LED (Light-Emitting Diode) structure and manufacturing method thereof

A technology of LED structure and micro-nano structure, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of limited vertical structure LED application, low vertical structure LED yield, poor bonding process compatibility, etc., to improve light extraction. Efficiency, low price, effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: GaN-based blue LED chip with high-power vertical structure (or ordinary flip-chip structure) with periodic micro-nano structure on the transparent electrode surface

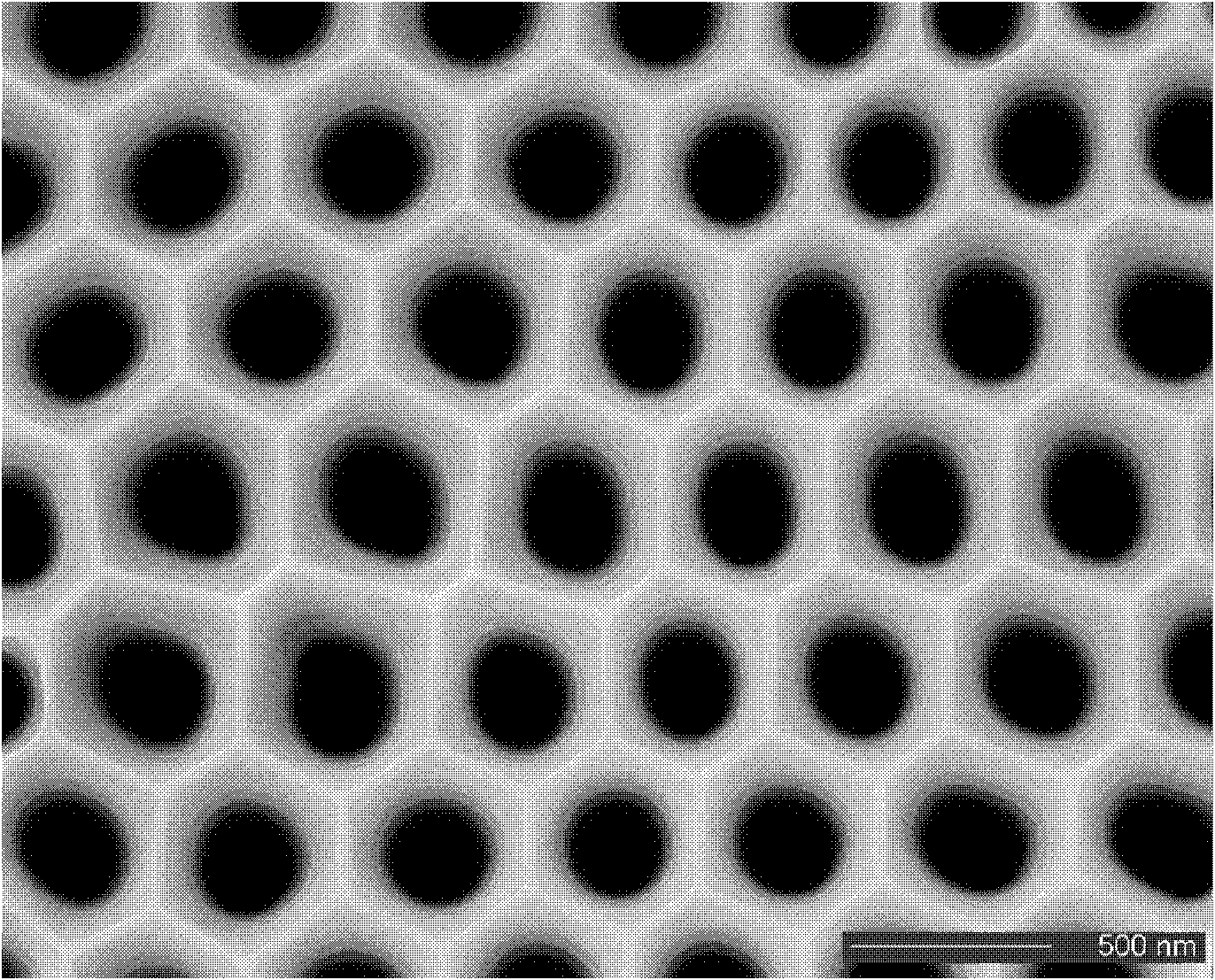

[0021] 1. Put the electropolished aluminum foil into a phosphoric acid solution, and prepare a periodic micro-nano-structured AAO film with a period of about 460 nm by secondary anodic oxidation. Remove the aluminum substrate with a saturated copper chloride solution, and then expand the pores with a 5% phosphoric acid solution to obtain a periodic micro-nano structure AAO template with a pore diameter of about 270 nm, such as figure 1 shown.

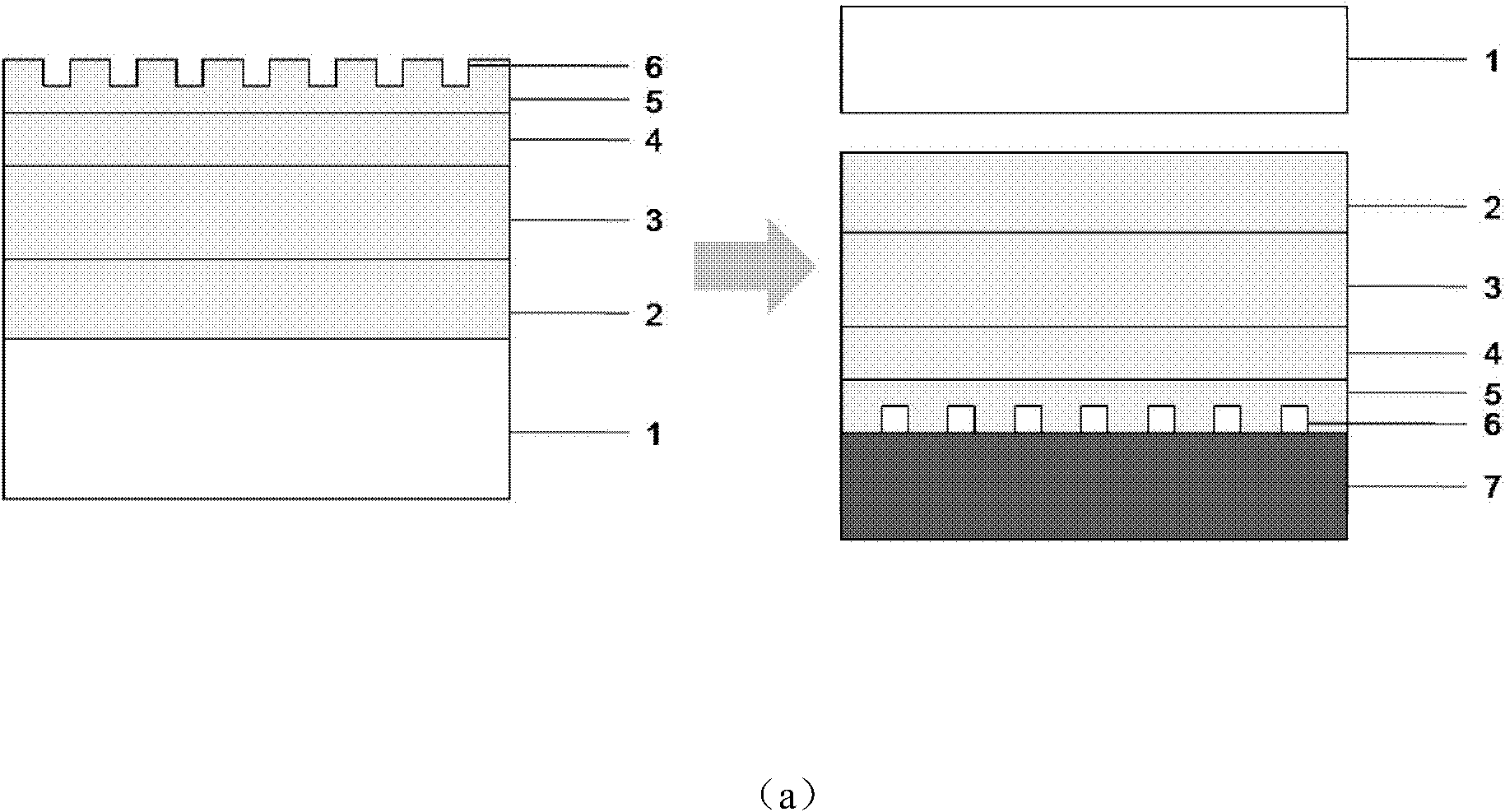

[0022] 2. Grow a GaN-based blue LED structure with a luminous wavelength of about 460nm on a sapphire substrate, and implement a conventional LED process to obtain an LED wafer with a transparent electrode layer (ITO or Ni / Au, etc.) on p-GaN. The steps 1. The prepared AAO film with periodic micro-nano structure is evenly and tightly adhered to the sur...

Embodiment 2

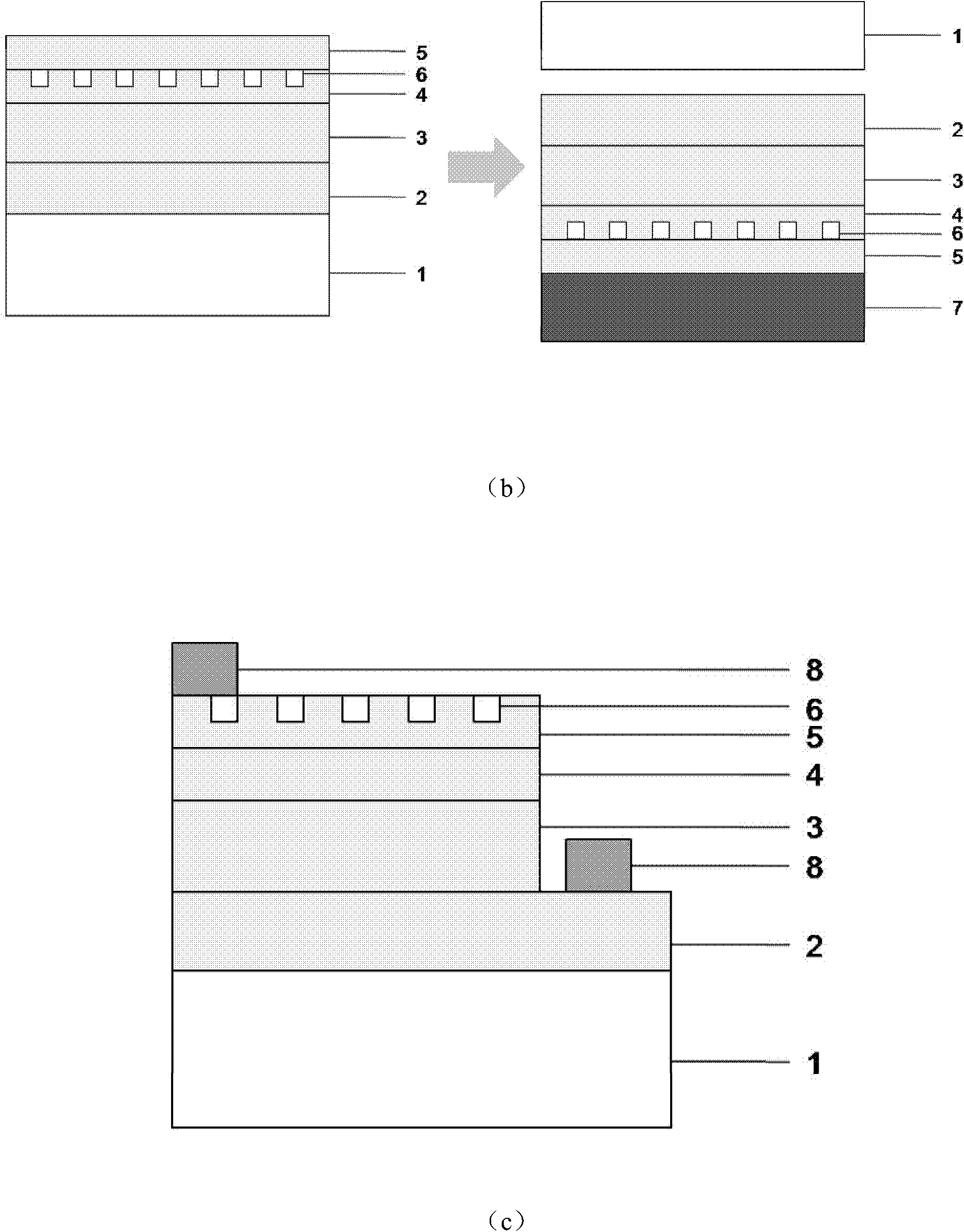

[0026] Embodiment 2: a high-power vertical structure (or ordinary flip-chip structure) GaN-based blue LED chip with a periodic micro-nano structure on the surface of p-GaN

[0027] 1. the first step of the present embodiment is the same as the first step of embodiment one, on this basis:

[0028] 2. Grow a GaN-based blue LED structure with a luminous wavelength of about 460nm on a sapphire substrate, and implement a conventional LED process to obtain an LED wafer in p-GaN, and use the AAO film with a periodic micro-nano structure prepared in step 1 It is evenly and tightly attached to the surface of the p-GaN layer at the top of the LED structure.

[0029] 3. Use the AAO template as a mask to etch the p-GaN layer with dry etching technology (ICP or RIE). After the etching is completed, remove the AAO template on the chip surface to obtain a periodic micro-nano structure The p-GaN surface has a high reflectivity to the light in the blue band.

[0030] 4. In order to prepare v...

Embodiment 3

[0032] Embodiment 3: GaN-based blue light LED chip with high-power vertical structure (or ordinary flip-chip structure) with periodic micro-nano structure and high-reflectivity metal reflective contact layer.

[0033] 1-3. the first three steps of this embodiment are the same as the first three steps of embodiment one, on this basis:

[0034] 4. On the surface of the transparent electrode (ITO or Ni / Au, etc.) of the LED chip with a periodic micro-nano structure, use electron beam evaporation technology to evaporate metals with high reflectivity such as Al or Ag to form a periodic micro-nano structure The high reflectivity electrode contacts the metal layer.

[0035] 5. In order to prepare a vertical structure LED, a thickened electrode such as Cr / Pt / Au is made on the high-reflectivity metal layer, and then the chip is bonded to silicon or other substrates by bonding, or a supporting liner is formed by electroplating Finally, use laser lift-off technology to remove the sapphir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com