Quality chemical sensor using functionalized mesoporous material as sensitive material and method

A technology of chemical sensors and mesoporous materials, applied in the field of micro-nano sensors, to achieve stable performance, low cost, and increase the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

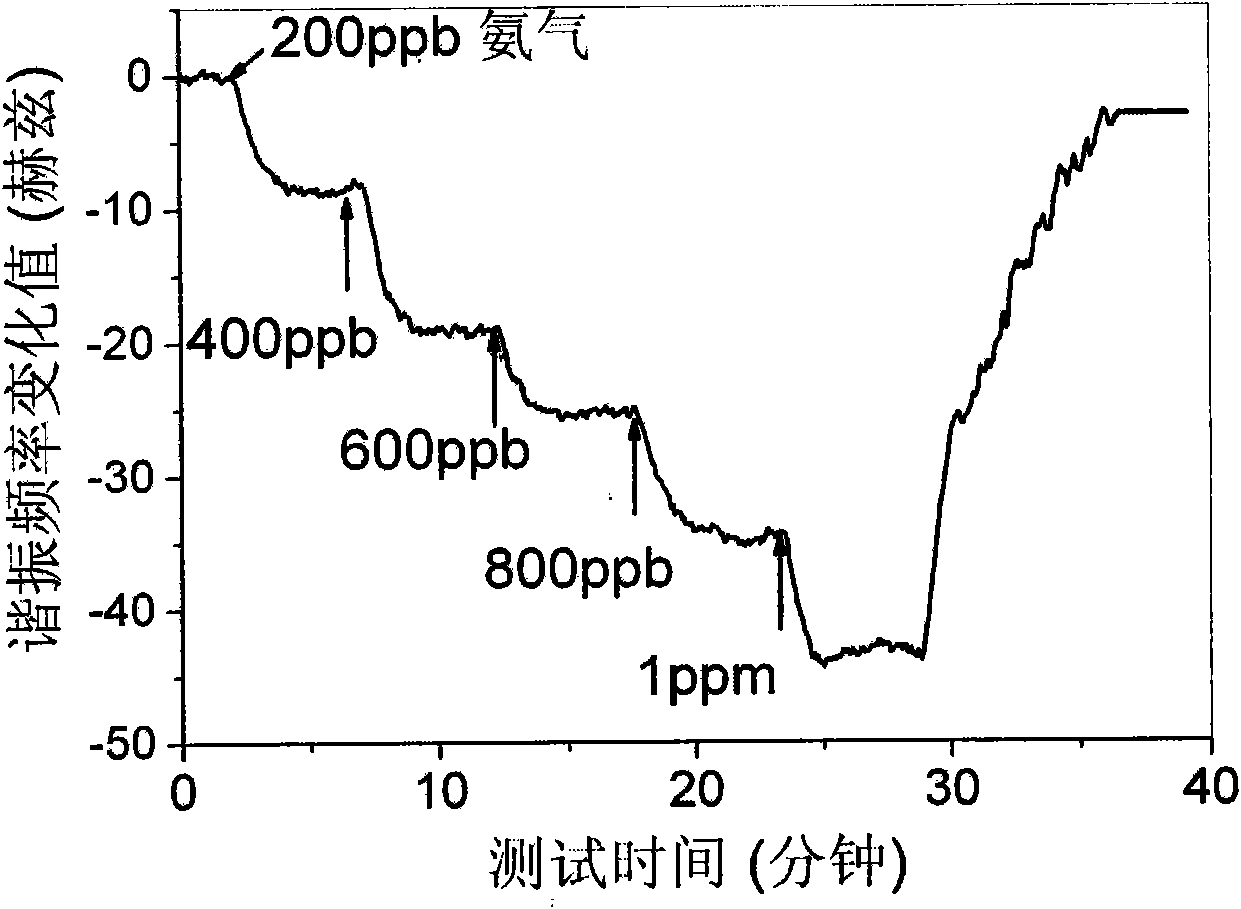

[0025] Example 1: Carboxyl-functionalized mesoporous silica powder is used as the sensitive material, and the resonant micro-cantilever beam is used as the transducer, which can be used for tens of ppb (ppb is the volume ratio is parts per billion) 1) A mass-based chemical sensor for magnitude-level ammonia gas detection.

[0026] ①The manufacturing method of carboxyl-functionalized mesoporous silica powder: Measure 1 milliliter of CES (carbomethoxysilanetriol, sodium salt, 25wt% in water, purchased from Germany ABCR Company) reagent, dissolve it in 30 milliliters of deionized water, and take the concentration of The concentrated hydrochloric acid of 36wt% adjusts the pH value of this solution to between 4-5, and this solution is placed in a volume and is 100 milliliters 2 mouth round bottom flasks, standby. Weigh about 0.2 g of SBA-15 type mesoporous silica material (pore diameter is about 7 nanometers, specific surface area is about 700 square meters per gram), add it into t...

Embodiment 2

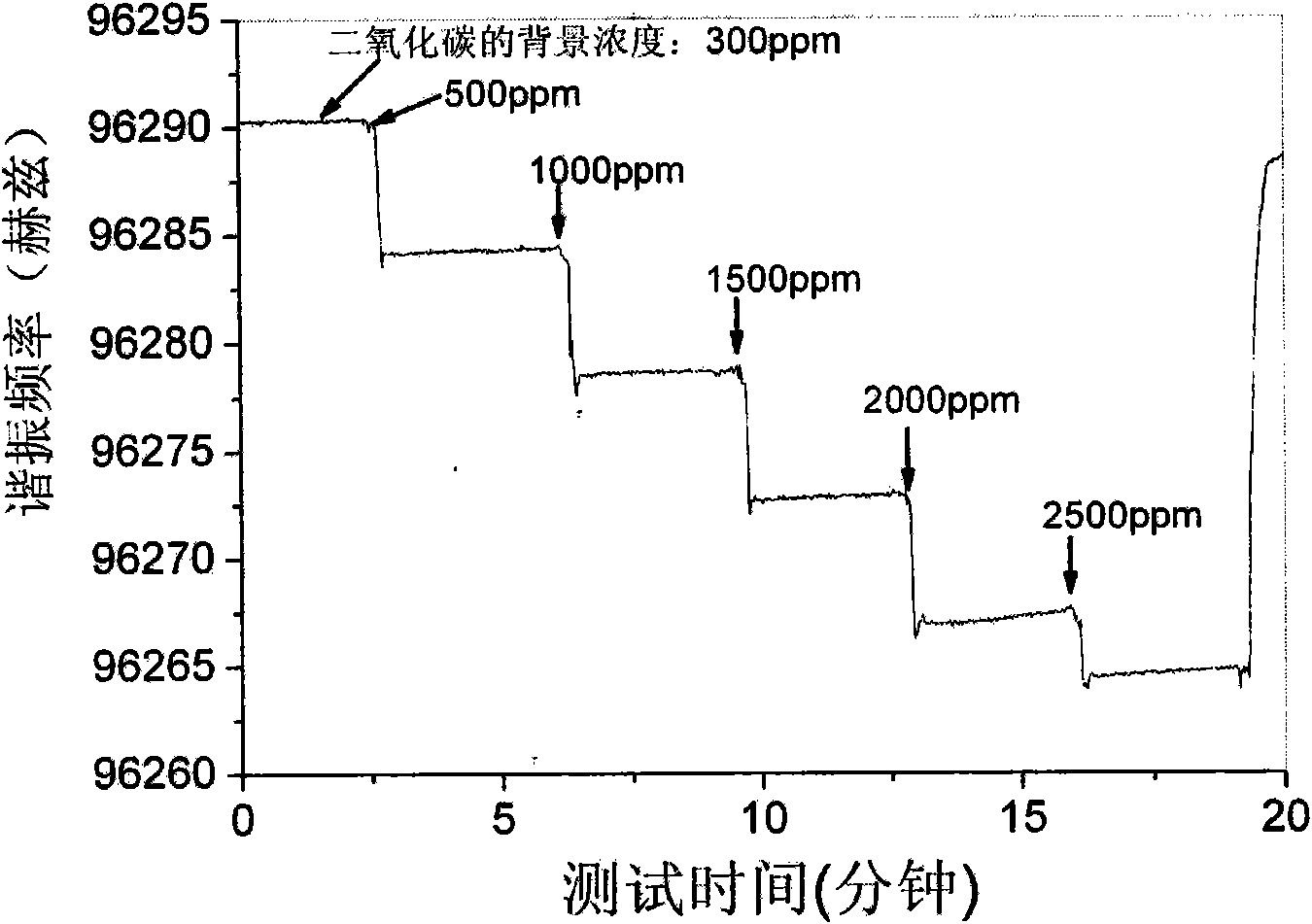

[0029] Example 2: Using the amine-based functionalized mesoporous film as the sensitive material and the resonant micro-cantilever beam as the transducer, the self-assembly method is used to manufacture tens of ppm (ppm is one millionth of the volume ratio) A mass chemical sensor for level carbon dioxide detection.

[0030]① A method of manufacturing mass-type carbon dioxide chemical sensors using amine-functionalized mesoporous films as sensitive materials and resonant micro-cantilever beams as transducers. The resonant micro-cantilever used in this embodiment is the same as that in Embodiment 1. The manufacturing method of the amine-functionalized mesoporous film is a one-step co-condensation method: Measure 41.2 ml of TEOS (tetraethylorthosilicate, analytically pure, purchased from Sinopharm Chemical Reagent Co., Ltd.), 40 ml of absolute ethanol, 1 microliter Concentrated hydrochloric acid with a concentration of 36 wt% and 4.2 ml of deionized water were added successively...

Embodiment 3

[0032] Example 3: Using mercapto-functionalized mesoporous silica powder as the sensitive material, and using quartz crystal microbalance (QCM) as the transducer, it is manufactured by coating method that can be used for hundreds of micrograms per liter (μg·L) -1 ) mass-type chemical sensor for heavy metal mercury ion detection.

[0033] A method for manufacturing a mass-type heavy metal ion chemical sensor with mercapto-functionalized mesoporous silica powder as a sensitive material and a QCM as a transducer. The QCM used in this embodiment has a resonant frequency of 10M (purchased from Beijing Chenjing Electronics Co., Ltd.). Weigh 10 mg of mercapto-functionalized mesoporous silica powder, and disperse it in 1 ml of deionized water by ultrasonic waves to prepare a suspension of mercapto-functionalized mesoporous silica. Use a precision micropipette (purchased from Gilson, France, with a specification of 0-20 microliters) to draw 20 microliters of the suspension and evenly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com