Cuprous oxide solar battery with surface self-texture structure and manufacturing method thereof

A solar cell, cuprous oxide technology, applied in circuits, electrical components, final product manufacturing, etc., to achieve the effects of abundant raw materials, high photoelectric conversion efficiency, and stable constant current output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

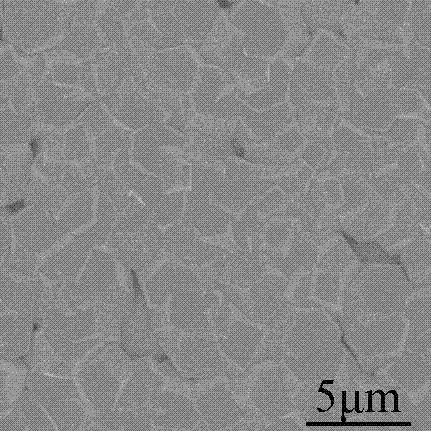

[0034] (1) Growth of n-type cuprous oxide film

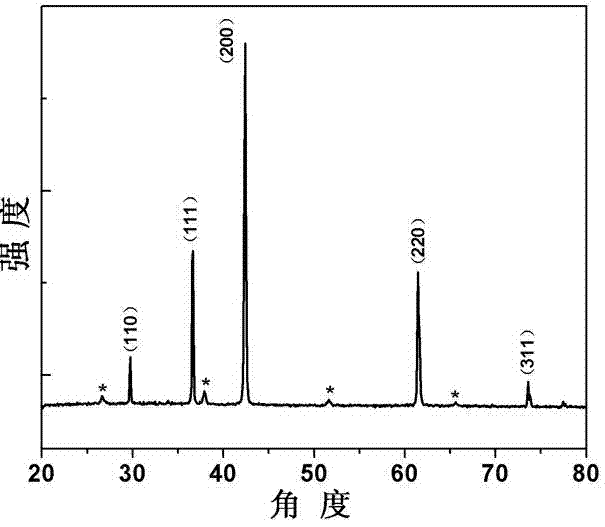

[0035] Put the conductive glass into the electrolytic cell, the electrolyte used is a mixture of copper acetate and acetic acid, the concentration of copper acetate is 0.02mol / l, the concentration of acetic acid is 0.08mol / L, and the concentration is 5mol / L by adding hydrogen Sodium oxide solution adjusts the pH to 4.9, applies a constant voltage of -0.03V, and deposits at 60°C for 60 minutes to prepare an n-type cuprous oxide film with a thickness of 1 μm. The X-ray diffraction pattern is as follows image 3 As shown, it shows that the film has no obvious preferred orientation growth direction;

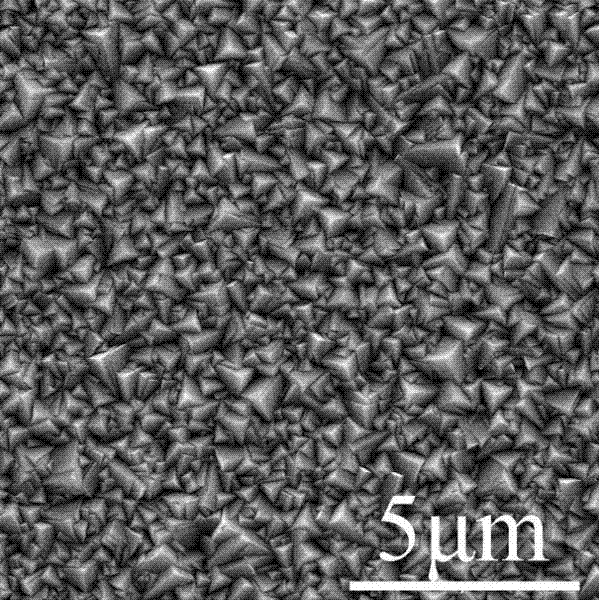

[0036] (2) Growth of p-type cuprous oxide film

[0037] The obtained n-type cuprous oxide film is put into an electrolytic cell, and the electrolytic solution used is a mixed solution of copper sulfate and lactic acid, the concentration of copper sulfate is 0.4mol / L, and the concentration of lactic acid is 5mol / L, and the concentr...

Embodiment 2

[0043] (1) Growth of n-type cuprous oxide film

[0044] Cut the FTO transparent conductive glass into 1×4 cm substrates, then ultrasonically clean with photobleaching detergent for 30-60min, alcohol ultrasonically for 30-60min, then ultrasonically clean with distilled water for 10-30min, and finally put into the drying box Drying; put the dried substrate into the electrolytic cell, the electrolyte used is a mixture of copper acetate and acetic acid, the concentration of copper acetate is 0.02mol / L, the concentration of acetic acid is 0.04mol / L, adjust the pH value to 4, apply -0.1V constant voltage, deposited at 40°C for 30 min, prepared n-type cuprous oxide film with a thickness of 0.1 μm, and its X-ray diffraction pattern was the same as image 3 similar, indicating that the film has no obvious preferred orientation growth direction;

[0045] (2) Growth of p-type cuprous oxide film

[0046]Put the obtained n-type cuprous oxide film into the electrolytic cell, the elect...

Embodiment 3

[0051] (1) Growth of n-type cuprous oxide film

[0052] Clean the conductive glass ultrasonically with photobleaching detergent for 30-60 minutes, ultrasonically clean alcohol for 30-60 minutes, then ultrasonically clean it with distilled water for 10-30 minutes, and finally put it into a drying oven to dry, and then put it into an electrolytic cell. It is a mixture of copper acetate and acetic acid, the concentration of copper acetate is 0.015mol / L, the concentration of acetic acid is 0.06mol / L, and the pH value is adjusted to 4.5 by adding a sodium hydroxide solution with a concentration of 3mol / L dropwise, and -0.01V is applied Constant voltage, deposited at 50°C for 45min, prepared n-type cuprous oxide film with a thickness of 0.6μm, and its X-ray diffraction pattern was the same as image 3 similar, indicating that the film has no obvious preferred orientation growth direction;

[0053] (2) Growth of p-type cuprous oxide film

[0054] The obtained n-type cuprous oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com