Method for preparing hydrophilic drug microsphere through spray drying process

A hydrophilic drug, spray-drying technology, applied in pharmaceutical formulations, organic active ingredients, medical preparations with non-active ingredients, etc. It is difficult to mass-produce and other problems, and achieves the effect of overcoming a large volume of oily substances and a large amount of volatile solvents for washing, rounding the shape, and reducing organic residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

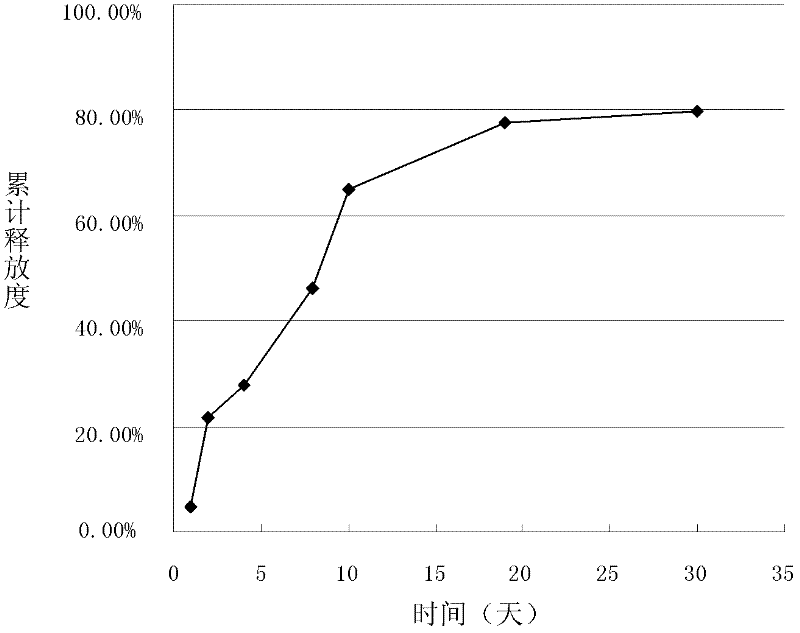

[0039]The preparation of embodiment 1 doxorubicin hydrochloride sustained-release microspheres

[0040] Raw material prescription:

[0041]

[0042]

[0043] The preparation process is as follows:

[0044] (1) Configure spray liquid

[0045] Dissolve the acrylic resin II in the ethanol solution, then add glyceryl monostearate and castor oil and stir evenly;

[0046] (2) Primary package of raw materials

[0047] Uniformly disperse doxorubicin hydrochloride in sesame oil containing Span80 to prepare S / O 1 type suspension.

[0048] (3) Homogeneous emulsification of spray liquid

[0049] Add the suspension prepared in (2) to the spray liquid obtained in (1) for homogeneous emulsification, the homogenization temperature is 50 °C, the speed of the high-speed shear homogenizer is 14000 rpm, and the time is 6 minutes to obtain S / o 1 / O 2 type spray emulsion;

[0050] (4) Spray drying: Spray dry the above-mentioned spray emulsion, the air inlet temperature is 160°C, the...

Embodiment 2

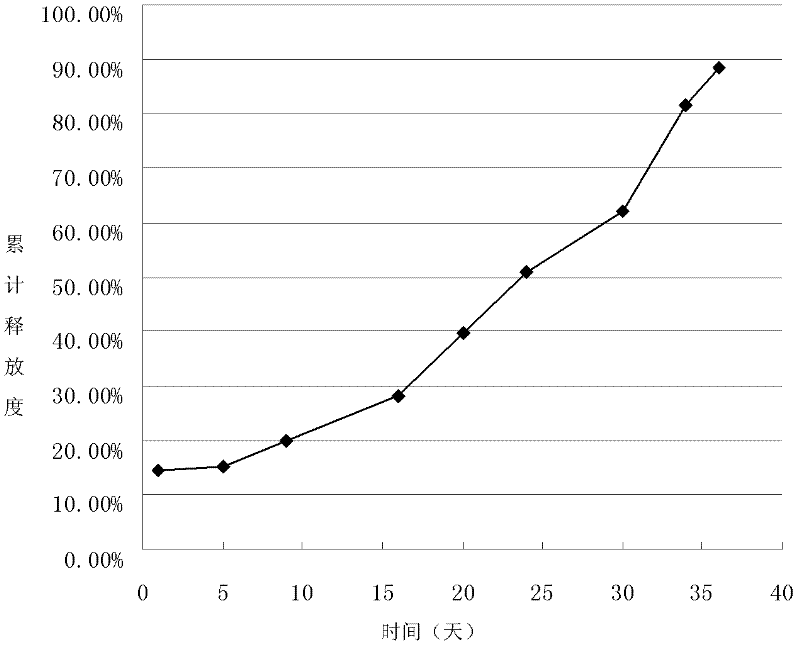

[0052] Example 2 Preparation of 5-fluorouracil sustained-release microspheres

[0053] Raw material prescription:

[0054]

[0055] The preparation process is as follows:

[0056] (1) Configure spray liquid

[0057] Dissolve acrylic resin Eudragit L100 and acrylic resin Eudragit S100 in ethanol solution, then add glyceryl monostearate and castor oil and stir well.

[0058] (2) Primary package of raw materials

[0059] Disperse 5-fluorouracil evenly in peanut oil containing Span80 to make S / O 1 type suspension.

[0060] (3) Homogeneous emulsification of spray liquid

[0061] Add the suspension prepared in (2) to the spray liquid obtained in (1) for homogeneous emulsification, the homogenization temperature is 50°C, the speed of the high-speed shear homogenizer is 10000 rpm, and the time is 9min, to obtain S / o 1 / O 2 type spray emulsion.

[0062] (4) Spray drying: Spray dry the above-mentioned spray emulsion, the air inlet temperature is 145°C, the air outlet temper...

Embodiment 3

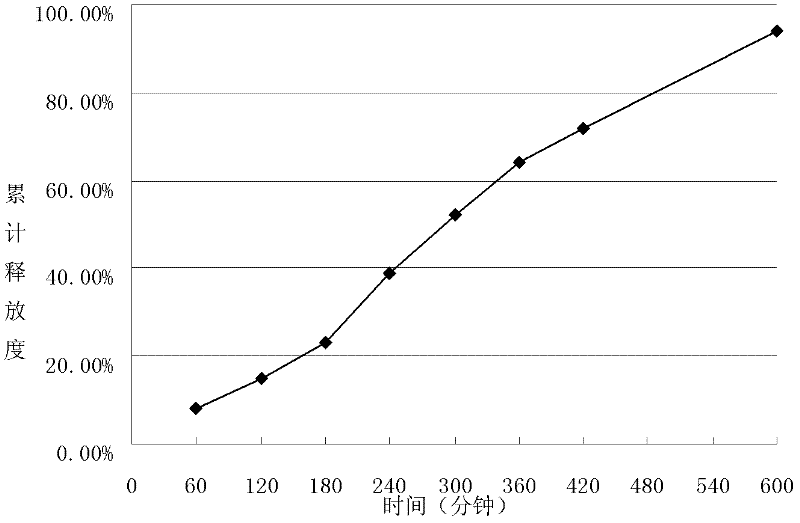

[0064] The preparation of embodiment 3 metformin hydrochloride sustained-release microspheres

[0065] Raw material prescription:

[0066]

[0067] The preparation process is as follows:

[0068] (1) Configure spray liquid

[0069] Dissolve acrylic resin Eudragit L100 in ethanol solution, then add glyceryl monostearate and castor oil and stir well.

[0070] (2) Primary package of raw materials

[0071] Disperse metformin hydrochloride evenly in sesame oil containing Span80, and prepare S / O 1 type suspension.

[0072] (3) Homogeneous emulsification of spray liquid

[0073] Add the suspension prepared in (2) to the spray liquid obtained in (1) for homogeneous emulsification, the homogenization temperature is 50°C, the speed of the high-speed shear homogenizer is 20000 rpm, and the time is 4min, to obtain S / o 1 / O 2 type spray emulsion.

[0074] (4) spray drying

[0075] The above-mentioned spray emulsion was spray-dried, the inlet air temperature was 155°C, the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com