Silicon nano wire based sensor having selective fluorescence response on nitric oxide

A silicon nanowire, nitric oxide technology, applied in the field of fluorescent chemical sensors, can solve problems such as hydrolysis, difficult synthesis, easy photobleaching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

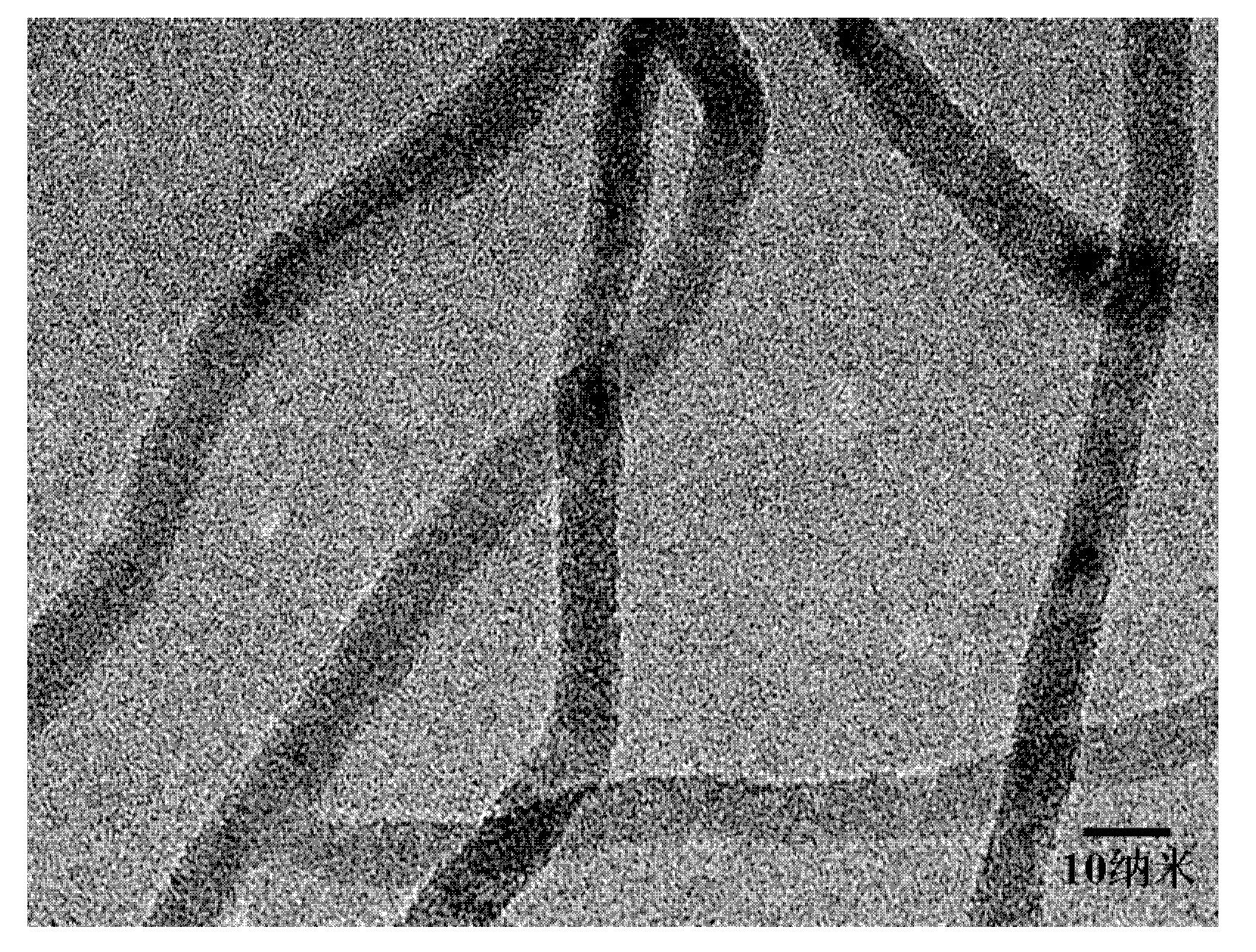

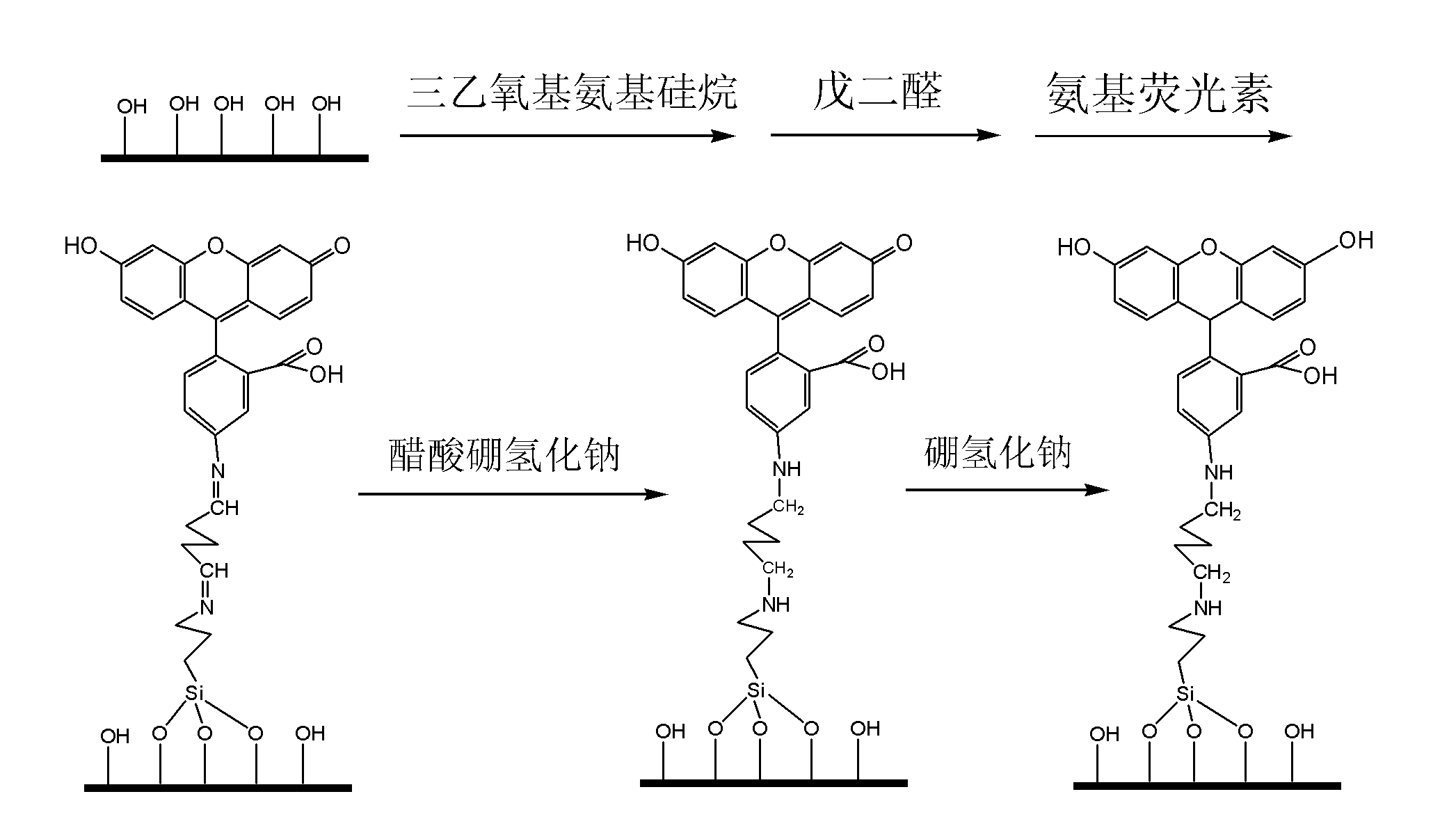

[0036] 1) At room temperature, grind the silicon monoxide in a mortar and put it in a porcelain boat, and place the porcelain boat in the middle of the quartz tube. Before heating, the system is vacuumed to 10 with a mechanical pump and a molecular pump. -3 Pa, followed by a flow rate of 25 sccm (mL / min) into the mixed gas of argon (accounting for 95% of the mixed gas volume) and hydrogen (accounting for 5% of the mixed gas volume), when the pressure is stable at 10 3 At Pa, the system began to heat up. The system rises to 300°C at 10°C / min, and then to 800°C at 20°C / min. At this time, close the gas valve and pump gate, keep it for 10 minutes and continue to heat up to 1350°C, react at 1350°C for 5 hours, and the reaction is over After that, cool to room temperature naturally, and collect the products on both sides of the porcelain boat. The silicon nanowires obtained are single crystal silicon wires with a diameter of 15-20 nm in the center and a layer of amorphous silicon oxide...

Embodiment 2

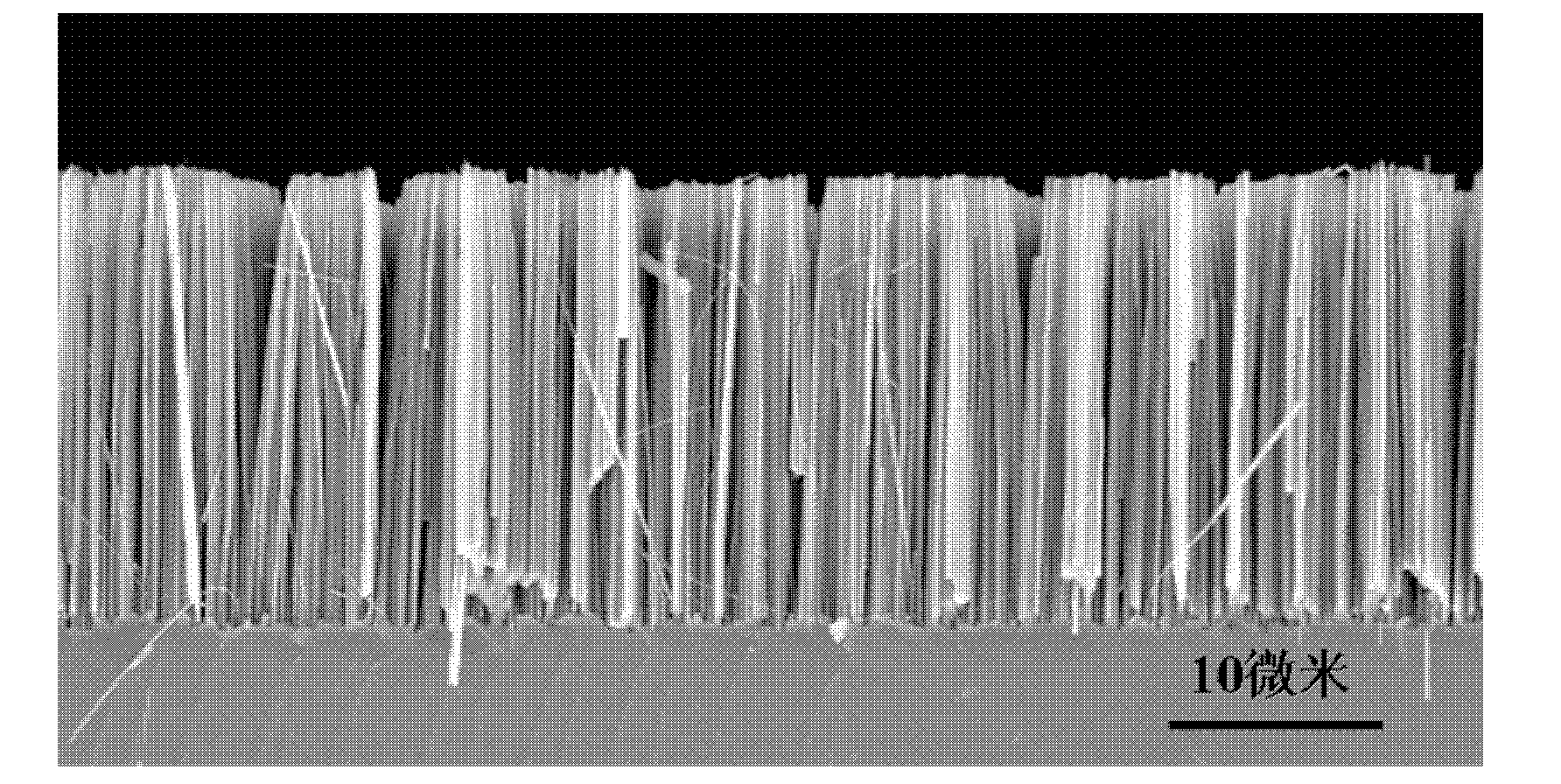

[0047] 1) Take a 2cm×0.5cm (100) silicon wafer and clean it with ethanol, acetone, and distilled water for 10 minutes; then soak the silicon wafer in an HF aqueous solution with a mass concentration of 5% for 15 minutes; After taking it out, put it in a concentration of 5mmol / L AgNO 3 And 4.8mol / L HF mixed aqueous solution; after soaking for 2.5 minutes, take it out and put it into 10mL containing 4.8mol / L HF and 0.2mol / LH 2 O 2 In the mixed aqueous solution, the system is kept in a water bath at 50°C; after 35 minutes, the silicon wafers are taken out and placed in a mixed solution containing 4.5 mL of concentrated hydrochloric acid (mass concentration of 36%) and 1.5 mL of concentrated nitric acid (mass concentration of 36%); After soaking for 1 hour, take out the silicon wafer, rinse it with distilled water, and place it in a watch glass to dry naturally to obtain a silicon nanowire array composed of silicon nanowires. The silicon nanowires have a diameter of 100-200nm and a l...

Embodiment 3

[0056] 1) At room temperature, grind the silicon monoxide in a mortar and put it in the porcelain boat, and place the porcelain boat in the middle of the quartz tube. Before heating, the system will be vacuumed to 10 with a mechanical pump and a molecular pump. -3 Pa, followed by a flow rate of 25 sccm (mL / min) into the mixed gas of argon (accounting for 95% of the mixed gas volume) and hydrogen (accounting for 5% of the mixed gas volume), when the pressure is stable at 10 3 At Pa, the system began to heat up. The system rises to 300°C at 20°C / min and then to 800°C at 10°C / min. At this time, close the gas valve and pump gate, keep it for 10 minutes and continue to heat up to 1350°C, react at 1350°C for 5 hours, and the reaction is over After that, it is naturally cooled to room temperature, and the products are collected on both sides of the porcelain boat. The silicon nanowires obtained are single crystal silicon wires with a central diameter of 5-15 nm and a layer of amorphous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com