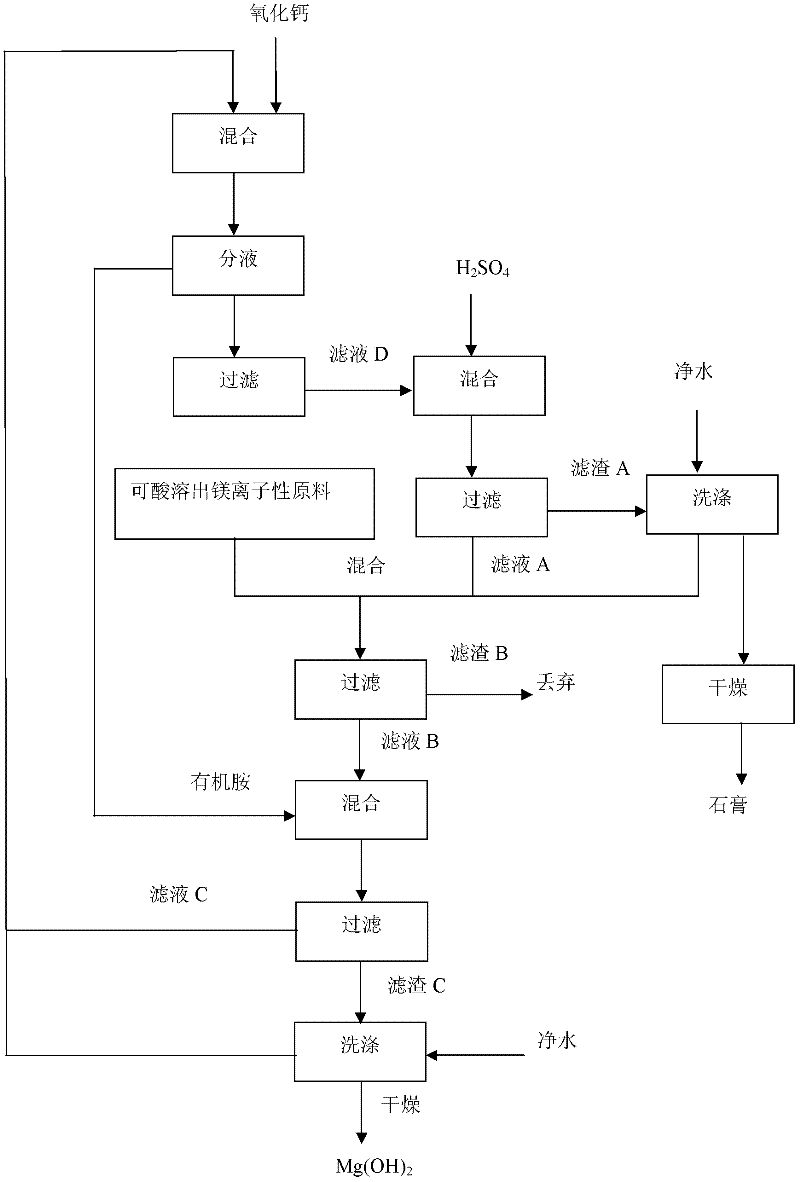

Method for preparing magnesium hydroxide from acid-dissolved magnesium ion-containing raw materials

A technology of magnesium hydroxide and magnesium ions, applied in directions such as magnesium hydroxide, can solve the problems of expensive organic amines, etc., and achieve the effects of low price, low operating cost and easy washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The raw materials used in the present invention include a. 1 part of acid-dissolvable magnesium ionic raw material, which is brucite, and the content of magnesium element in the raw material is measured before use, and the magnesium element is 1mol; b. 1 part of organic amine, which is dinormal Butylamine, 2.0mol of di-n-butylamine; c. 1 part of calcium oxide-containing raw material, measure the effective calcium oxide content in the raw material before use, and the calcium oxide is 1 mol; d. Sulfuric acid, 1 part, measure the sulfate radical content in the raw material before use , the sulfate radical is 1 mol; e. 1 part of calcium chloride is 1 mol. Calcium chloride is used as an initial raw material to start the process cycle and to replenish the loss of chloride ions during the cycle.

[0032] The start-up step of the process cycle of the present invention is firstly preparing calcium chloride into a 1mol / L solution, then slowly adding concentrated sulfuric acid int...

Embodiment 2

[0036] The raw materials used in the present invention include a. 1 part of acid-dissolvable magnesium ionic raw material, which is sorbite, and the content of magnesium element in the raw material is measured before use, and the magnesium element is 1 mol; b. 1 part of organic amine, which is two n-pentylamine, di-n-pentylamine is 2.3mol; c. 1 part of calcium oxide-containing raw material, the effective calcium oxide content in the raw material is measured before use, and the calcium oxide is 1.5 mol; d. sulfuric acid, 1 part, the sulfuric acid in the raw material is measured before use Root content, sulfate root is 1.5mol; e. 1 part of calcium chloride is 1mol. Calcium chloride is used as an initial raw material to start the process cycle and to replenish the loss of chloride ions during the cycle.

[0037] The start-up step of the process cycle of the present invention is firstly preparing calcium chloride into a 4mol / L solution, then slowly adding concentrated sulfuric acid ...

Embodiment 3

[0040] The raw materials used in the present invention include a. 1 part of acid-elutable magnesium ionic raw material, which is magnesite, and the content of magnesium element in the raw material is measured before use, and the magnesium element is 1 mol; b. 1 part of organic amine, which is n-hexylamine , n-hexylamine is 2mol; c. 1 part of calcium oxide-containing raw material, the effective calcium oxide content in the raw material is measured before use, and the calcium oxide is 1.3 mol; d. sulfuric acid, 1 part, the sulfate radical content in the raw material is measured before use, and the sulfate radical is 1.3mol; e. 1 part of calcium chloride is 1mol. Calcium chloride is used as an initial raw material to start the process cycle and to replenish the loss of chloride ions during the cycle.

[0041] The starting step of the process cycle of the present invention is firstly preparing calcium chloride into a 0.1mol / L solution, then slowly adding concentrated sulfuric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com