Preparation method of silicon carbide fiber reinforced silicon carbide composite material

A technology of silicon carbide fiber and composite material, applied in the field of preparation of silicon carbide fiber reinforced silicon carbide composite material, can solve problems such as improvement and stability of unfavorable material properties, high material porosity, unsatisfactory and the like, and achieve cracking quality The effect of high retention rate, improved bonding strength, and shortened preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of silicon carbide fiber reinforced silicon carbide composite material of the present invention, comprises the following steps:

[0028] (1) Material preparation:

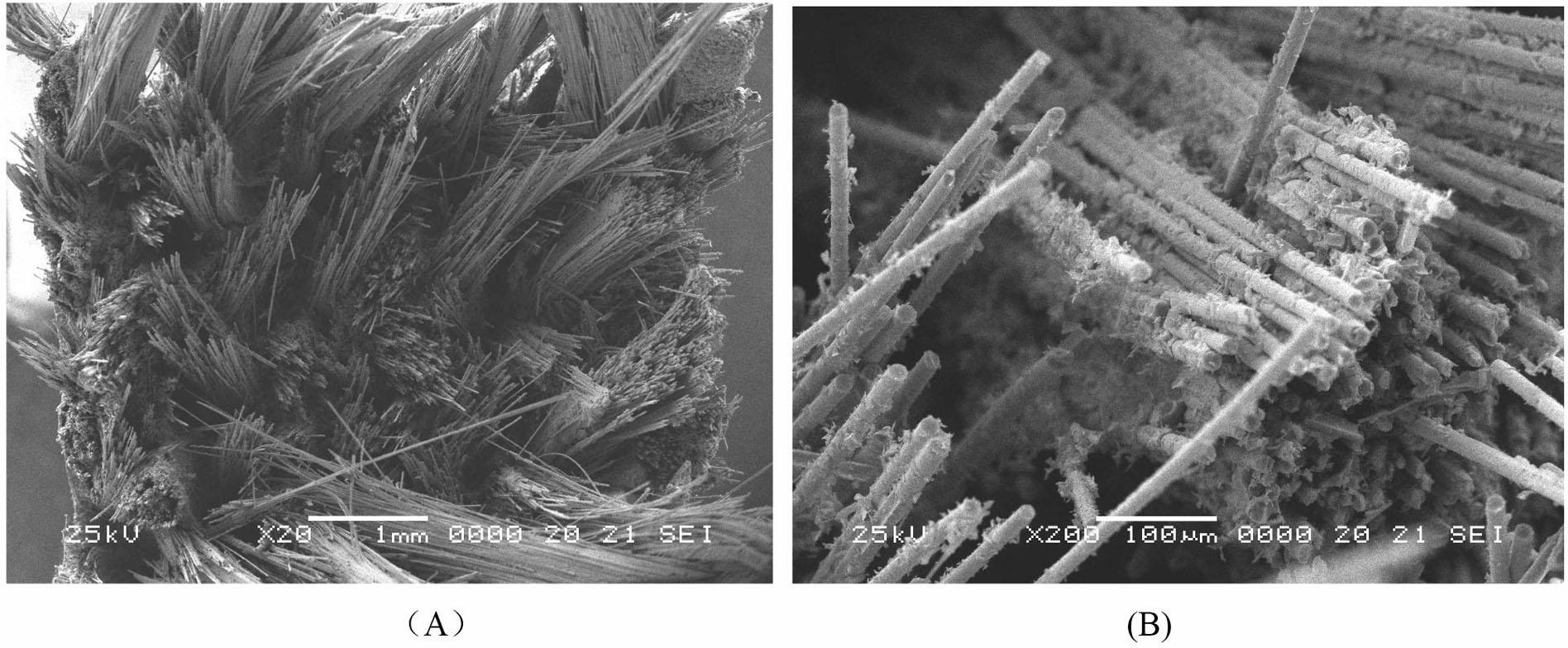

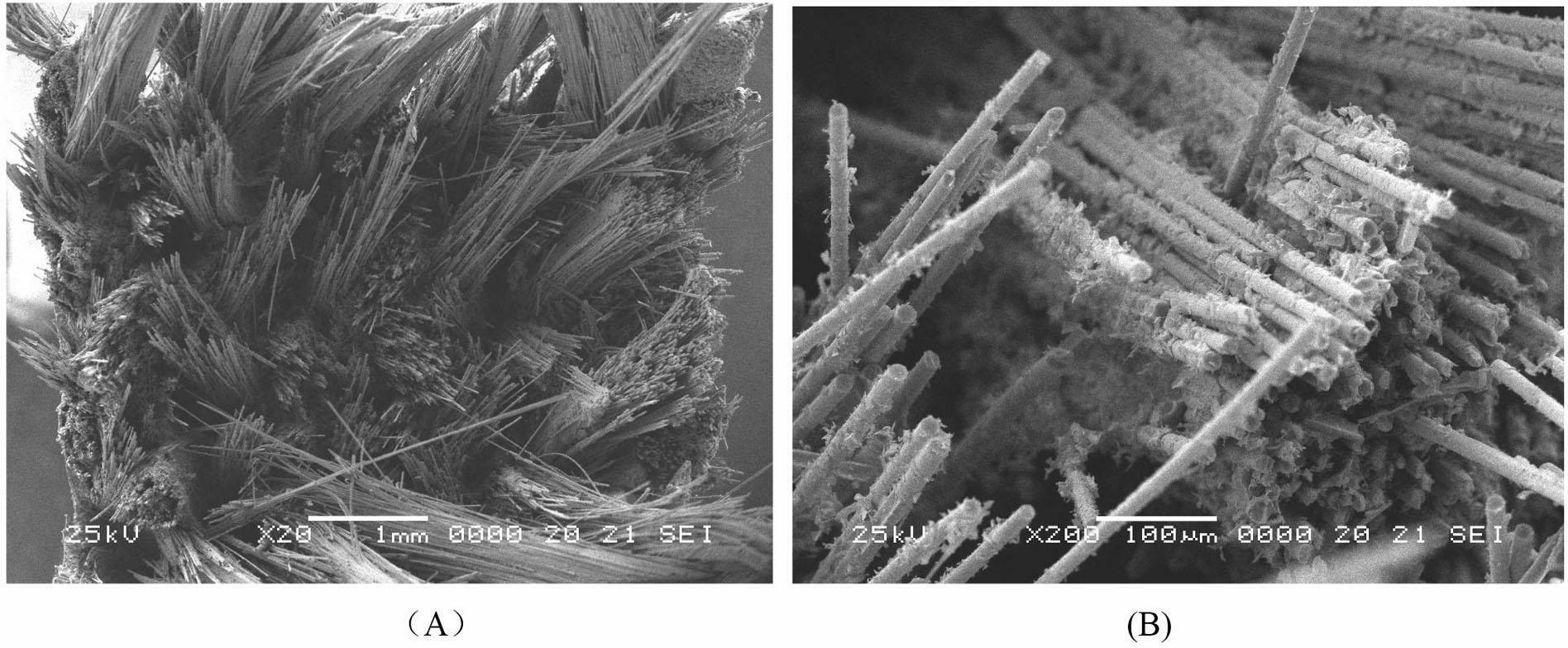

[0029] a. Using SiC fiber as raw material, SiC fiber braided parts are prepared by three-dimensional four-way weaving process;

[0030] b. Prepare Si-H and -CH=CH 2 group of liquid SiC ceramic precursors (LPVCS).

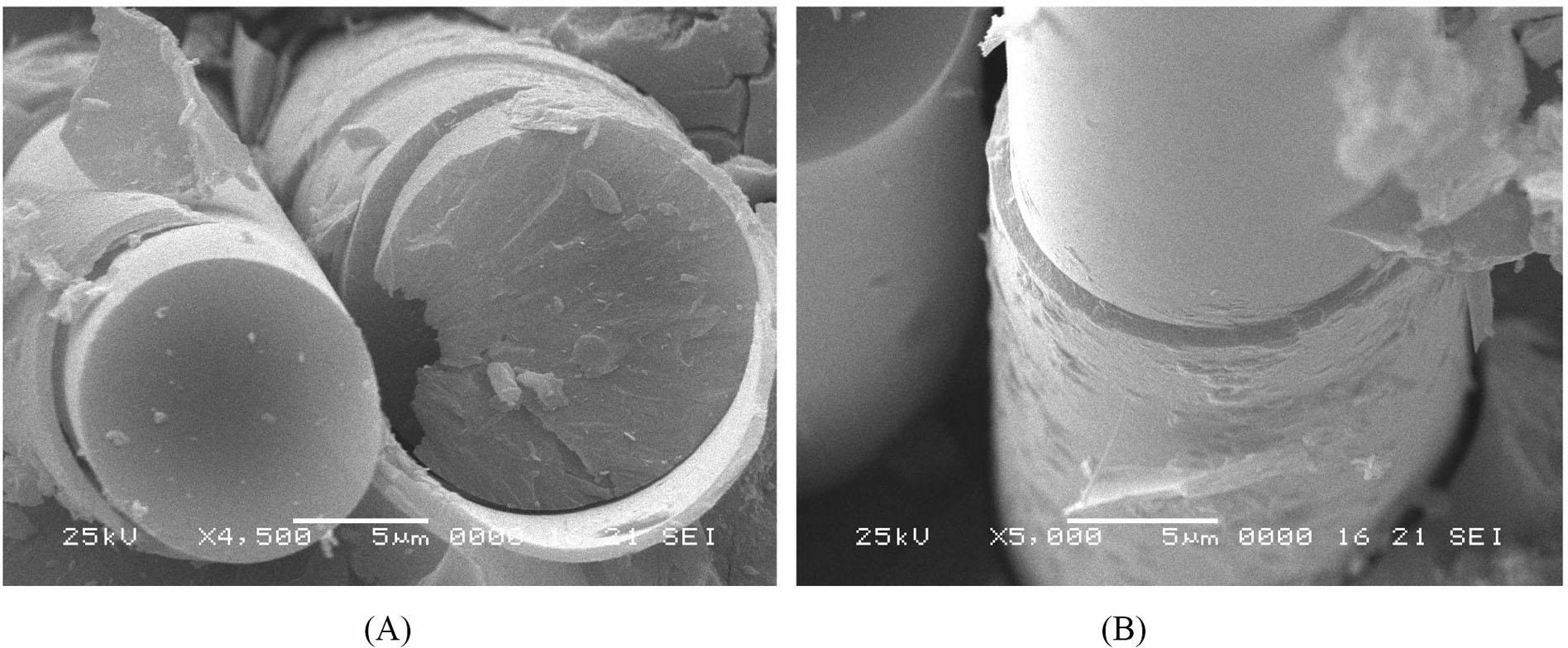

[0031] (2) Deposition of carbon coating: using methane or propylene as the raw material gas, the SiC fiber braided piece is placed in a vacuum furnace for chemical vapor deposition using a differential pressure method, and a carbon coating is deposited on the surface of the SiC fiber braided piece. The process conditions of chemical vapor deposition are: the carbon source is propylene, the flow rate is 0.01m 3 h -1 ; The carrier gas is hydrogen, the flow rate is 0.10m 3 h -1 , the atmosphere pressure is 500Pa; the deposition temperature is 1300°C, and the deposit...

Embodiment 2

[0040] A kind of preparation method of silicon carbide fiber reinforced silicon carbide composite material of the present invention, comprises the following steps:

[0041] (1) Material preparation:

[0042] a. Using SiC fiber as raw material, SiC fiber braided parts are prepared by three-dimensional four-way weaving process;

[0043] b. Prepare Si-H and -CH=CH 2 group of liquid SiC ceramic precursors (LPVCS).

[0044] (2) Deposition of carbon coating: using methane or propylene as the raw material gas, the SiC fiber braided piece is placed in a vacuum furnace for chemical vapor deposition using a differential pressure method, and a carbon coating is deposited on the surface of the SiC fiber braided piece. The process conditions of chemical vapor deposition are: the carbon source is propylene, the flow rate is 0.05m 3 h -1 ;The carrier gas is hydrogen, the flow rate is 0.20m 3 h -1 , the atmosphere pressure is 1500Pa; the deposition temperature is 1200°C, and the deposit...

Embodiment 3

[0053] A kind of preparation method of silicon carbide fiber reinforced silicon carbide composite material of the present invention, comprises the following steps:

[0054] (1) Material preparation:

[0055] a. Using SiC fiber as raw material, SiC fiber braided parts are prepared by three-dimensional four-way weaving process;

[0056] b. Prepare Si-H and -CH=CH 2 group of liquid SiC ceramic precursors (LPVCS).

[0057] (2) Deposition of carbon coating: using methane or propylene as the raw material gas, the SiC fiber braided piece is placed in a vacuum furnace for chemical vapor deposition using a differential pressure method, and a carbon coating is deposited on the surface of the SiC fiber braided piece. The process conditions of chemical vapor deposition are: the carbon source is propylene, the flow rate is 0.10m 3 h -1 ;The carrier gas is hydrogen, the flow rate is 0.15m 3 h -1 , the atmosphere pressure is 200Pa; the deposition temperature is 1400°C, and the depositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com