Method for preparing silicon dioxide mesoporous spheres with adjustable pore sizes and particle sizes

A technology of silica and mesoporous spheres, applied in the direction of silica, silica, etc., to achieve good biocompatibility, wide application prospects, good drug loading and release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

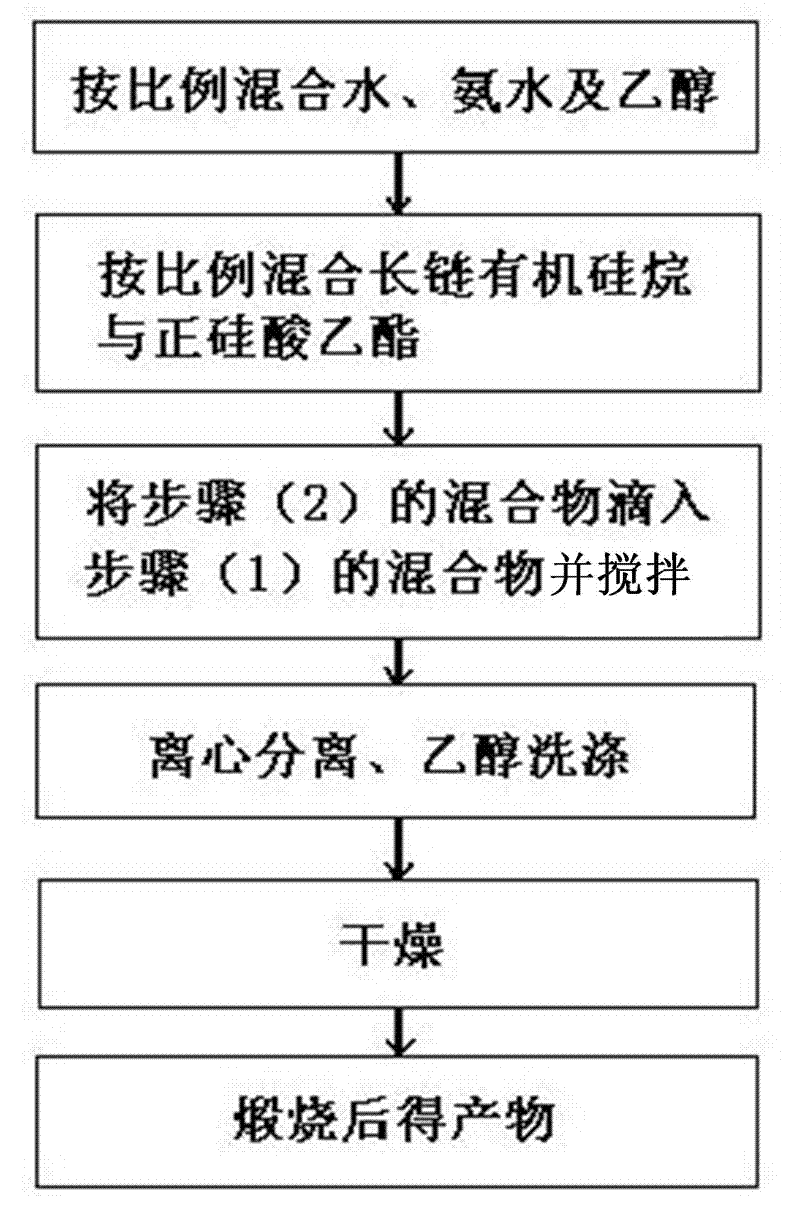

[0044] See attached figure 1 . A method for preparing silica mesoporous spheres with adjustable pore size, the steps comprising:

[0045] (1) First mix deionized water, ammonia water and absolute ethanol according to the molar ratio of 1:0.15:0.7;

[0046] (2) long-chain organosilane (C 18 TMS) was mixed with tetraethyl orthosilicate (TEOS) at a molar ratio of 1:4.5;

[0047] (3) Add the mixture of ethyl orthosilicate and long-chain organosilane in step (2) to the mixed solution in step (1) dropwise according to the molar ratio of water to silicon: 1: 0.0041, and stir at room temperature for 4 hours;

[0048] (4) centrifuging the product obtained in step (3), and washing the obtained white product 3 times with ethanol;

[0049] (5) Dry the white product after washing with ethanol in step (4) at 80°C for 12 hours ;

[0050] (6) Finally, calcining the white product at a high temperature of 550° C. for 6 hours to obtain the aforementioned silica mesoporous spheres with adjust...

Embodiment 2

[0053] Implementation step is basically the same as embodiment 1, the difference is:

[0054] (1) Reduce the amount of ethanol so that the molar ratio of deionized water to absolute ethanol is 1:3.9;

[0055] (2) Mix long-chain organosilane and ethyl orthosilicate at a molar ratio of 1:5.0;

[0056] (5) The white product washed with ethanol in step (4) was dried at 100° C. for 8 hours.

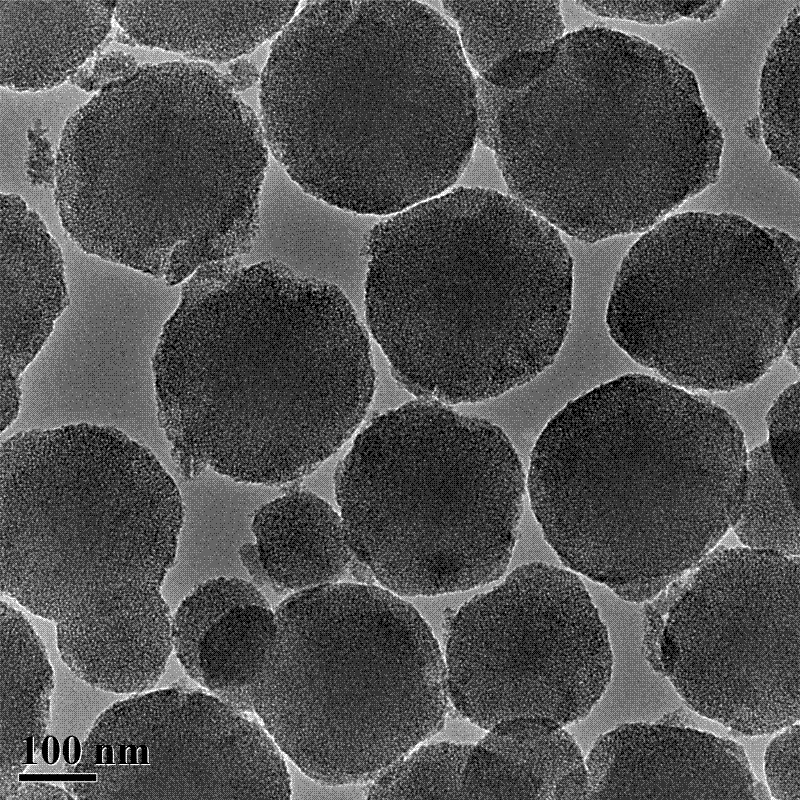

[0057] For the transmission electron microscope photo of the silica mesoporous spheres prepared in Example 2, see image 3 .

[0058] The comparison results of the specific surface area, pore volume and pore diameter of the silica mesoporous spheres prepared in Examples 1 and 2 are shown in Table 1.

[0059] Table 1. Comparison results of specific surface area, pore volume and pore diameter of silica mesoporous spheres

[0060] .

Embodiment 3

[0062] Implementation content is basically the same as embodiment 2, the difference is:

[0063] Reduce the amount of silicon source added to make the molar ratio of water to silicon 1:0.00125.

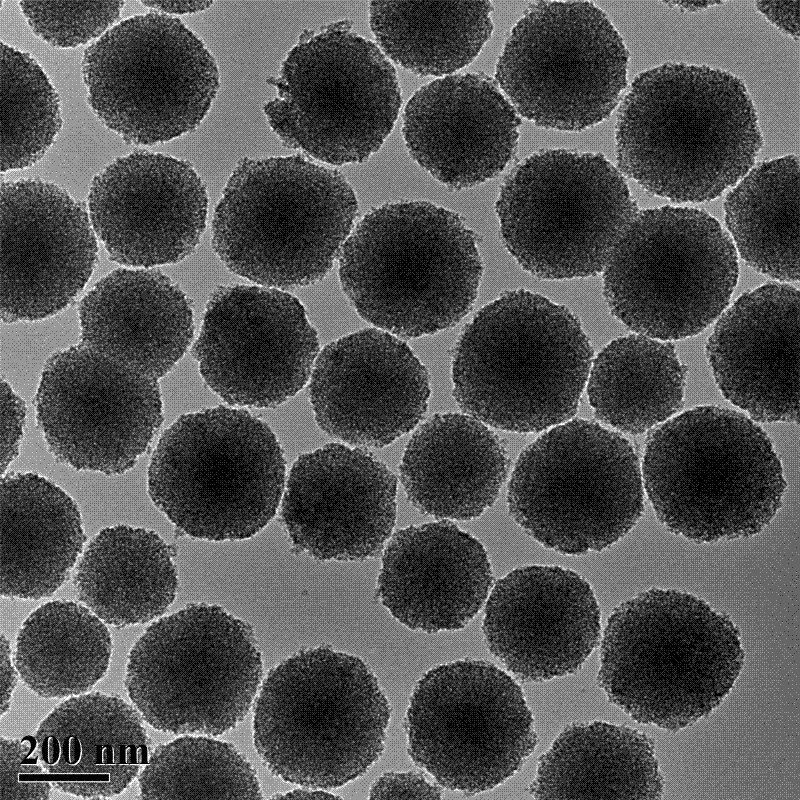

[0064] The transmission electron micrograph of the silica mesoporous sphere prepared in embodiment 3 is shown in Figure 4 .

[0065] For comparison of the nitrogen adsorption-desorption results before and after loading doxorubicin on the silica mesoporous spheres prepared in Example 3, see Figure 7 ;

[0066] The sustained release curves of the silica mesoporous spheres loaded with doxorubicin prepared in Example 3 under different acidity conditions are shown in Figure 8 .

[0067] The effect of silica mesoporous spheres prepared in Example 3 on the survival rate of mouse fibroblast L929 is shown in Figure 9 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com