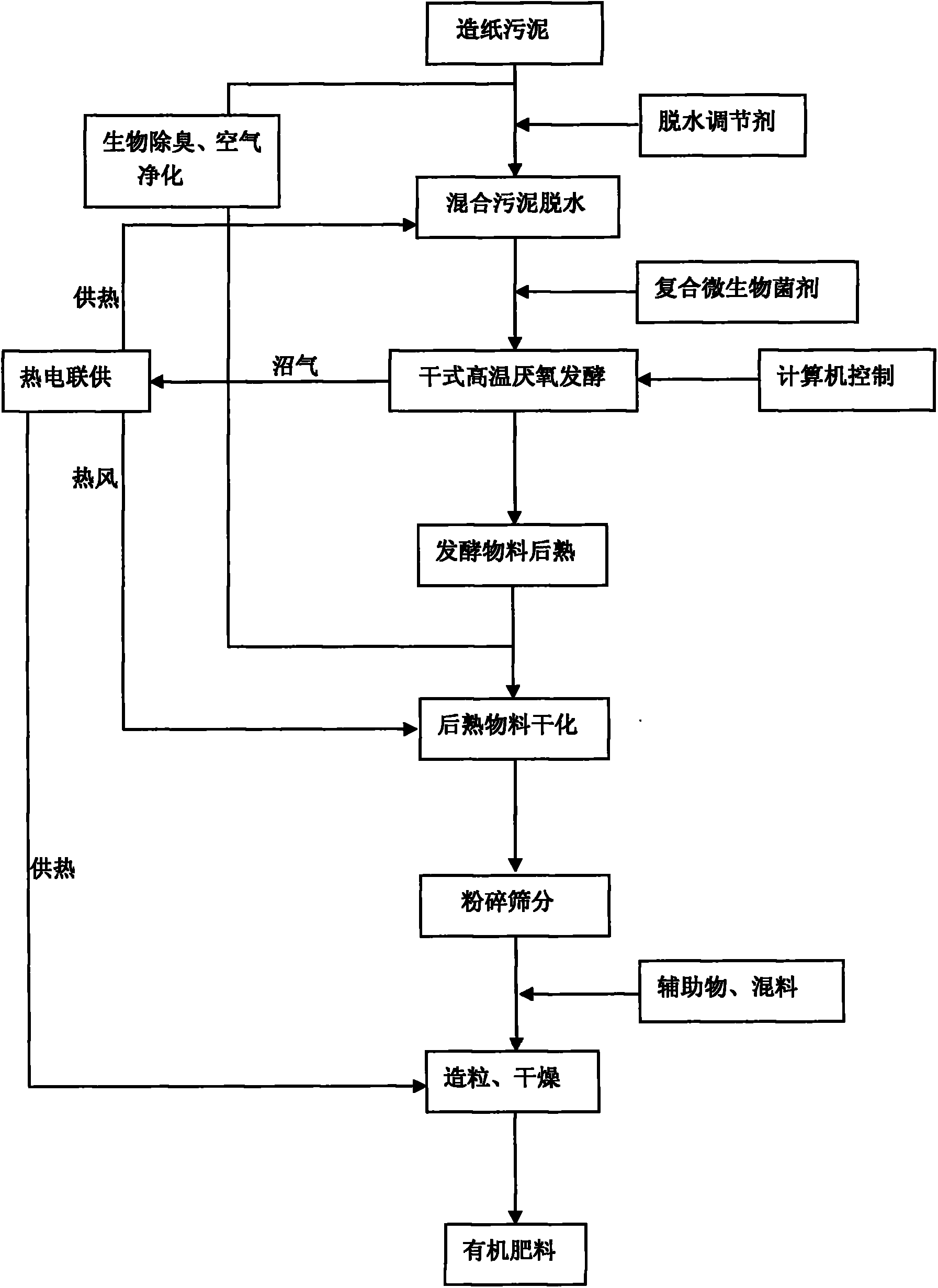

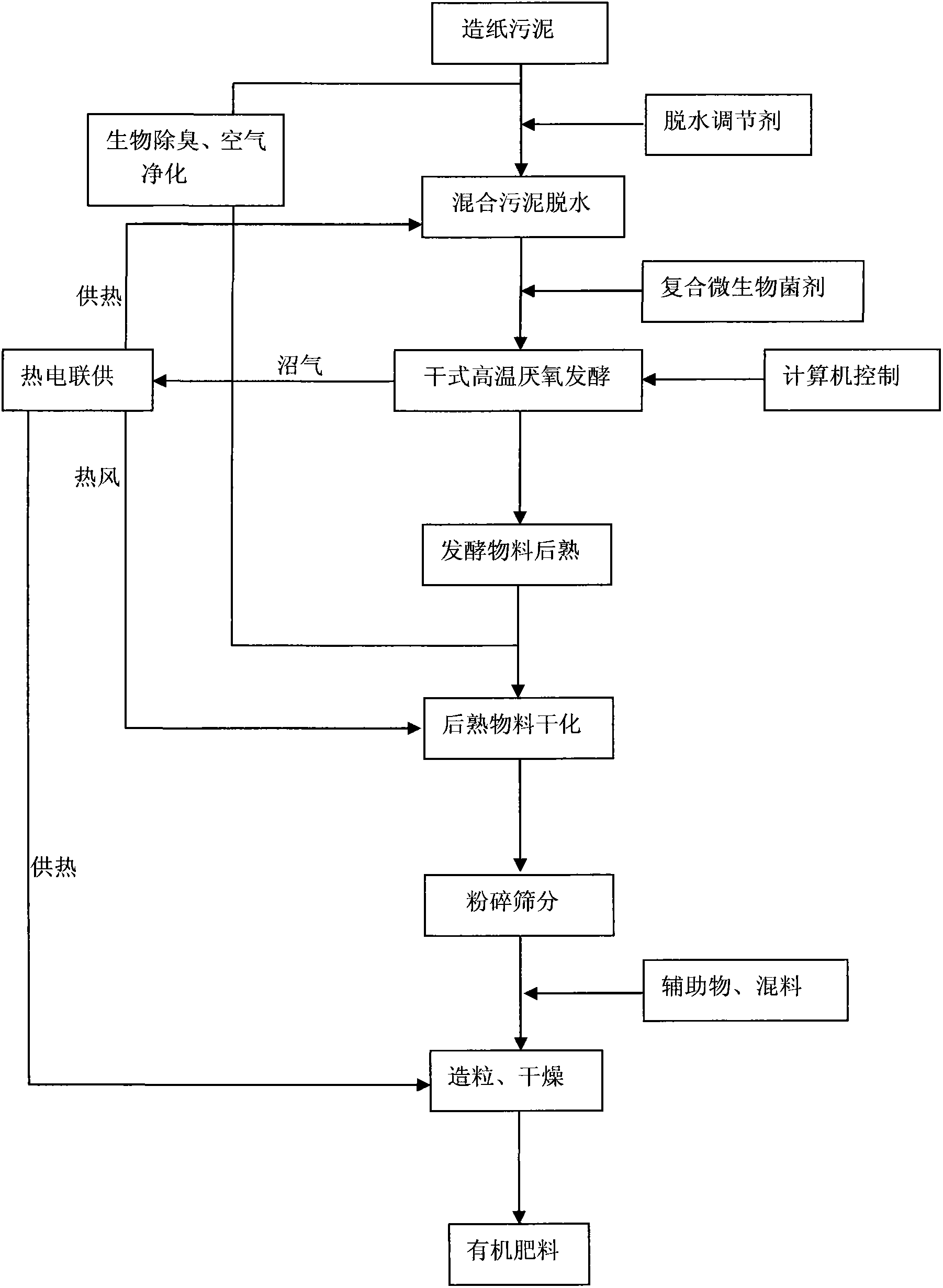

Method for preparing organic fertilizer by dry-type high-temperature anaerobic fermentation of papermaking sludge

A technology of high-temperature anaerobic fermentation and papermaking sludge, which is applied to organic fertilizers, sewage/sludge fertilizers, sludge treatment, etc., to achieve good shape, reduce ammonia volatilization, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Adjusting the water content of papermaking sludge to prepare mixed sludge

[0036] Papermaking sludge with a moisture content of 75-80% is used as raw material, and the papermaking sludge and regulator are mixed uniformly at a mass ratio of 2.5:2-3.0:2 without standing still. The above mixture is sent to extrusion dehydration equipment through a conveyor to obtain mixed sludge with a moisture content of 50-55%, a carbon / nitrogen mass ratio (C / N) of 25:1-35:1, and an organic matter content of 60%-65%. .

[0037] (2) High temperature anaerobic fermentation reaction of mixed sludge in fermentation bin

[0038] The mixed sludge prepared in the step (1) enters the fermentation bin, and is fermented according to the mass ratio of the dry powder complex microbial flora to the mixed sludge of 1.5-2.0%. The mixed material reacts in the fermentation bin under the control of automatic temperature control and stirring equipment. The computer system controls the air supply i...

Embodiment 2

[0046] (1) Adjusting the water content of papermaking sludge to prepare mixed sludge

[0047] Papermaking sludge with a moisture content of 75-80% is used as raw material, and the papermaking sludge and regulator are mixed uniformly at a mass ratio of 2.5:2-3.0:2 without standing still. The above mixture is sent to extrusion dehydration equipment through a conveyor to obtain mixed sludge with a moisture content of 50-55%, a carbon / nitrogen mass ratio (C / N) of 25:1-35:1, and an organic matter content of 60%-65%. . The energy of the press dewatering equipment for adjusting the water content of the paper sludge is provided by the biogas produced during the fermentation process.

[0048] Steps (2)-(5) are the same as in Example 1.

Embodiment 3

[0050] Step (1) is with embodiment 1.

[0051] (2) High temperature anaerobic fermentation reaction of mixed sludge in fermentation bin

[0052] The mixed sludge prepared in the step (1) enters the fermentation bin, and is fermented according to the mass ratio of the dry powder complex microbial flora to the mixed sludge of 1.5-2.0%. The mixed material reacts in the fermentation bin under the control of automatic temperature control and stirring equipment. The computer system controls the air supply in the early stage and cultivates aerobic microorganisms to make the papermaking sludge decompose, dehydrate and deodorize in a short time. The temperature control is automatically adjusted in the fermentation chamber. After 1 day, the temperature rises to 37°C, and the temperature is maintained at 37°C for 2 days. During this process, intermittent stirring is maintained every 3 hours, and the stirring time is 30 minutes each time. Then, after 1.5 days, the temperature rises to 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com