Cotton imitation polyester filament with high hygroscopicity and preparation method thereof

A polyester filament, high moisture absorption technology, applied in the field of polyester modification, can solve the problems of complex modification process, low hydrophilicity of polyester, and high modification cost, achieve excellent anti-mildew and antibacterial properties, simple preparation process, fiber high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

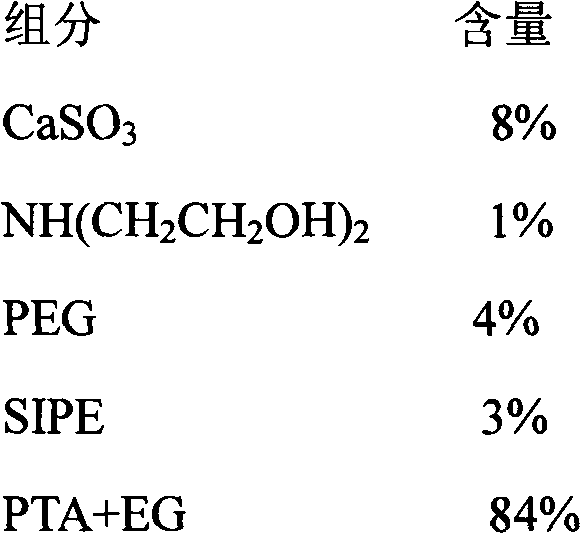

[0029] 1. Preparation of polyester chips: with CaSO 3 , NH(CH 2 CH 2 Oh) 2 , PEG, SIPE, PTA, and EG are raw materials that adopt the method of in-situ polymerization, and the molar material ratio of PTA to EG is 1: 1.25, and carry out in-situ polymerization according to the content of the following raw material components.

[0030]

[0031] Among them, CaSO in the raw material 3 The average diameter of PEG is 10 μm, and the molecular weight of PEG is 4000.

[0032] The in-situ polymerization reaction is divided into esterification and polycondensation process. The esterification reaction is under the protection of nitrogen and the pressure is 0.2MPa. The dibasic acid and dibasic alcohol undergo esterification reaction to form a prepolymer. The reaction temperature is 240°C. Reaction 2h. The polycondensation reaction is carried out pre-condensation at high temperature and normal pressure, the reaction temperature is 260°C, and kept for 1h; then the post-condensation is ...

Embodiment 2

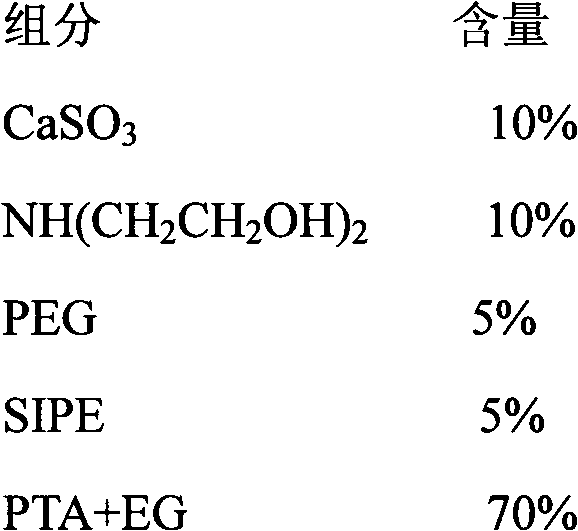

[0037] 1. Preparation of polyester chips: with CaSO 3 , NH(CH 2 CH 2 Oh) 2 , PEG, SIPE, PTA, and EG are raw materials that adopt the method of in-situ polymerization, and the molar material ratio of PTA to EG is 1: 1.30, and the in-situ polymerization is carried out according to the content of the following raw material components.

[0038]

[0039] Among them, CaSO in the raw material 3 The average diameter of PEG is 40 μm, and the molecular weight of PEG is 4000.

[0040] The in-situ polymerization reaction is divided into esterification and polycondensation process. The esterification reaction is under the protection of nitrogen and the pressure is 0.4MPa. The dibasic acid and dibasic alcohol undergo esterification reaction to form a prepolymer. The reaction temperature is 260°C. Reaction 4h. The polycondensation reaction is pre-condensed at high temperature and normal pressure, the reaction temperature is 280°C, and kept for 2h; then the post-condensation is carrie...

Embodiment 3

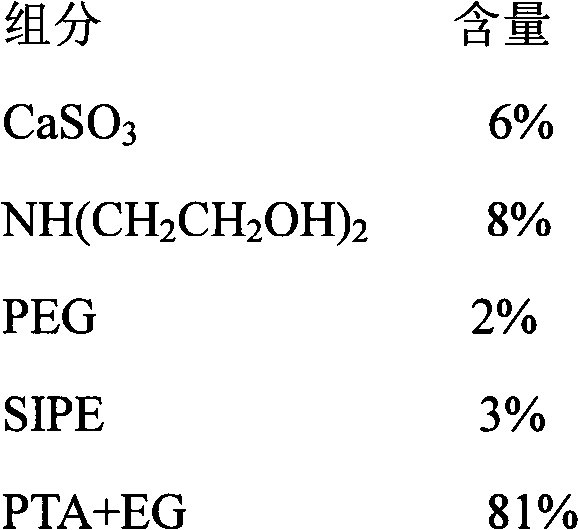

[0045] The preparation of polyester chips is the same as embodiment 1, the preparation of polyester chips: with CaSO 3 , NH(CH 2 CH 2 Oh) 2 , PEG, SIPE, PTA, and EG are raw materials that adopt the method of in-situ polymerization, and the molar material ratio of PTA to EG is 1: 1.05, and the in-situ polymerization is carried out according to the content of the following raw material components.

[0046] The special-shaped spinneret is hollow, wherein the content of raw material components is:

[0047]

[0048] Wherein the average diameter of calcium sulfite in the raw material is 30 μm, and the molecular weight of PEG is 6000.

[0049] The spinning process adopts POY-DTY spinning process, and the process parameters of spinning process:

[0050] Spinning temperature 290°C

[0051]POY spinning speed 4000m / min

[0052] Side blowing temperature 28°C

[0053] Supply air relative humidity 80%

[0054] Wind speed 0.5m / s

[0055] DTY processing speed 800m / min

[0056] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Average diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com