Preparation method of aluminium-nitrogen co-doped silicon carbide absorbing material

A wave-absorbing material and co-doping technology, which is applied in the field of preparation of inorganic non-metallic materials, can solve the problems of cumbersome preparation process, long production cycle and complicated equipment, and achieve the effect of high purity, short production cycle and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

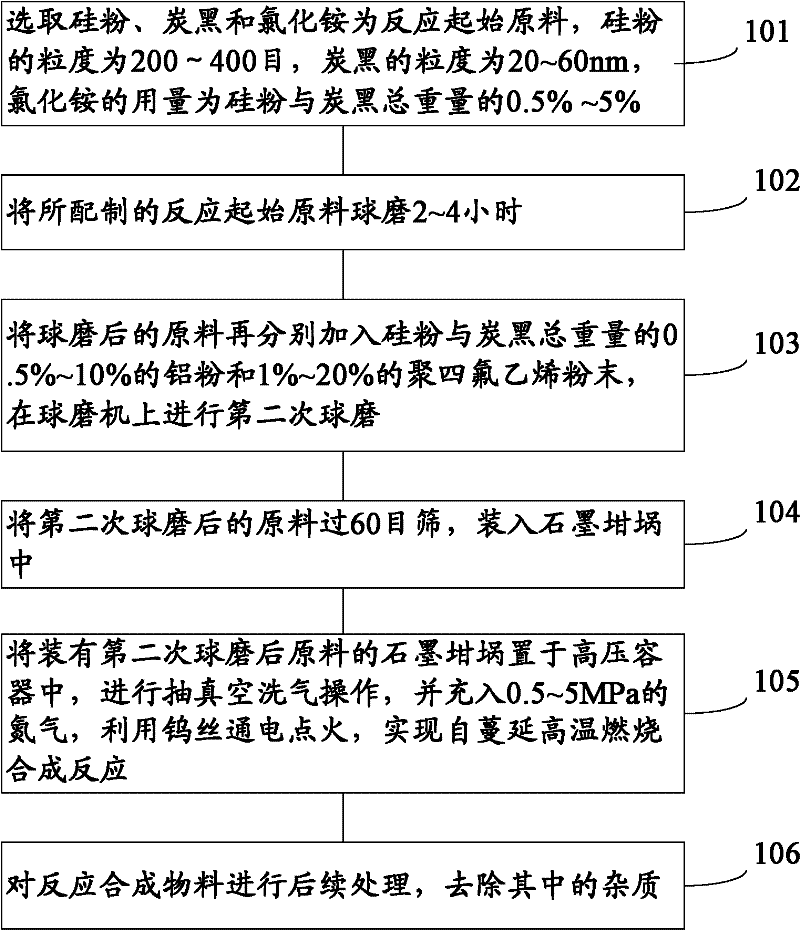

[0038] Reference figure 1 , Showing an embodiment of the preparation method of the aluminum-nitrogen co-doped silicon carbide absorbing material of the present invention, including the following steps:

[0039] Step 101, select silicon powder, carbon black and ammonium chloride (NH 4 Cl) is the starting material for the reaction, the particle size of the silicon powder is 200-400 mesh, the particle size of the carbon black is 20-60 nm, and the amount of ammonium chloride is 0.5% to 5% of the total weight of the silicon powder and the carbon black.

[0040] Among them, the purity of silicon powder and carbon black can be selected according to the actual situation. In order to make the reaction easier and the subsequent products have fewer impurities, the purity needs to be relatively high. In the present invention, the purity is selected to be 99.0% or more. Silicon fume and carbon black are used as starting materials for the reaction.

[0041] Step 102: Ball mill the above reaction s...

example 1

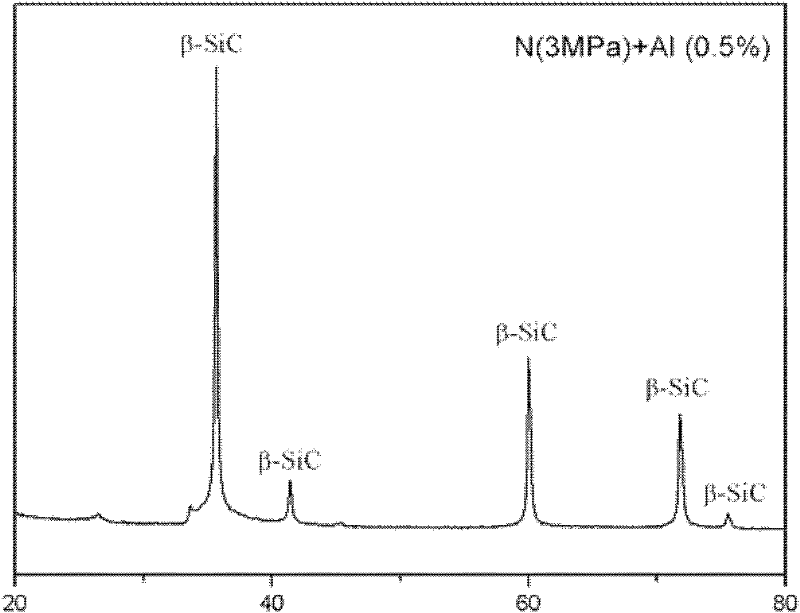

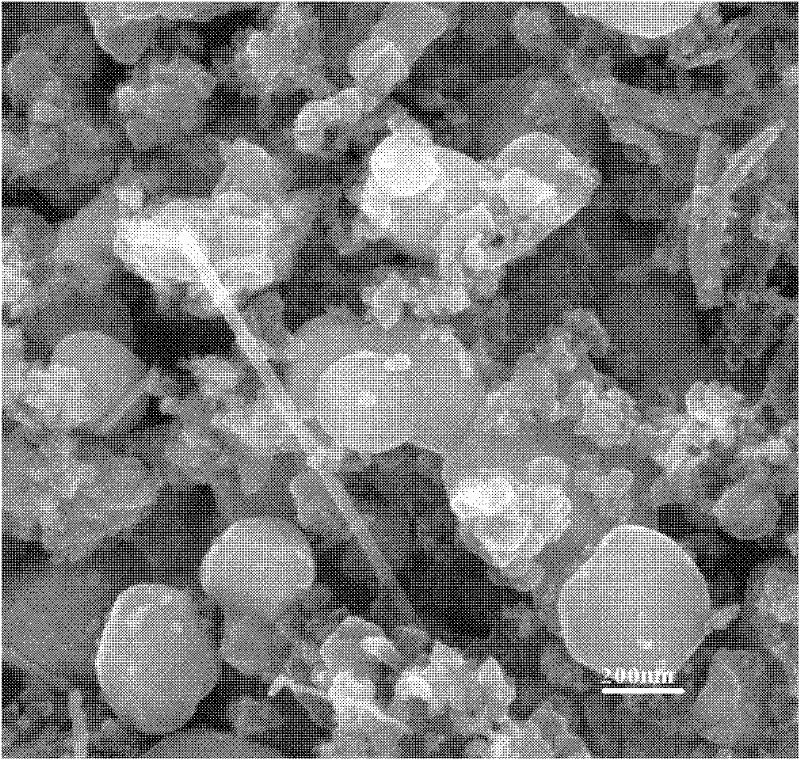

[0054] Put 140 grams of 250 mesh silicon powder, 60 grams of 50 nm carbon black and 2 grams of ammonium chloride in a high-energy ball mill for 3 hours. The ball milling medium is silicon carbide balls. Then add 1 g of aluminum (Al) powder and 12 g of polytetrafluoroethylene (PTFE) powder, and mix them evenly for 10 minutes. Pass the uniformly mixed powder through a 60-mesh sieve, and take 100 grams and place it in a graphite crucible. Place the crucible containing the processed powder in a high-pressure container, perform 3 times of vacuuming and purging, and then fill it with 3MPa high-purity nitrogen, use tungsten wire to ignite and ignite the combustion synthesis reaction. After the reaction is completed, The combustion products are cooled with the furnace in a nitrogen atmosphere. The combustion synthesis product is heated to 600°C in air and kept for 2 hours. Then, the products were pickled with 15% hydrochloric acid and 10% hydrofluoric acid, soaked for 3 hours each, a...

example 2

[0058] Put 136.5 grams of 300 mesh silicon powder, 60 grams of 50 nm carbon black and 1.965 grams of ammonium chloride in a high-energy ball mill for 3 hours. The milling medium is silicon carbide balls. Then add 3.93 grams of aluminum (Al) powder and 11.79 grams of polytetrafluoroethylene (PTFE) powder, and mix them evenly for 10 minutes. Pass the uniformly mixed powder through a 60-mesh sieve, and take 100 grams and place it in a graphite crucible. Place the crucible containing the processed powder in a high-pressure container, perform 3 times of vacuuming and purging, and then fill it with 3MPa high-purity nitrogen, use tungsten wire to ignite and ignite the combustion synthesis reaction. After the reaction is completed, The combustion products are cooled with the furnace in a nitrogen atmosphere. The combustion synthesis product is heated to 600°C in air and kept for 2 hours. Then, the products were pickled with 15% hydrochloric acid and 10% hydrofluoric acid, soaked for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com