A kind of preparation method of nanocomposite superhard film

A nano-composite, thin-film technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of poor silicon conductivity, complex smelting and processing technology, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

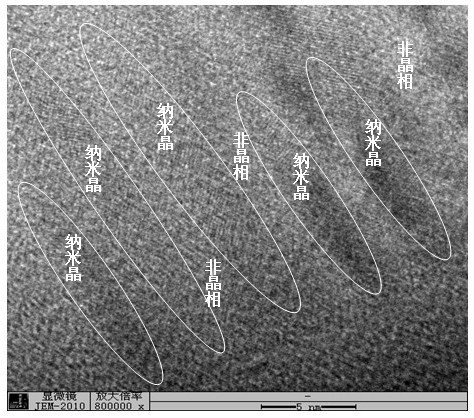

Image

Examples

Embodiment 1

[0017] Nanocrystalline TiN / Amorphous Si 3 N 4 Preparation of nanocomposite films:

[0018] (1) After the substrate is degreased and polished, put it into acetone and ethanol for ultrasonic cleaning, take it out, dry it with nitrogen, put it in a vacuum chamber, and vacuum it to 5.0×10 -4 Pa;

[0019] (2) Feed N from the source of the magnetic filter cathode 2 / Ar mixed gas, where Ar flow rate is 7.0sccm, N 2 The flow rate is 21.0sccm, and the cathode high-purity Ti target (purity 99.96%) is struck to generate arc discharge. The cathode current is 70A, the source coil current is 0.25A, the magnetic filter coil current is 3.0A, and the exit coil current is 1.5A to extract the ion beam. Deposit a 50nm thick TiN film on the substrate with a working pressure of 0.2Pa;

[0020] (3) Then the Ar ion beam is generated by the Kaufman ion gun, the Ar flow rate is 8.0sccm, the screen electrode voltage is 1600V, the acceleration voltage is 120V, the cathode discharge current is 10A, t...

Embodiment 2

[0023] Nanocrystalline CrN / Amorphous Si 3 N 4 Preparation of nanocomposite films:

[0024] (1) After the substrate is degreased and polished, put it into acetone and ethanol for ultrasonic cleaning, take it out, dry it with nitrogen, put it in a vacuum chamber, and vacuum it to 5.0×10 -4 Pa;

[0025] (2) Feed N from the source of the magnetic filter cathode 2 / Ar mixed gas, where Ar flow rate is 7.0sccm, N 2 The flow rate is 21.0sccm, and the cathode high-purity Cr target (purity 99.96%) is struck to generate arc discharge. The cathode current is 65A, the source coil current is 0.5A, the magnetic filter coil current is 3.0A, and the outlet coil current is 1.5A to extract the ion beam. Deposit an 80nm thick CrN film on the substrate with a working pressure of 0.2Pa;

[0026] (3) Then the Ar ion beam is generated by the Kaufmann ion gun, the Ar flow rate is 8.0sccm, the screen electrode voltage is 1700V, the accelerating voltage is 120V, the cathode discharge current is 10A...

Embodiment 3

[0029] Nanocrystalline ZrN / Amorphous Si 3 N 4 Preparation of nanocomposite films:

[0030] (1) After the substrate is degreased and polished, put it into acetone and ethanol for ultrasonic cleaning, take it out, dry it with nitrogen, put it in a vacuum chamber, and vacuum it to 5.0×10 -4 Pa;

[0031] (2) Feed N from the source of the magnetic filter cathode 2 / Ar mixed gas, where Ar flow rate is 7.0sccm, N 2 The flow rate is 21.0sccm, and the cathode high-purity Zr target (purity 99.96%) is struck to generate an arc discharge. The cathode current is 70A, the source coil current is 0.5A, the magnetic filter coil current is 3.0A, and the exit coil current is 1.5A to extract the ion beam. Deposit a 100nm thick ZrN film on the substrate, the working pressure is 0.2Pa;

[0032] (3) Then the Ar ion beam is generated by the Kaufman ion gun, the Ar flow rate is 8.0sccm, the screen electrode voltage is 1600V, the acceleration voltage is 120V, the cathode discharge current is 10A, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com