Copper plating substrate-based method for preparing large-area graphene film

A technology of electroplating copper and graphene, applied in sputtering plating, ion implantation plating, gaseous chemical plating, etc., can solve the problems of high growth cost, small area, fragile substrate, etc., and achieve surface flatness High, simple method, high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of large-area graphene film based on electroplated copper substrate

[0026] The production process is as follows:

[0027] 1. Oxidize single crystal silicon with 200nm SiO 2 Oxide layer, and then sputter a seed layer of 50nmNi / 200nmCu on the oxide layer;

[0028] 2. Electroplate copper with a thickness of 4 μm on the seed layer of the above silicon wafer, the electroplating current is 2A, and the electroplating time is 18 minutes;

[0029] 3. Divide the silicon wafer into the size of the required substrate, load it into a quartz boat, put it into the constant temperature zone of the quartz tube, and raise the temperature to 1000°C in an atmosphere of 300 sccm argon;

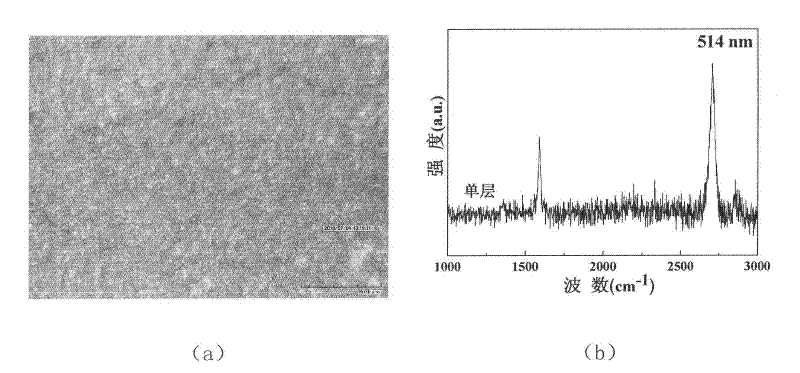

[0030] 4. When the target temperature is 1000°C, feed 10sccm methane, 200sccm hydrogen and 800sccm argon, grow for 3 minutes, and then anneal with the furnace in an atmosphere of 200sccm argon to produce a large-area graphene film. The experimental results are shown in the figure...

Embodiment 2

[0031] Embodiment 2: Prepare multilayer graphene film based on electroplated copper substrate

[0032] Steps 1, 2, and 3 are the same as Steps 1, 2, and 3 of Example 1, and the temperature is raised to 800° C.;

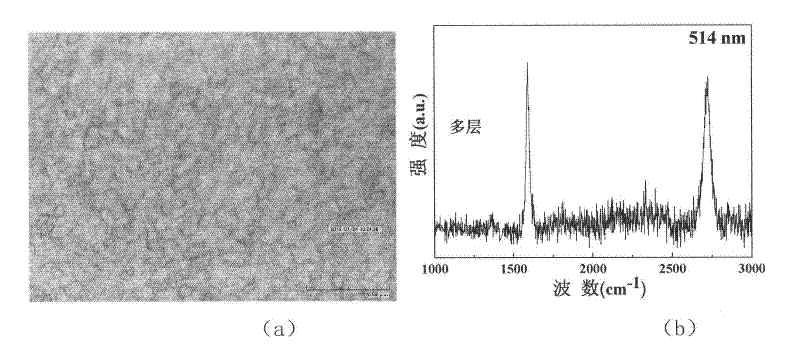

[0033] 4. When the target temperature is 800°C, feed 15sccm methane, 100sccm hydrogen and 400sccm argon, grow for 5 minutes, and then anneal in the furnace under the atmosphere of 200sccm argon to produce multilayer graphene. The experimental results are shown in the figure below: figure 2 (a) is the optical image after growth; figure 2 (b) is a Raman spectrum, and the Raman spectrum shows that graphene is multi-layered.

Embodiment 3

[0034] Example 3: Preparation of highly striped graphene film based on electroplated copper substrate

[0035] Step 1 is identical with embodiment 1 step 1;

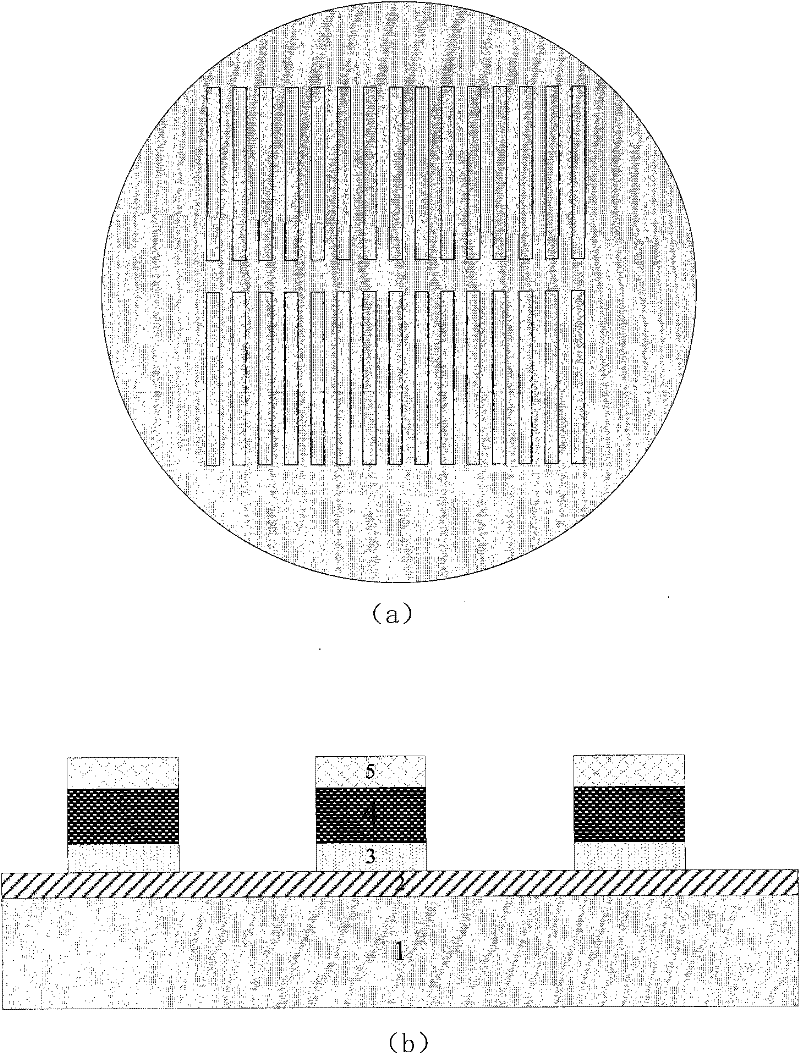

[0036] 2. Patterning of the seed layer: the photolithography version is as follows figure 1 As shown, the striped area is the area of electroplated copper (2μm×10μm), after coating a 5μm thick glue, photolithography and development;

[0037] 3. Electroplating copper: electroplating current 1.8A, electroplating time 15min, electroplating copper thickness 3.5um;

[0038] 4. Remove the photoresist after electroplating, then soak in the mixed solution of dilute sulfuric acid and hydrogen peroxide for tens of seconds after cleaning, remove the seed layer Ni / Cu, and divide it into substrates of corresponding sizes according to the image after cleaning (the substrate structure is shown in the figure below 5);

[0039] Example 3: Preparation of highly striped graphene film based on electroplated copper substrate

[0040] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com