Preparation and Application of Acidic Media Black t-Barium Sulfate Adsorption Material

A technology of adsorption material and medium black, which is applied in the direction of adsorption water/sewage treatment, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of complex preparation conditions, few types of heavy metals, high cost of raw materials, etc., and achieve easy raw materials Good adsorption performance and short adsorption time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

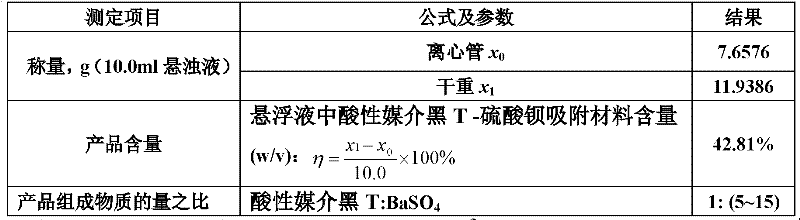

[0027] Soluble barium chloride is selected as the skeleton material. The barium chloride is added with water to configure a barium chloride solution with a concentration of 7% by weight. The sodium sulfate is added with water to be configured as a 3% sodium sulfate solution by weight percentage. In 500ml of 20mmol acidic medium black T solution, under magnetic stirring conditions, add 500ml of 3% sodium sulfate solution, stir evenly, then slowly add 500ml of barium chloride solution with a mass percentage concentration of 7%, and mix the reaction for 10- In 30 minutes, the precipitate was settled for 1 hour, washed with water three times (3×1000ml) to precipitate, left overnight, and the precipitate was collected, which was the acidic medium black T-barium sulfate adsorption material of the present invention in the form of a suspension.

[0028] The above-mentioned suspension product can also be made into a solid adsorption material product through centrifugation, drying, and c...

Embodiment 2

[0033] The above-mentioned acid media black T-barium sulfate adsorption material produced by the method of the present invention is used to treat heavy metal pollutant wastewater. Prepare mixed samples containing 5 heavy metals in a 100ml Erlenmeyer flask: 52.800mg / L copper, 53.200mg / L lead, 53.400mg / L chromium, 54.800mg / L cadmium, 50.15mg / L zinc. Add 0.2%, 0.4%, and 0.6% of the mixed sample weight of acidic medium black T-barium sulfate adsorption material, react for 30 minutes and then centrifuge. The data measured by ICP-OES are shown in Table 2. Adding 0.4% can simultaneously absorb more than 91% The removal rates of copper, lead, chromium, cadmium and zinc are relatively low.

[0034] Table 2 Adsorption experiment data of heavy metal mixed solution

[0035] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com