Method for self-stabilized precipitation polymerization for in situ preparation of poly(4-ethenyl pyridine)polymer

A vinylpyridine, self-stabilizing precipitation technology, applied in the directions of pharmaceutical formulations, inactive medical preparations, coatings, etc., to achieve the effects of easy implementation, good stability, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

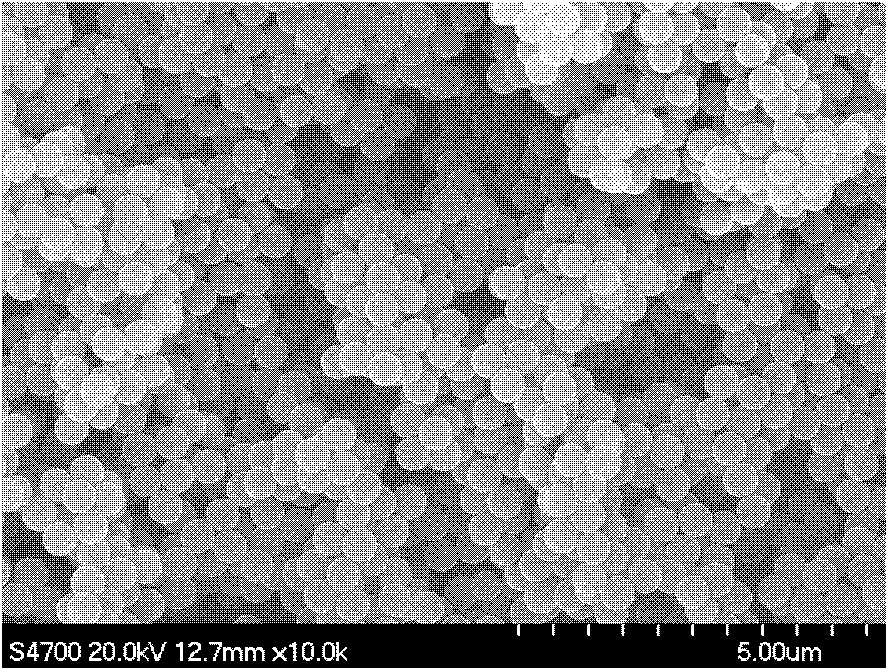

[0046] Add 2.625g of monomer 4-vinylpyridine, 0.0328g of initiator azobisisobutyronitrile, and 50ml of butyl acetate as the reaction medium into a 100ml three-necked flask, then put it in a water bath, and install a condenser The water pipe was connected with water, and the reaction temperature of the water bath was kept at 70°C, and the reaction was carried out under the protection of nitrogen for 8 hours. After the reaction, the obtained poly(4-vinylpyridine) polymer was centrifuged out from the emulsion by a centrifuge (4000 rpm, centrifugation time 10 min), cleaned and placed in a vacuum oven at 50°C for drying.

[0047] The average particle size of the obtained monodisperse P4VP particles was 502 nm, and the particle size distribution coefficient was 1.12%. , the yield is 78.85%, and its scanning electron micrograph is as figure 1 shown.

Embodiment 2

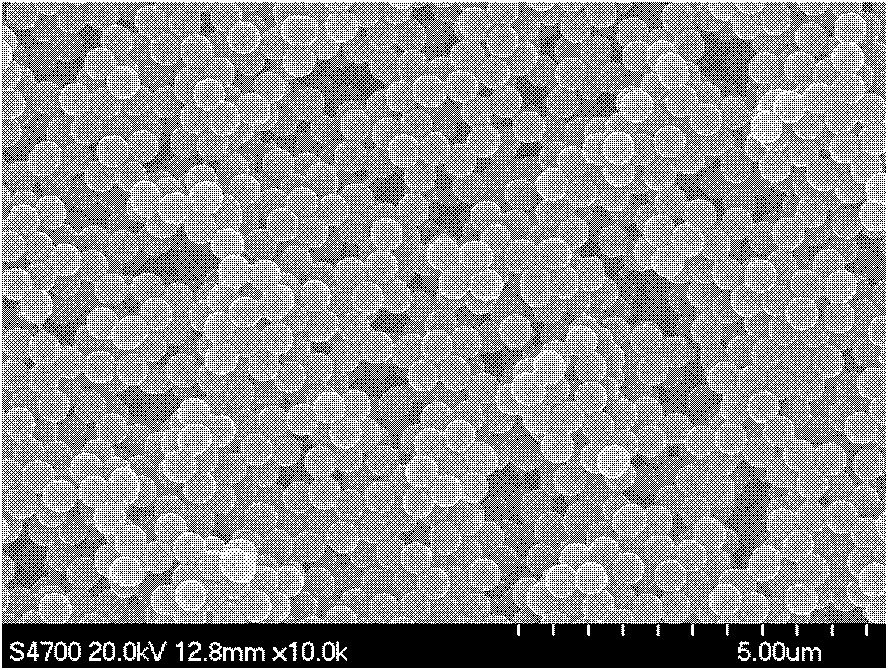

[0049] Put 2.625g of monomer 4-vinylpyridine, 0.0328g of initiator azobisisobutyronitrile, and 50ml of ethyl heptanoate as the reaction medium into a 100ml three-necked flask, then put it in a water bath, and put it on Condensate the water pipe and pass water, keep the reaction temperature of the water bath at 70°C, and react for 8 hours under the protection of nitrogen. After the reaction, the obtained poly(4-vinylpyridine) polymer was centrifuged out from the emulsion by a centrifuge (4000 rpm, centrifugation time 10 min), cleaned and placed in a vacuum oven at 50°C for drying.

[0050] The average particle diameter of gained monodisperse P4VP particle is 476nm, and particle size distribution coefficient is 1.43%, and productive rate is 69.42%, and its scanning electron micrograph is as follows figure 2 shown.

Embodiment 3

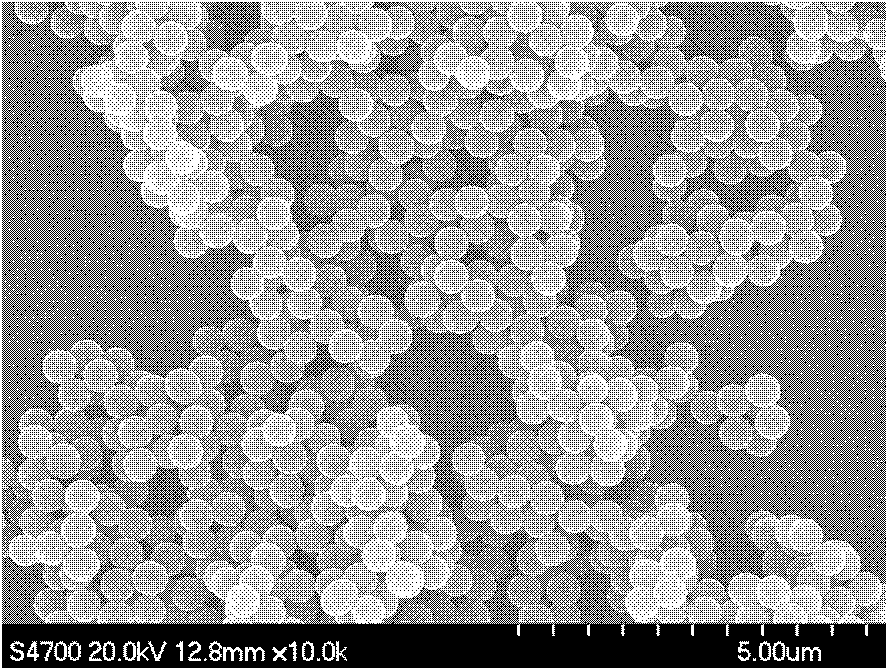

[0052] Add 2.625g of monomer 4-vinylpyridine, 0.0328g of initiator azobisisobutyronitrile, and 50ml of isoamyl acetate as the reaction medium into a 100ml three-necked flask, then put it in a water bath, and install Condensate the water pipe and pass water, keep the reaction temperature of the water bath at 70°C, and react for 8 hours under the protection of nitrogen. After the reaction, the obtained poly(4-vinylpyridine) polymer was centrifuged out from the emulsion by a centrifuge (4000 rpm, centrifugation time 10 min), cleaned and placed in a vacuum oven at 50°C for drying.

[0053] The average particle diameter of gained monodisperse P4VP particle is 492nm, and particle size distribution coefficient is 1.38%, and productive rate is 67.94%, and its scanning electron micrograph is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com