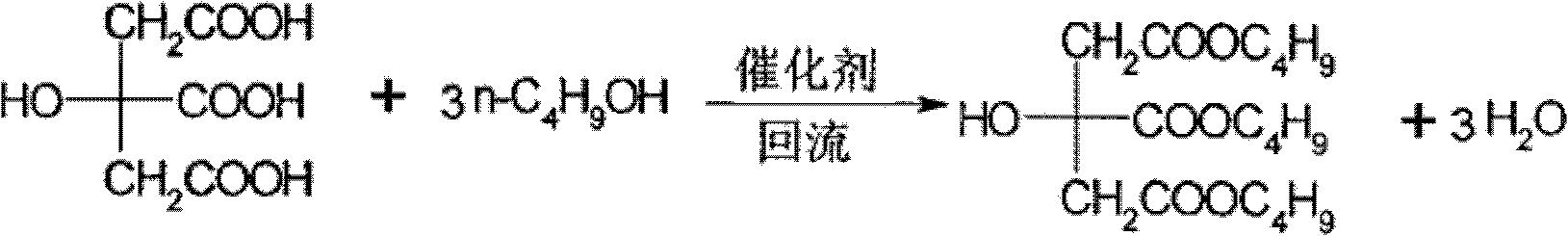

Method for preparing tributyl citrate by using modified cation exchange resin as catalyst

A technology of tributyl citrate and cation exchange, used in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate and other directions, can solve the problems of equipment corrosion, many side reactions, and many by-products, etc., and achieves reaction conditions The effect of mildness, good catalytic effect and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1 Preparation of modified macroporous strongly acidic cation exchange resin

[0025] Convert the sodium-type macroporous (the pore size generally considered in the industry) strongly acidic cation exchange resin to the hydrogen-type by conventional methods, and then dry it at about 80° C. for about 24 hours under vacuum conditions. The dried 3.5g hydrogen-type macroporous strongly acidic cation exchange resin was reacted with 25.2g carbon disulfide and 11.2g anhydrous tin tetrachloride under reflux for about 5 hours. After the reaction was completed, it was poured into water and washed with water until dry Cl - , then washed 3 times with absolute ethanol, and then washed 3 times with acetone, and finally dried the resin at about 70°C for about 24 hours under vacuum conditions to obtain a macroporous strongly acidic cation exchange resin modified with anhydrous tin tetrachloride resin.

[0026] 2 Esterification reaction

[0027] Add 0.2mol monohydrate citric acid, 0.8...

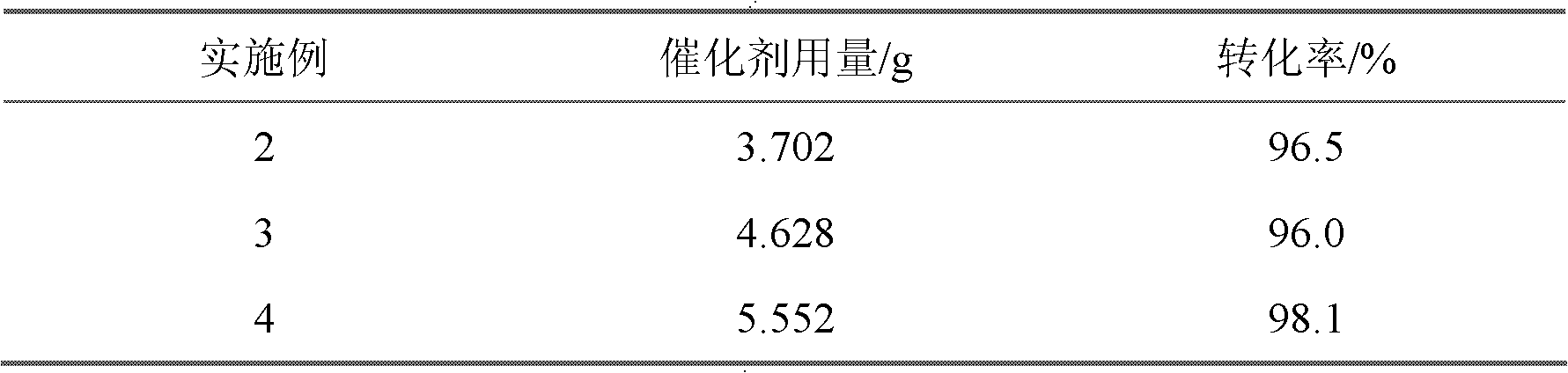

Embodiment 2-4

[0031] Except for the following differences, the others are the same as in Example 1, and the dosage of the modified macroporous strongly acidic cation exchange resin in each example is shown in Table 1 respectively.

[0032] Table 1

[0033]

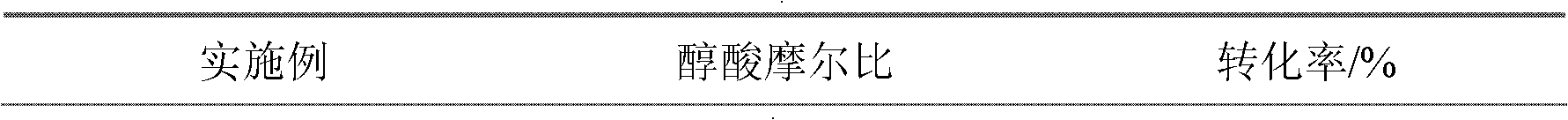

Embodiment 5-7

[0035] Except for the following differences, all the other are the same as Example 1, and the n-butanol consumption of each example is shown in Table 2 respectively.

[0036] Table 2

[0037]

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com