Preparation method of composite metallic oxide powder

A composite metal and oxide powder technology, applied in chemical instruments and methods, zirconia, manganese compounds, etc., can solve the problems of high cost of liquid phase method, high energy consumption of solid phase method, unfriendly environment, etc., and achieve sintering activity Good, inhibit excessive growth of crystal grains, high atom utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] To prepare 1 kg of LSM submicron powder, the specific preparation method is as follows:

[0029] (1) According to the stoichiometric ratio of the LSM chemical formula, the corresponding doses of lanthanum oxide, strontium carbonate and manganese acetate are added to the ball mill tank, a certain amount of deionized water is added, and ball milled for 5 hours to obtain a slurry;

[0030] (2) Weighing 0.1 kg of sucrose and dissolving it in deionized water, adding the solution to the slurry in step (1), and ball milling for 2 hours to make it evenly mixed;

[0031] (3) Move the slurry obtained after ball milling in step (2) into an oven, and dry at 120° C. for 7 hours;

[0032] (4) Put the dried product obtained in step (3) into an electric furnace and heat-treat at 750° C. to obtain a perovskite-type LSM powder.

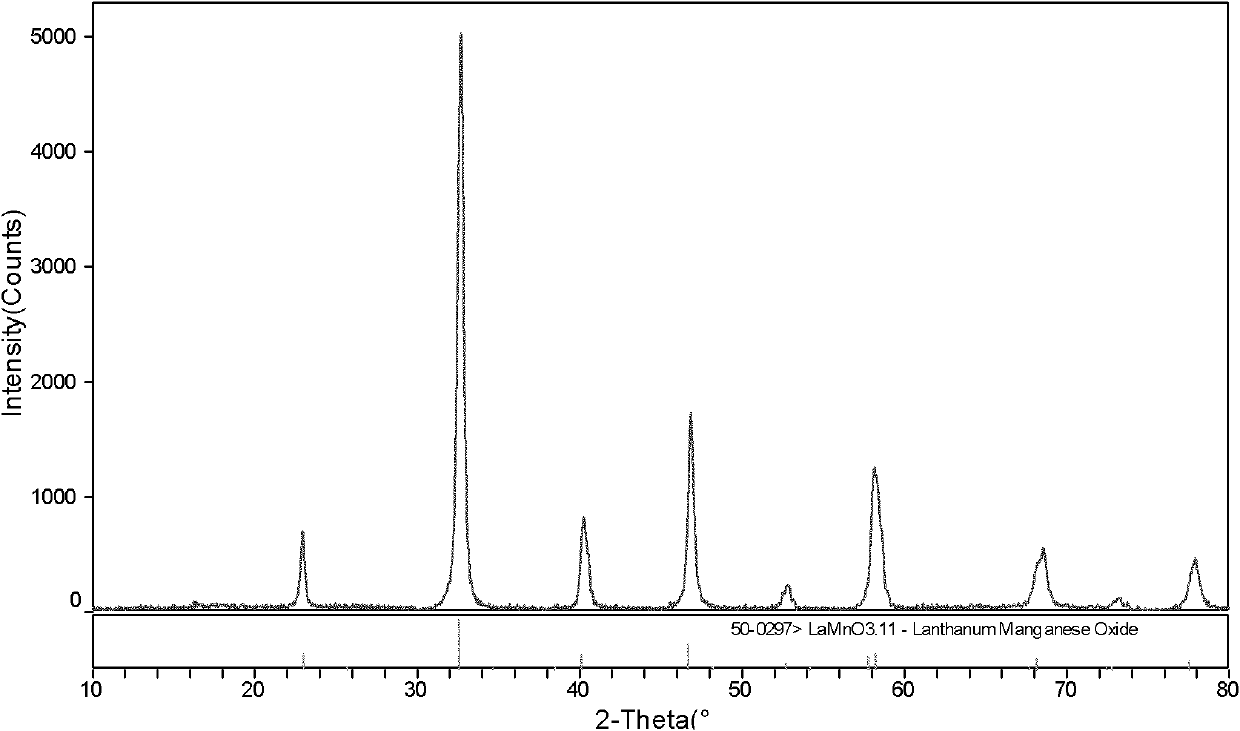

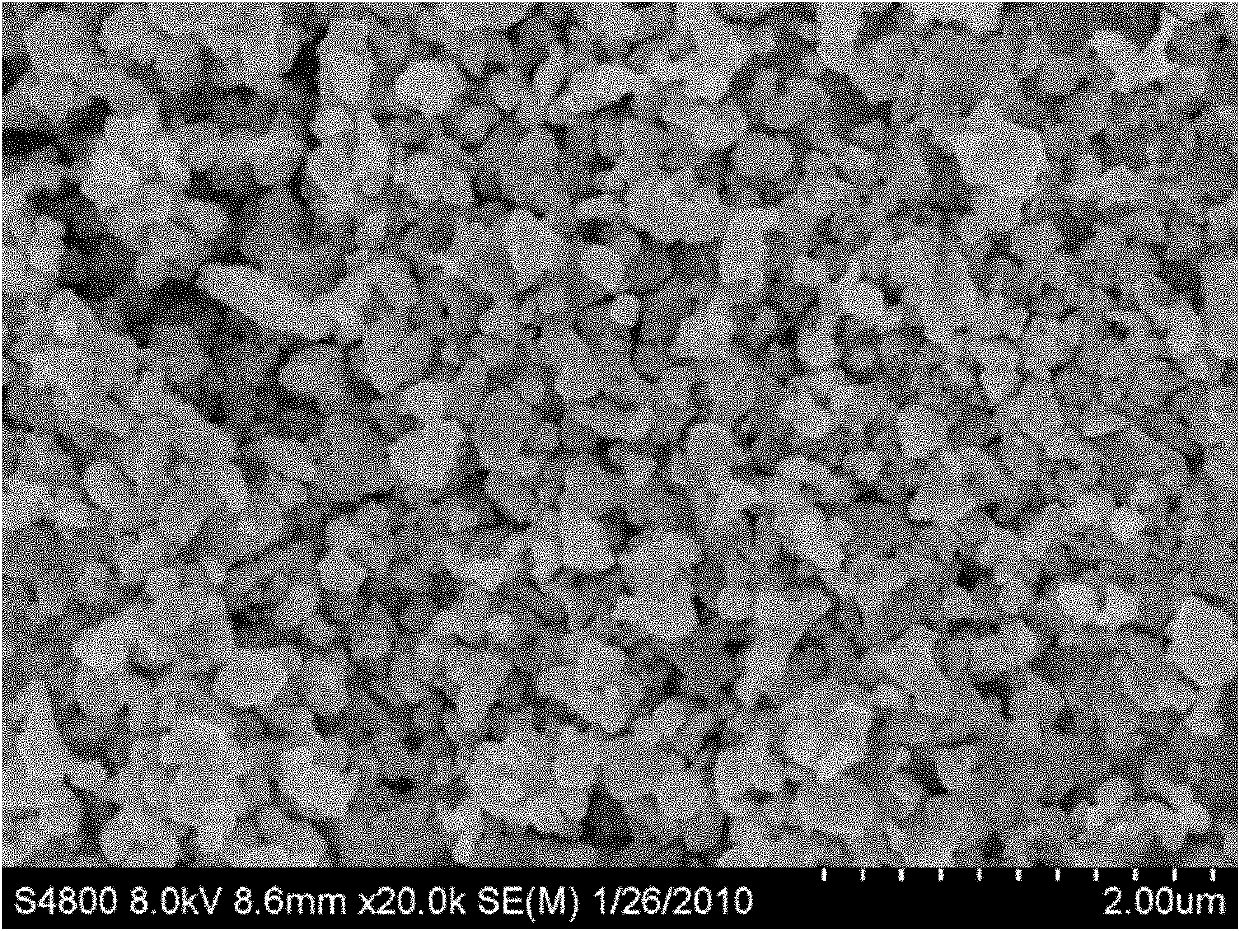

[0033] figure 1 It is the X-ray diffraction pattern of the perovskite-type LSM powder prepared by the above method. It can be seen from the figure that the LS...

Embodiment 2

[0035] Prepare 1 kg of YSZ submicron powder, the following is the specific preparation method:

[0036] (1) According to the stoichiometric ratio of the YSZ chemical formula, the corresponding doses of yttrium oxide and zirconia are added to the ball mill tank, a certain amount of deionized water is added, and ball milled for 6 hours to obtain a slurry;

[0037] (2) Weighing 0.4 kg of glucose and dissolving it in deionized water, adding the solution to the slurry in step (1), and ball milling for 3 hours to make it evenly mixed;

[0038] (3) Move the slurry obtained after ball milling in step (2) into an oven, and dry at 250° C. for 4 hours;

[0039] (4) Put the dried product obtained in step (3) into an electric furnace and heat-treat at 850° C. to obtain fluorite-type YSZ powder.

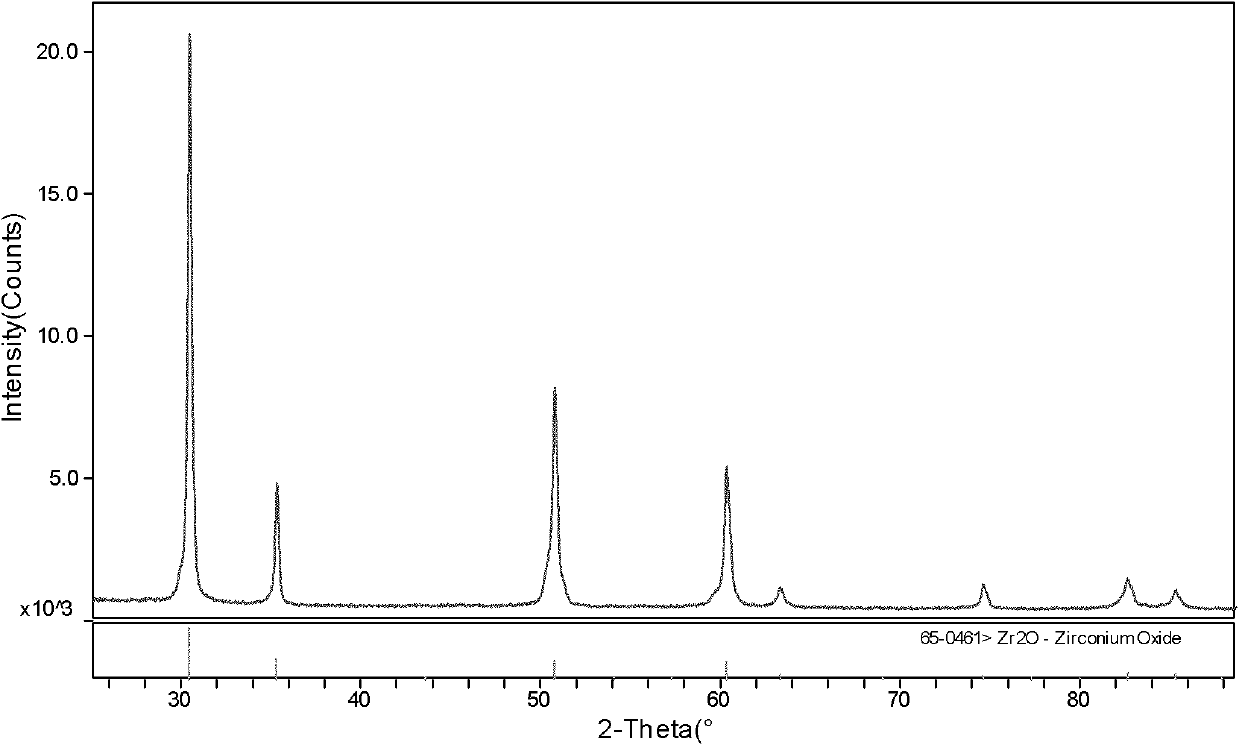

[0040] image 3 It is the X-ray diffraction spectrum of the fluorite-type YSZ powder prepared by the above method. It can be seen from the figure that the YSZ powder prepared by this method is a h...

Embodiment 3

[0042] To prepare 1 kg of LSC submicron powder, the specific preparation method is as follows:

[0043] (1) According to the stoichiometric ratio of the LSC chemical formula, add corresponding doses of lanthanum oxide, strontium acetate and cobalt oxide into the ball mill tank, add a certain amount of deionized water, and ball mill for 7 hours to obtain a slurry;

[0044] (2) Weighing 0.2 kilogram of citric acid is dissolved in deionized water, the solution is added in the slurry of step (1), and ball milled for 5 hours to make it evenly mixed;

[0045] (3) move the slurry obtained after ball milling in step (2) into an oven, and dry at 150° C. for 8 hours;

[0046] (4) Put the dried product obtained in step (3) into an electric furnace and heat-treat at 800° C. to obtain LSC powder with small particles, narrow particle size distribution range, and a particle size of 200 nm to 500 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com