Fermentation-separation coupling biological hydrogen-producing method for improving hydrogen-producing fermentation efficiency

A biohydrogen production and efficiency technology, applied in separation methods, fermentation, and dispersed particle separation, can solve problems such as hydrogen production rate decline, metabolic stagnation, and harmful system microorganisms, so as to improve substrate utilization and hydrogen production capacity , the effect of flexible operation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

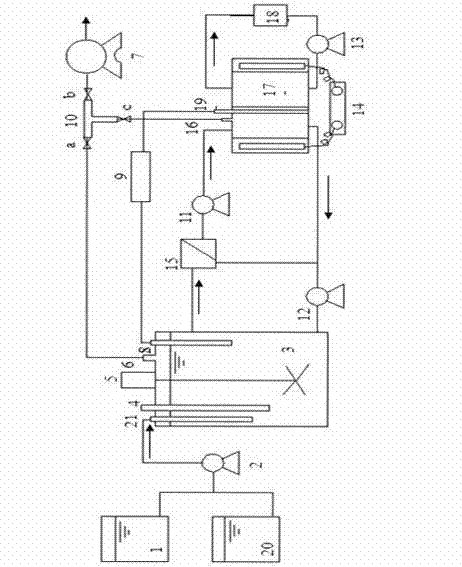

Image

Examples

Embodiment 1

[0011] 1. Prepare liquid medium for biohydrogen production and place it in container 1 for use. Liquid medium (g / L): glucose 10; tryptone 4; beef extract 2; yeast juice 1; NaC1 4; K 2 HPO 4 1.5; MgC1 6H 2 O 0.1; FeSO 4 ·7H 2 O 0.08; L-cysteine 0.5; vitamin solution 10 mL; trace element solution 10 mL; resazurin (0.2%) 0.5 mL. Vitamin solution (g / L): cobalamin 0.01; ascorbic acid 0.025; riboflavin 0.025; citric acid 0.02; pyridoxal 0.05; folic acid 0.01; p-aminobenzoic acid 0.01; Trace element solution (g / L): MnSO 4 ·7H 2 O 0.01; ZnSO4 7H2O 0.05; H 3 BO 3 0.01; N(CH 2 COOH) 3 4.5; CaC1 2 2H 2 O 0.01; Na 2 MoO 4 0.01; CoC1 2 ·6H 2 O 0.2; AlK(SO 4 ) 2 12H 2 O 0.01.

[0012] 2. Open the three-way ventilation valve 10, fill nitrogen gas from the sampling port 4 and sampling port 16 for 5~10 minutes, close the valve c of the ventilation valve 10, and close the sampling port 16. The liquid medium in container 1 was fed into anaerobic fermentation reactor 3 ...

Embodiment 2

[0017] 1. 2.3.4. Same as embodiment 1.

[0018] 5. liquid level controller 21 starts water inlet pump 2, pumps high-concentration liquid medium into reactor 3 from medium storage tank 20, and high-concentration liquid medium substance concentration is 10 times of liquid medium in embodiment 1, Restore the liquid level of the reactor to the initial value, that is, the volume of the reaction liquid reaches 1.2L. Under the action of the mixer 5, the high-concentration medium and the separated fermentation liquid are completely mixed for hydrogen production fermentation, and the generated gas passes through the gas outlet 6 and the gas flow rate After counting 7, it was collected and separated to obtain hydrogen.

[0019] 6. Repeat step 3.4.5.6.

[0020] In the fermentation-separation coupled biological hydrogen production method in the present invention, the specific hydrogen production rate is 2.54mol H under the feeding operation mode. 2 / mol glucose, compared with the tradit...

Embodiment 3

[0022] 1. Prepare simulated organic wastewater (similar in nature to sugar factory wastewater) and place it in container 1 for use. The preparation process is as follows, add 10~15mL of waste molasses to 1L of tap water, the chemical oxygen demand concentration of the organic wastewater is 8g / L, add 5~10 grains of chemical fertilizers, so that the chemical oxygen demand: N:P=500~1000 :5:1.

[0023] 2. Open the three-way ventilation valve 10, fill nitrogen gas from the sampling port 4 and sampling port 16 for 5~20 minutes, close the valve c of the ventilation valve 10, and close the sampling port 16. The simulated organic wastewater in container 1 was fed into anaerobic fermentation reactor 3 (stirred tank reactor) through feed pump 2, with a total volume of 3.8L and a reaction zone volume of 2.5L. The temperature of the reactor was controlled at 35±1°C. Add anaerobic fermentation hydrogen-producing bacteria to the reactor 3 to make its initial concentration reach 2g / L, close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com