Water-based working liquid for electrical discharge wire cutting and preparation method thereof

An EDM wire and working fluid technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of blackening of the workpiece surface, high-cost market usage, reducing the surface quality of workpiece machining, and achieve low manufacturing cost, easy biological Degradable, inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the wire electric discharge cutting water-based working fluid is carried out according to the following steps:

[0026] (1) Add the triethanolamine measured according to the proportion into the reaction pot and heat it to 80°C±3°C;

[0027] (2) Add the measured powdered boric acid, stir for 8 minutes to 12 minutes and wait for it to dissolve;

[0028] (3) Heat up to 120°C±3°C, and react under this temperature condition for 100 minutes to 140 minutes;

[0029] (4) Cool down to 80°C±3°C, add measured amount of oleic acid and react for 50-70 minutes;

[0030] (5) Cool down to 60°C±3°C;

[0031] (6) Combine the barium petroleum sulfonate dissolved in sodium benzoate in advance with the measured amount of sodium petroleum sulfonate, sodium dodecylsulfonate, nonylphenol polyoxyethylene ether OP-10, Span S-80, fat Alcohol polyoxyethylene ether MOA-15 and sodium fatty alcohol polyoxyethylene etherate AES are mixed together with the remaining water...

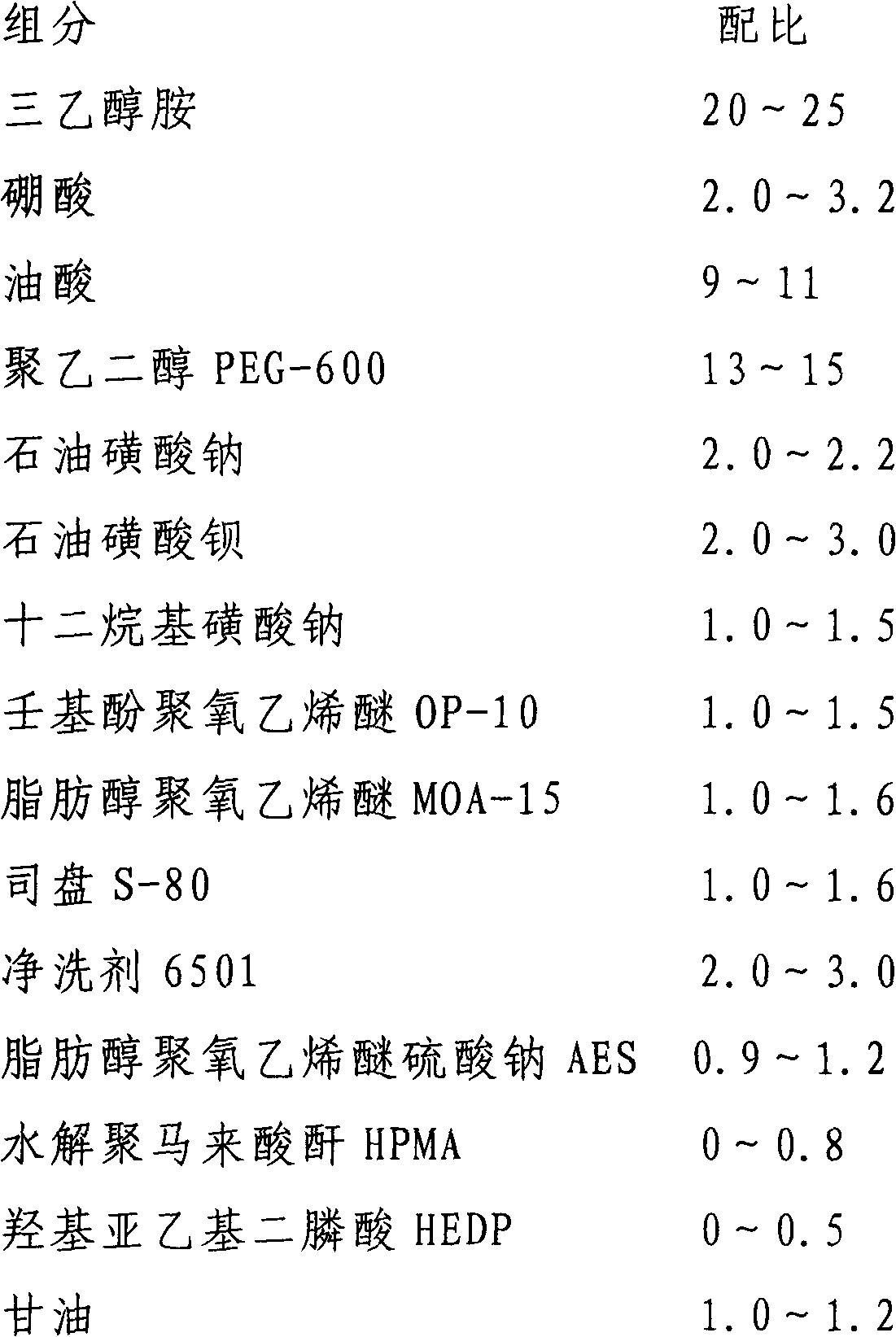

Embodiment 1~3

[0034] Examples 1-2 are used in hard water areas, and the components contain hydrolyzed polymaleic anhydride HPMA and hydroxyethylene diphosphonic acid HEDP anti-hard water dispersant. Use CaO to measure the water hardness used, the water hardness in Example 1 is 85 mg / L, and the water hardness in Example 2 is 120 mg / L. The water hardness of Example 3 is 80 mg / L, which belongs to soft water, so hydrolyzed polymaleic anhydride HPMA and hydroxyethylene diphosphonic acid HEDP are omitted from the components. The specific components and proportions of Examples 1-3 are shown in Table 1 below, and the specific process conditions of the preparation method are shown in Table 2.

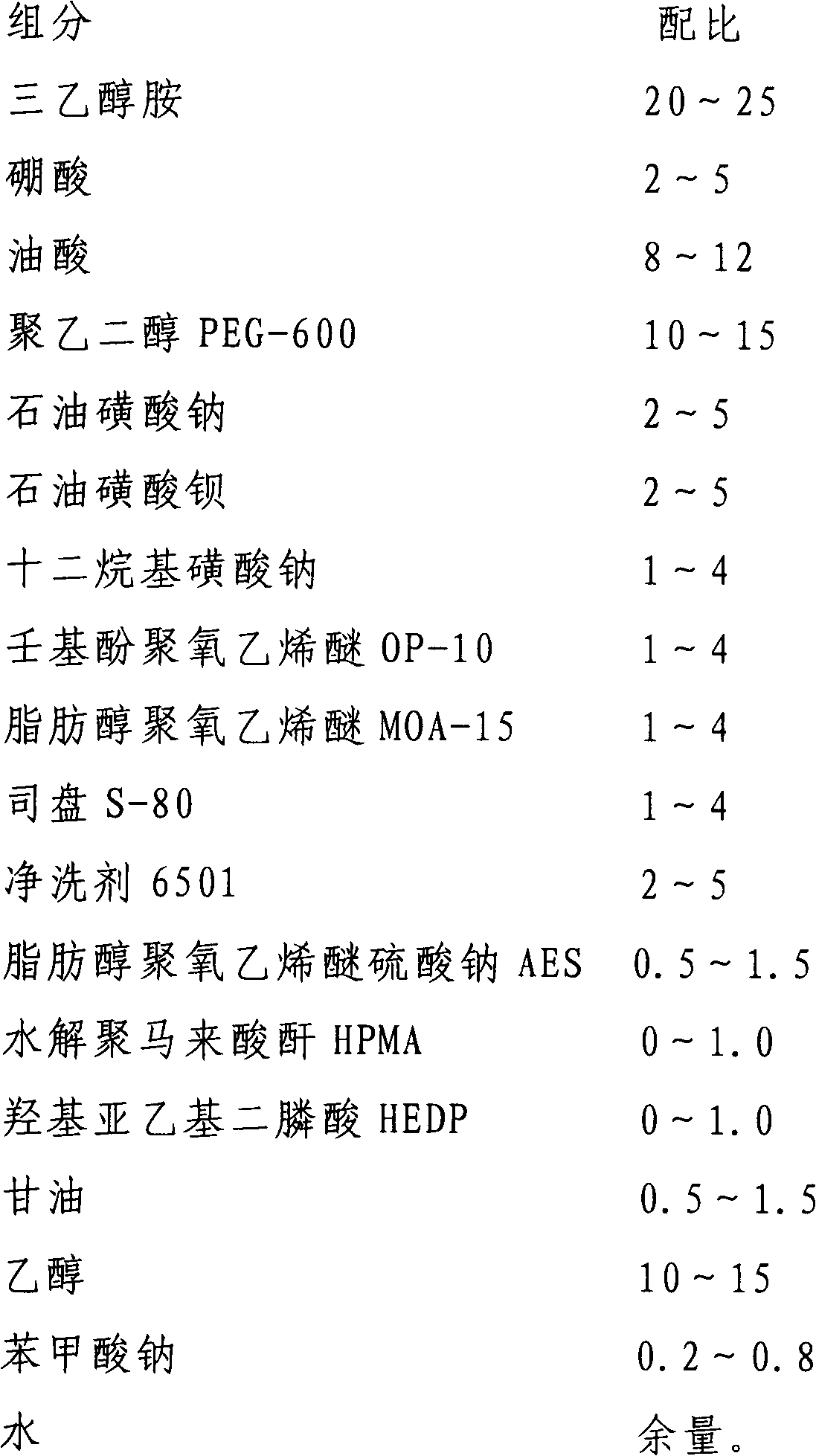

[0035] Table 1: Specific components and proportioning tables of Examples 1 to 3

[0036]

Embodiment 1

[0039] The products of Examples 1 to 3 are all in yellowish transparent liquid, the pH value of Example 1 is 7.5; the pH value of Example 2 is 8.2; the pH value of Example 3 is 7.8. The products of Examples 1 to 3 are all diluted with water, and after dilution, they can be used for cooling in turning, grinding, milling and sawing in addition to being used for cooling in wire electric discharge cutting. Both the components of Example 1 and Example 2 contain anti-hard water dispersants, which can be directly diluted with local water in areas with relatively hard water quality, instead of using deionized water. This effect is not only convenient for use in hard water areas, but also saves costs , the most important thing is to use it in hard water areas to avoid blackening of the workpiece processing surface, no burns, no pits, no pitting. The components of the invention do not contain mineral oil or vegetable oil, are non-toxic, have no irritating odor, are easy to biodegrade, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com