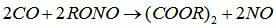

Catalyst used for gas-phase synthesis of oxalate ester and its preparation method

A gas-phase synthesis and catalyst technology, applied in the fields of carbon monoxide or formate reaction preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high price, high catalyst cost, influence on use, etc., and achieve a low amount of precious metals. , the effect of low catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 10 grams of α-Al 2 o 3 Support, according to 0.01wt%Cu +1.0wt%Mo+0.5wt%Pd / α-Al 2 o 3 content to prepare the catalyst, the steps are as follows: take the calculated amount of copper nitrate and ammonium molybdate dissolved in water to form a solution, the specific surface area is 5.0 m 2 / g of α-Al 2 o 3 The carrier was soaked in the prepared impregnating solution for 4 hours, filtered, dried at room temperature, put into a reaction vessel, added an appropriate amount of water, and added dropwise 1mol / L K 2 CO 3Aqueous solution, adjust the dropping speed to ensure that the pH value of the solution in the reaction vessel is around 9; after the dropping is completed, age for 6 hours; filter, wash, dry, and roast at 500°C for 2 hours to obtain Cu / Mo / α-Al 2 o 3 Precursor; weigh the calculated amount of palladium chloride to make a solution, impregnate Cu / Mo / α-Al 2 o 3 Precursor, let it stand for 6 hours; filter, put it into the reaction container after drying ...

Embodiment 2

[0040] Weigh 10 grams of α-Al 2 o 3 Support, according to 1.0wt%Cu+0.01wt%Fe+0.3wt%Pd / α-Al 2 o 3 Content preparation catalyst, its steps are as follows: take calculated amount of copper nitrate and ferric nitrate dissolved in water to make a solution, the specific surface area is 10.0 m 2 / g of α-Al 2 o 3 The carrier is soaked in the prepared impregnation solution for 5 hours, filtered, dried at room temperature, put into a reaction vessel, and an appropriate amount of water is added, and a KOH aqueous solution with a concentration of 1mol / L is added dropwise in a 50°C water bath and stirred. , adjust the rate of addition to ensure that the pH of the solution in the reaction vessel is around 9; after the addition is completed, age for 2 hours; filter, wash, dry, and roast at 300 ° C for 5 hours to obtain Cu / Fe / α-Al 2 o 3 Precursor; weigh the calculated amount of palladium nitrate to make a solution, impregnate Cu / Fe / α-Al 2 o 3 The precursor was left to stand for 4 hour...

Embodiment 3

[0043] Weigh 10 grams of α-Al 2 o 3 Support, according to 0.3wt%Cu +0.9wt%Zn +0.4wt%Pd / α-Al 2 o 3 Content preparation catalyst, its steps are as follows: take calculated amount of copper nitrate and zinc nitrate dissolved in water to make a solution, the specific surface area is 30.0 m 2 / g of α-Al 2 o 3 The carrier was soaked in the prepared impregnation solution for 6 hours, filtered, dried at room temperature, put into the reaction vessel, added an appropriate amount of water, and added dropwise Na 2 CO 3 Aqueous solution, adjust the dropping speed to ensure that the pH value of the solution in the reaction vessel is around 10; after the dropping is completed, age for 6 hours; filter, wash, dry, and roast at 400°C for 4 hours to obtain Cu / Zn / α-Al 2 o 3 Precursor; Weigh the calculated amount of palladium acetate to make a solution, impregnate Cu / Zn / α-Al 2 o 3 The precursor was left to stand for 2 hours; filtered, dried at room temperature, put into a reaction vessel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com