Composite protease, preparation method and application thereof

A compound protease and application technology, applied in the fields of microbiology and biochemistry, can solve the problems of high cost, complex enzyme compounding process, and compound enzymatic hydrolysis can not achieve the effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

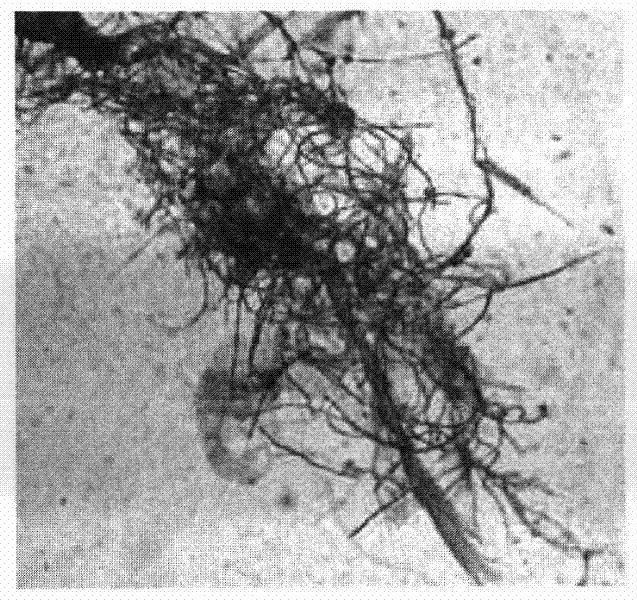

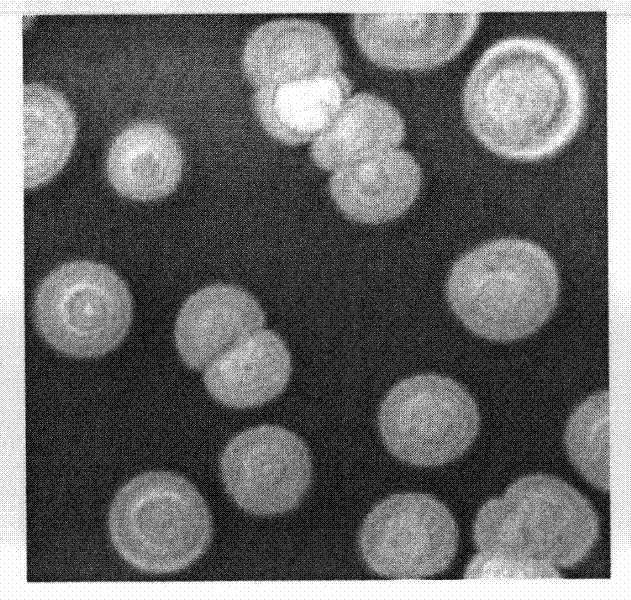

[0122] Isolation and Screening of Complex Protease-producing Strains

[0123] 1) Sampling was taken from the feather-rich garbage soil, sewer silt and sewer water around the Fujian breeding factory, and continuous enrichment culture was carried out with feather meal as the only carbon and nitrogen source. Take 10g soil sample in a 250ml Erlenmeyer flask, fully suspend it with 100ml sterile water to make a bacterial suspension, and then use different dilutions (10 -1 、10 -2 、10 -3 、10 -4 、10 -5 ) coated with feather meal agar plate, feather meal agar medium consists of (g / L): NH 4 Cl0.5, NaCl0.5, K 2 HPO 4 0.3, KH 2 PO 4 0.4, MgSO 4 ·7H 2 O 0.1, yeast extract 0.1, feather meal 10, agar 20 (pH 7.2-7.5), cultured upside down at 30°C for 3 days. Select a single colony with an obvious transparent circle, and use feather meal agar slant to separate and purify 3-5 times. The purified strains are enriched and cultivated with the improved Gaoshi No. 1 medium. The improved ...

Embodiment 2

[0133] Preparation of complex protease

[0134] Take the high-performance composite protease-producing bacterial strain screened in Example 1, inoculate it on the improved Gaoshi No. 1 slant, place it in a constant temperature biochemical incubator, and cultivate it at 37°C for 2-3 days, until a thick protease grows on the slant. thick bacterial lawn, and the surface of the bacterial lawn is light pink, take it out, and store it in a 4°C refrigerator for later use, otherwise continue to cultivate. The modified Gaoshi No. 1 medium consists of (g / L): KNO 3 1. Soluble starch 10, corn starch 5, dextrin 5, K 2 HPO 4 0.5, MgSO 4 ·7H 2 O 0.5, NaCl 0.5, FeSO 4 0.01, composed of agar 20 (pH7.2-7.4).

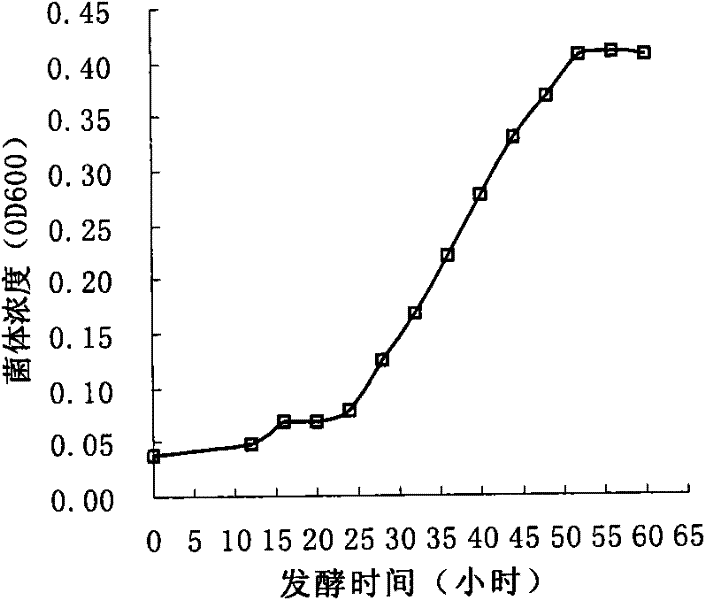

[0135] Pick a part of the bacterial lawn cultivated above, inoculate it into 100ml seed medium, place it in a constant temperature shaking incubator, and cultivate it at 37°C and 150rpm for 16-22h. After the bacterial concentration (OD600nm) reaches 0.5-0.8, take it out and place...

Embodiment 3

[0140] Protease Activity Analysis Method

[0141] (1) Determination method of keratinase activity

[0142] Take 400ul of the supernatant of the enzyme solution centrifuged at 10000rpm for 5min in a test tube, add 1.6ml of 0.4% (w / v) keratin azure (the control group is replaced by the same volume of pH9.0, 50mM Tris-HCl buffer solution), seal with plastic wrap, React on a constant temperature shaker at 50°C and 300 rev / min for 1 h, centrifuge at 5000 rpm for 15 min, take the supernatant and measure the absorbance at 595 nm.

[0143] One enzyme activity unit (U) is defined as: an increase of 0.1 per hour in the absorbance value at 595 nm is defined as one enzyme activity unit.

[0144] Keratinase activity U is calculated according to the following formula:

[0145] U = ( A - A 0 ) 0.4 × ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific vitality | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com