Solid sampling-non-dispersion atomic fluorescence photometer collocating device and analyzing method

A technique of atomic fluorescence spectrometry and solid sampling, applied in fluorescence/phosphorescence, material excitation analysis, preparation of test samples, etc. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

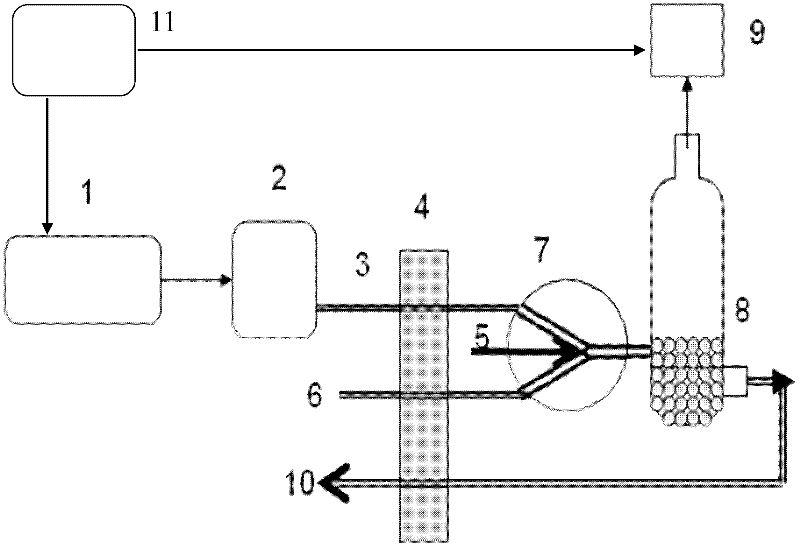

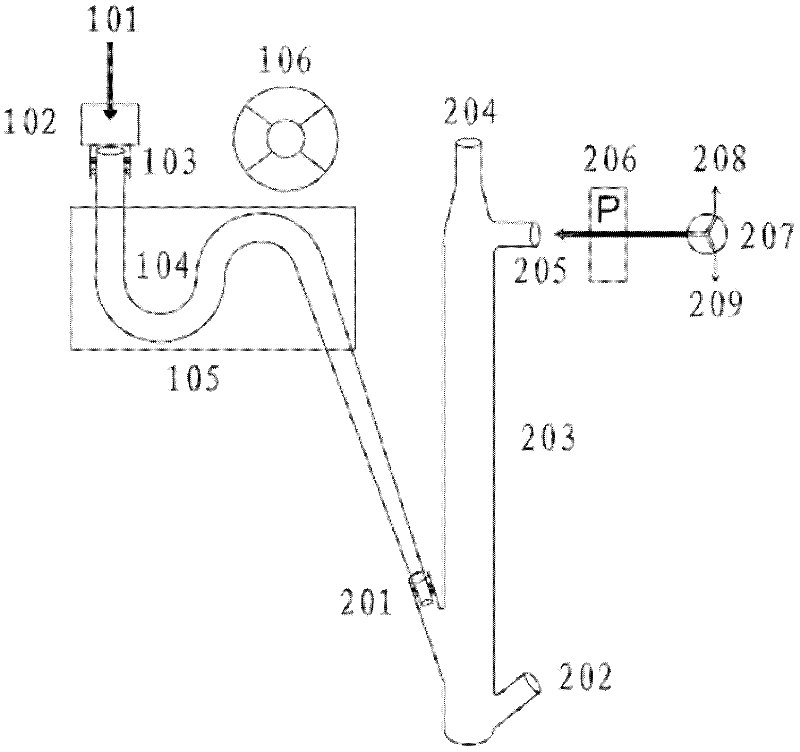

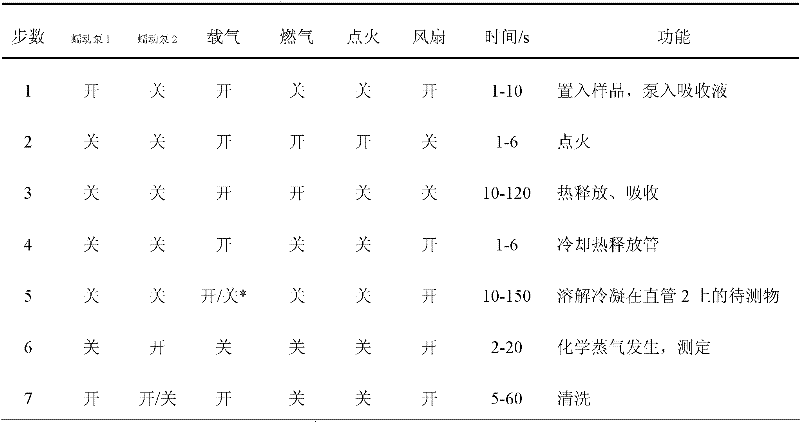

Method used

Image

Examples

Embodiment 1

[0064] Example 1: Analysis of Inorganic Matrix Samples such as Soil and Rocks

[0065] Standard sample analysis data, including 2 rock standard samples (GBW 07104 and GBW07113) and 1 soil standard sample (GBW 07402)

[0066] The first step is to weigh 0.1000g of the selected standard samples respectively, and add 0.200g of thermal release agent ammonium bromide to each sample, mix well and put them into the thermal release tube.

[0067] The second step is to heat and release at 800±50°C. The pyrolysis heating system chooses electric heating wire and liquefied gas-air flame respectively, and the liquefied gas uses a portable liquefied gas compression tank as the gas source.

[0068] The third step, with 5% (v / v) H 2 SO 4 + 1% (m / v) thiourea + 1% (m / v) ascorbic acid mixed solution 5mL is used as the absorption liquid to absorb the released analytical elements.

[0069] The fourth step, with 5% (v / v) H 2 SO 4 + 1% (m / v) thiourea + ascorbic acid mixed solution 5mL is used as...

Embodiment 2

[0080] Embodiment 2: Analysis of organic component samples such as food, plants, and biological samples

[0081] Select GBW10010 (rice), GBW07601 (human hair) and GBW07605 (tea).

[0082] The first step is to weigh 0.1000g of the selected standard samples and put them into the heat release tube.

[0083] The second step is to pass through the argon gas for dry distillation at 800±50°C, and then pass through the sample for dry ashing. During the ashing process, in order to prevent the volatilization loss of Hg, As, Sb and Se, follow-up Gold amalgam trap and absorber tube for absorption. Among them, the heating wire and the liquefied gas-air flame are respectively selected as the adding methods, and the portable liquefied gas compression tank is used as the gas source for the liquefied gas.

[0084] In the third step, 2 mL of a mixed solution of 1% (v / v) HCl + 1% (m / v) thiourea + ascorbic acid was used as the absorption liquid to absorb the released analytical elements.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com