Polyphenyl ether alloy and preparation method thereof

A technology of polyphenylene ether and polyphenylene ether resin, which is applied in the field of polyphenylene ether alloy and its preparation, can solve the problem of damage to the mechanical properties of polyphenylene ether, heat resistance, dimensional stability, weather resistance, electrical insulation, and blending modification Problems such as large material content, to achieve the effect of good mechanical properties, good dimensional stability and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

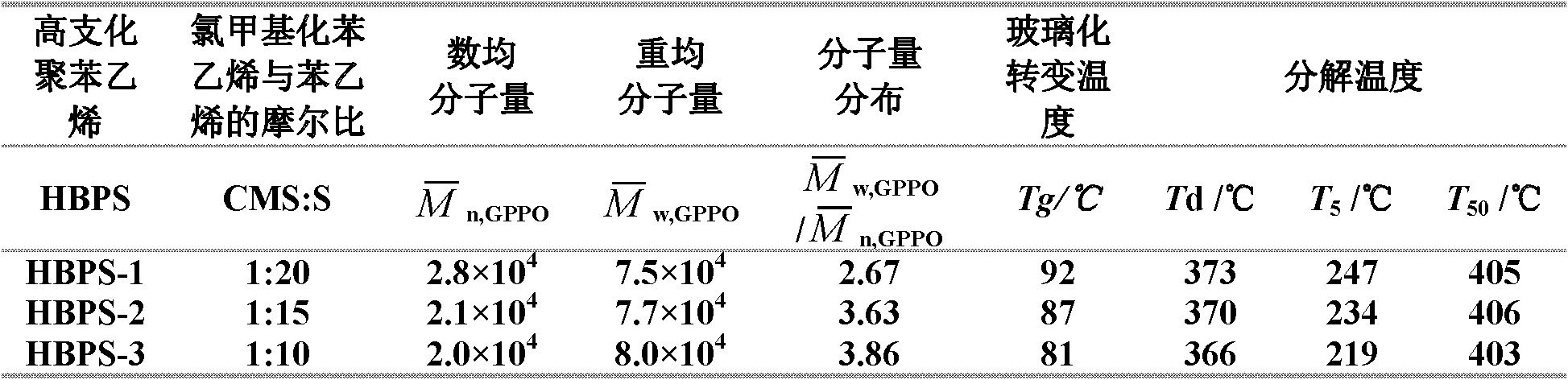

[0045] The synthesis of embodiment 1 hyperbranched polystyrene

[0046] Wash the chloromethylated styrene with 5% sodium hydroxide and distilled water three times successively, and then dry with anhydrous sodium sulfate; distill the styrene under reduced pressure; wash the cuprous chloride with glacial acetic acid and methanol respectively, and vacuum dry. In three 250ml round bottom flasks, add chloromethylated styrene, styrene, cuprous chloride and 2.2′-bipyridine in sequence in different proportions, and place them in a constant temperature oil bath at 130°C under nitrogen protection. Internal polymerization, after the reaction, dissolve with butanone, then settle in ethanol, filter with suction, and dry to obtain three kinds of hyperbranched polystyrene, HBPS-1, HBPS-2, HBPS-3, chloromethylated benzene The molar ratios of ethylene and styrene are 1:20, 1:15, and 1:10, respectively.

[0047] Gel permeation chromatography (GPC) was used to measure molecular weight and mole...

Embodiment 2

[0050] The blending preparation of embodiment 2 polyphenylene ether and hyperbranched polystyrene

[0051] The polyphenylene ether alloy components of this embodiment are: 3kg PPO, 45g HBPS-2, 6g tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester (referred to as antioxidant 1010), 6g tris(2,4-di-tert-butylphenyl) phosphite (abbreviated as antioxidant 168), 9g lubricant zinc stearate.

[0052] Wherein the viscosity of polyphenylene ether resin is 0.55Pa s, Japan Asahi Kasei Company; The mol ratio of chloromethylated styrene and styrene in hyperbranched polystyrene HBPS-2 is 1: 15, is synthesized by laboratory; Oxidant 1010, antioxidant 168, BASF, Germany; lubricant calcium stearate, Jiangsu Tyrek Chemical Co., Ltd.

[0053] The synthesized powdery HBPS-2 was dried in a vacuum drying room at 90°C for 8 hours. Using the melt blending method, add dry PPO into the internal mixer, banbury at 280°C for 10 minutes, then add dry HBPS-2, antioxidant 1010,...

Embodiment 3

[0055] The blending preparation of embodiment 3 polyphenylene ether and hyperbranched polystyrene

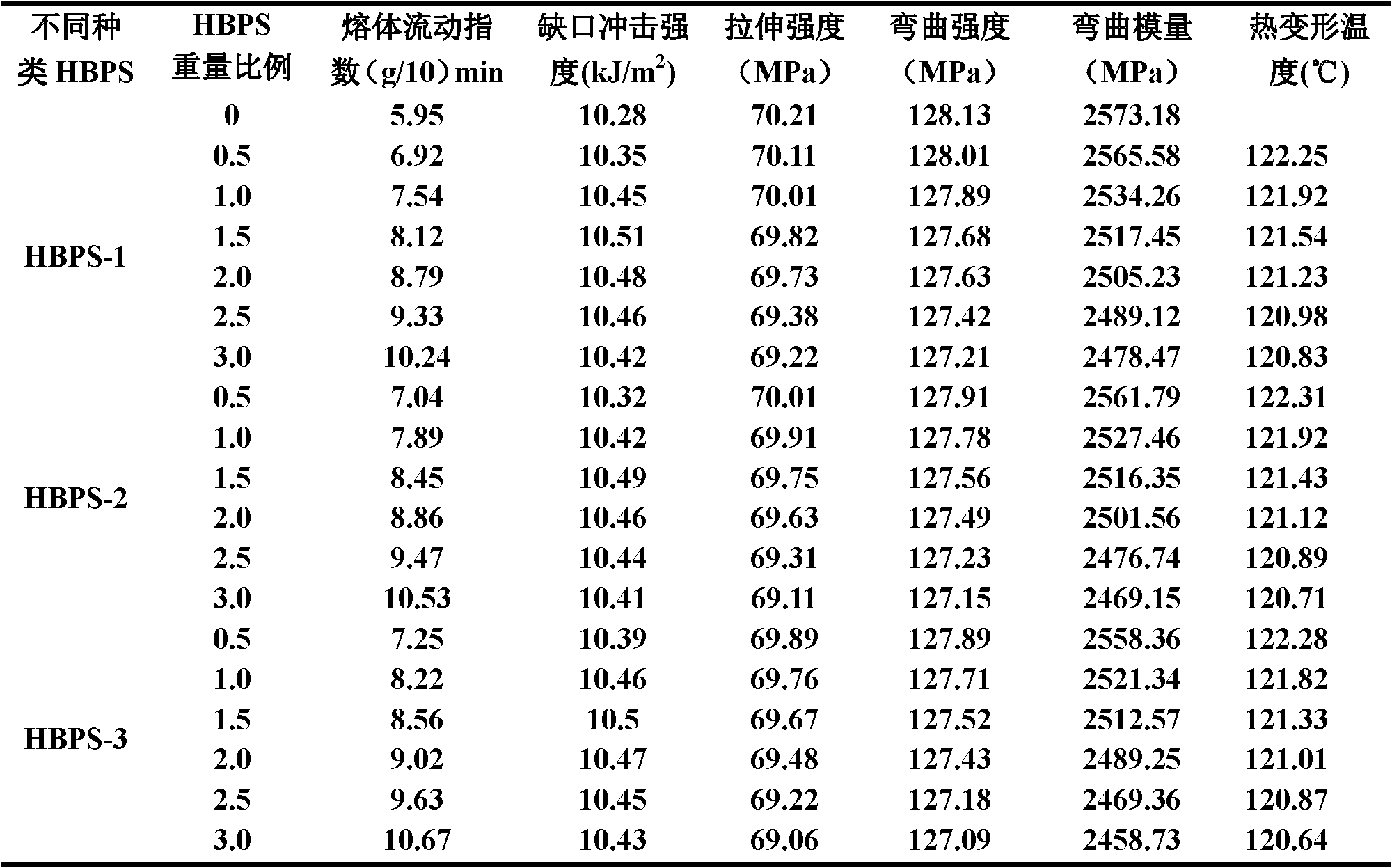

[0056] The synthesized powdered HBPS-1, HBPS-2, and HBPS-3 were dried in a vacuum drying room at 90°C for 8 hours. Using the melt blending method, add the dry PPO into the internal mixer, banbury at 260 ° C for 10 minutes, and then dry the HBPS-1, HBPS-2, and HBPS-3 at 0.5, 1.0, 1.5, 2.0, and 2.5 , 3.0% by weight, and 0.2% antioxidant 1010, 0.2% antioxidant 168, and 0.3% lubricant calcium stearate were added to PPO, mixed for 5 minutes, discharged, and granulated to obtain 18 kinds of polyphenylene ether alloys. The blended and granulated pellets were injection molded to obtain notched impact, tensile, bending, and thermal deformation temperature specimens for mechanical and thermal performance tests; the pellets were used to measure the melt flow index. After testing, the properties of the polyphenylene ether alloy are shown in Table 2.

[0057] Table 2 Performance data of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com