Fluorene aniline structure-based organic photovoltaic materials

An organic optoelectronic material, fluorene aniline technology, applied in the field of preparation of new RGB materials, can solve the problems of serious environmental pollution, increase the cost and difficulty of complex material development, etc., and achieve high reaction yield, good thermal stability and processing performance. , the effect of simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

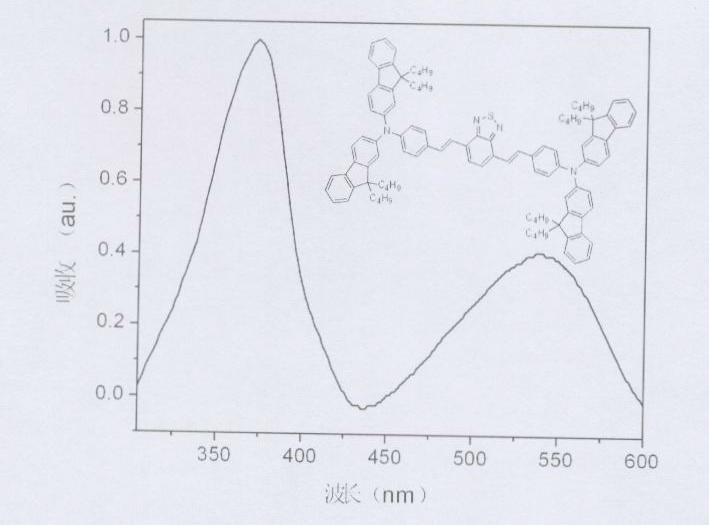

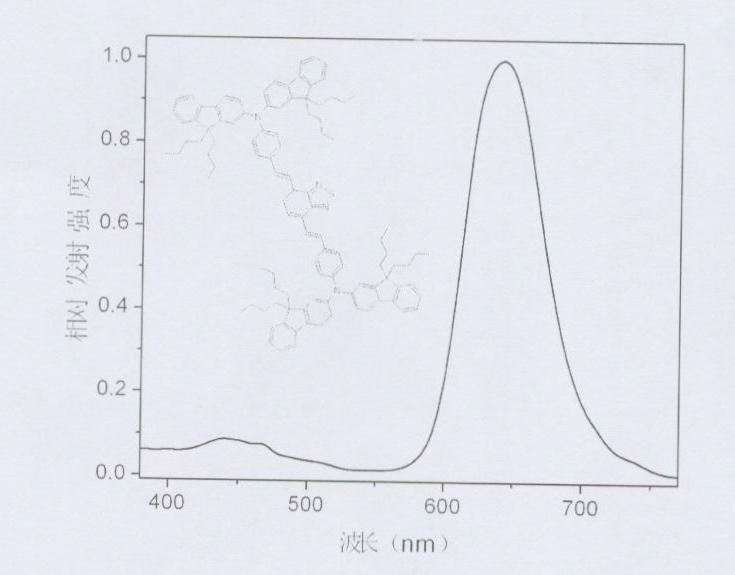

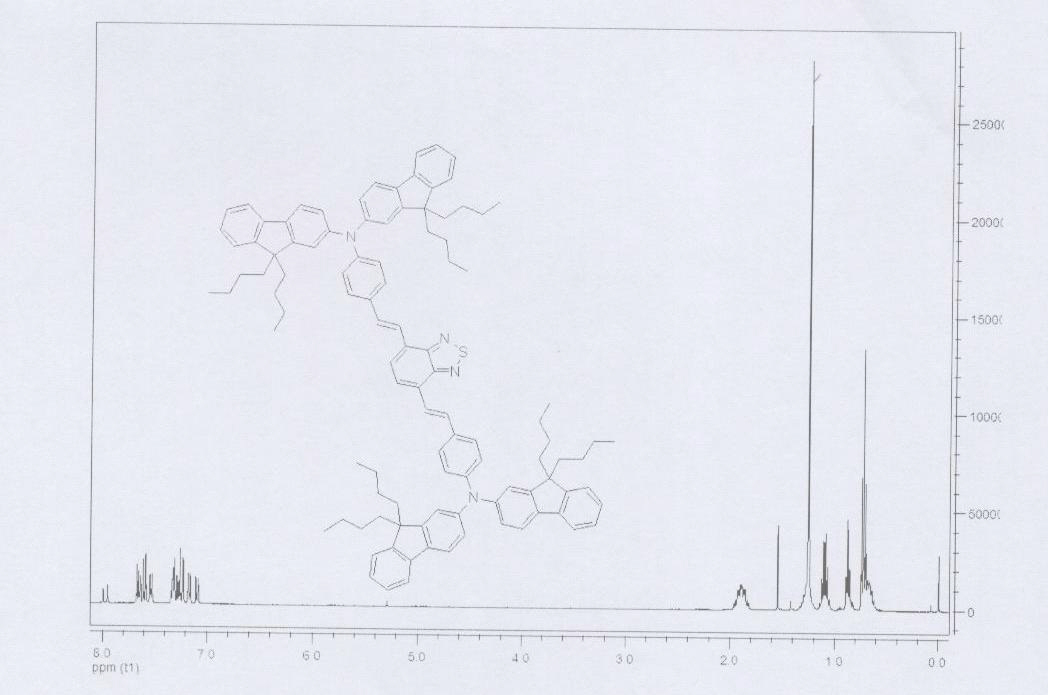

Image

Examples

Embodiment 1

[0061] Synthesis of vinyl-(9,9-di-n-butyl)-fluorene aniline (F)

[0062] Add vinylaniline, 9,9-dibutyl-2-bromofluorene, palladium catalyst, tert-butylphosphonium tetrafluoroborate, and sodium tert-butoxide into a two-necked flask equipped with a stirring bar, and the flask is dried After being sealed, the nitrogen is vacuumed three times, and the high-purity nitrogen must be treated in a strict anhydrous and oxygen-free device before use. Then, put the reaction device into an oil bath, and add toluene with a syringe. The toluene must be strictly treated before use to remove some impurities. The whole reaction system was reacted at 100°C for 24h. After the reaction was completed, toluene was distilled off under reduced pressure, washed with deionized water and extracted three times with dichloromethane, and the organic phase was spin-dried and passed through a silica gel column to obtain a light yellow solid.

Embodiment 2

[0064] Synthesis of 1-[N,N-bis(9,9-di-n-butyl-fluorene)aniline]-2-(9,9-di-n-butyl-fluorene)ethylene (FF)

[0065] Add the above-mentioned vinyl fluorene aniline (F), 9,9-di-n-butyl-2-bromofluorene, palladium catalyst, and potassium phosphate into a two-necked flask equipped with a stirring bar, and the flask is dried and airtight and then vacuumized three times. Nitrogen, high-purity nitrogen must be treated in strict anhydrous and oxygen-free devices before use. Then, put the reaction device into an oil bath, and add nitrogen-nitrogen dimethylacetamide (DMA) with a syringe. Before use, the DMA needs to be processed to remove some impurities. The whole reaction system was reacted for 24h under reflux. After the reaction was completed, DMA was distilled off under reduced pressure, washed with deionized water and extracted three times with dichloromethane, and the organic phase was spin-dried and passed through a silica gel column to obtain a light yellow solid.

Embodiment 3

[0067] Synthesis of 1-[N,N-bis(9,9-di-n-butyl-fluorene)aniline]-2-anthracene-ethylene (FEn)

[0068] Add the above-mentioned vinyl-(9,9-di-n-n-octyl)-fluorene-aniline, 9-bromoanthracene, palladium catalyst, and potassium phosphate into a two-necked flask equipped with a stirring bar, and vacuumize the flask three times after drying and sealing Nitrogen, high-purity nitrogen must be treated in strict anhydrous and oxygen-free devices before use. Then, put the reaction device into an oil bath, and add DMA solvent with a syringe. DMA must undergo strict treatment before use to remove some impurities. The whole reaction system was reacted for 24h under reflux. After the reaction was completed, DMA was distilled off under reduced pressure, washed with deionized water and extracted three times with dichloromethane, and the organic phase was spin-dried and passed through a silica gel column to obtain a light yellow solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com