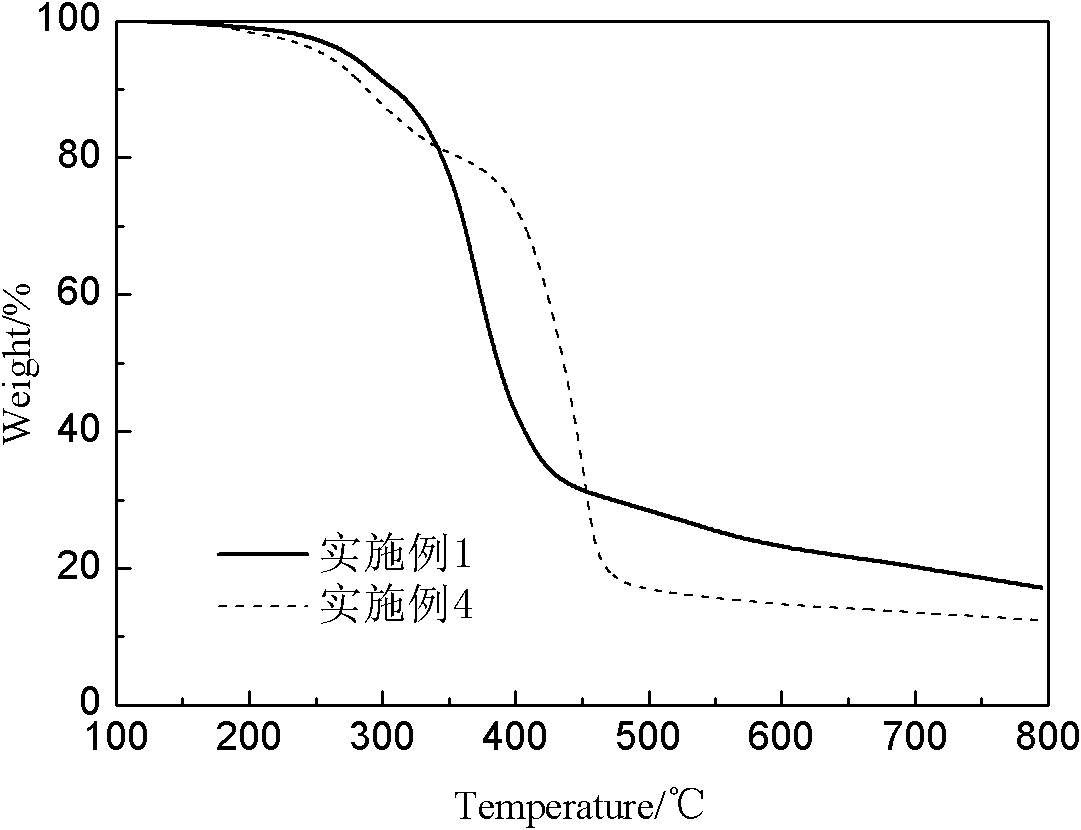

A synthesis method and expansion technology, applied in the field of expansion carbon forming agent and its synthesis, can solve the problems of large amount of organic solvent used, discontinuous reaction process, low carbon production of products, etc., and achieve good thermal stability, reaction The effect of continuous process and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

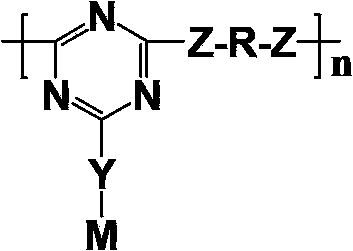

Method used

Image

Examples

Embodiment 1

[0034] Add 92.25g (0.5mol) of cyanuric chloride to a 1000ml four-necked flask equipped with a reflux condenser, thermometer, stirrer, and constant pressure dropping funnel, then add 200ml of acetone, and place the four-necked flask in an ice bath , stir well to make cyanuric chloride disperse evenly, add 46.56g (0.5mol) aniline dropwise to the four-necked bottle, dissolve 20g (0.5mol) sodium hydroxide in 50ml distilled water, add dropwise with a constant pressure funnel, and control the pH In 5-7, the reaction temperature is controlled at 0-10° C., and the reaction time is 1-2 hours to obtain a monosubstituted cyanuric chloride.

[0035] After the aniline is added dropwise, add 15.03g (0.25mol) of ethylenediamine dropwise to the four-necked bottle with a constant pressure funnel, dissolve 20g (0.5mol) of sodium hydroxide in 50ml of distilled water, and add dropwise to the In the four-necked bottle, the temperature is raised to 40-60°C, the dropping speed is controlled, the pH ...

Embodiment 2

[0038] In a 500ml four-necked bottle equipped with a reflux condenser, a thermometer, a stirrer, and a constant pressure dropping funnel, add 46.13g (0.25mol) of cyanuric chloride, then add 80ml of acetone and 20ml of distilled water, and place the four-necked bottle in In an ice bath, stir well to disperse cyanuric chloride evenly, add dropwise 23.53g (0.25mol) of phenol into the four-necked bottle, dissolve 10g (0.25mol) of sodium hydroxide in 25ml of distilled water, and dropwise add , the pH is controlled at 5-7, the reaction temperature is controlled at 0-10°C, and the reaction time is 1-3 hours to obtain a monosubstituted cyanuric chloride.

[0039] After the aniline is added dropwise, add 7.51g (0.125mol) of ethylenediamine dropwise to the four-necked bottle with a constant pressure funnel, dissolve 10g (0.25mol) of sodium hydroxide in 20ml of distilled water, and add dropwise to the In the four-necked bottle, the temperature is raised to 40-60°C, the dropping speed is ...

Embodiment 3

[0042] Add 92.25g (0.5mol) of cyanuric chloride to a 1000ml four-necked flask equipped with a reflux condenser, thermometer, stirrer, and constant pressure dropping funnel, then add 200ml of acetone, and place the four-necked flask in an ice bath , stir well to make cyanuric chloride disperse evenly, add 46.56g (0.5mol) aniline dropwise to the four-necked bottle, dissolve 20g (0.5mol) sodium hydroxide in 50ml distilled water, add dropwise with a constant pressure funnel, and control the pH In 5-7, the reaction temperature is controlled at 0-5° C., and the reaction time is 1-2 hours to obtain a monosubstituted cyanuric chloride.

[0043] After the aniline is added dropwise, add 22.04g (0.25mol) of 1,4-butanediamine dropwise into the four-necked flask with a constant pressure funnel, dissolve 20g (0.5mol) of sodium hydroxide in 50ml of distilled water, and Add the funnel dropwise into the four-necked bottle, raise the temperature to 40-60°C, control the drop rate, keep the pH va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com