Double-acceptor co-doping method for growing p-(K-N):ZnO thin film

A co-doping and acceptor technology, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., to achieve the effect of increasing concentration, avoiding interstitial defects, good repeatability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

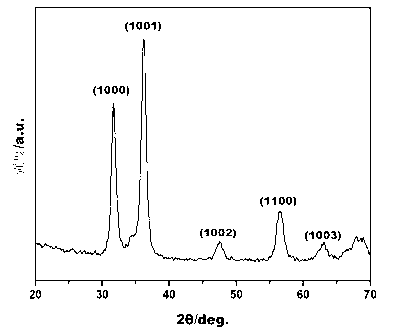

Image

Examples

Embodiment 1

[0024] 1000 grams of ZnO powder with a purity of 99.99% and 1 gram of a purity of 99.99% K 2 O powder was ball-milled and mixed in a ball mill for 12 hours, and then pre-fired at 600°C for 6 hours. After grinding into a powder, 30 grams of polyvinyl alcohol with a purity of 99.99% was added to form a precursor powder;

[0025] Press the precursor powder into a disc with a diameter of 76.2 mm and a thickness of 5 mm, and sinter at 1200 ° C for 4 hours to obtain a K:ZnO disc, which is used as a target for magnetron sputtering;

[0026] Put the prepared K:ZnO target material and the single crystal sapphire substrate after cleaning the surface into the vacuum chamber of the radio frequency magnetron sputtering device respectively, the distance between the target material and the substrate is 5cm, and the The substrate is completely blocked, the vacuum chamber is evacuated, and the substrate is heated to 450°C at the same time;

[0027] When the vacuum degree in the vacuum chamber...

Embodiment 2

[0032] 100 grams of ZnO powder with a purity of 99.995% and 1 gram of a purity of 99.995% K 2 O powder was ball milled and mixed in a ball mill for 8 hours, then pre-fired at 1000°C for 2 hours, and after being ground into a powder, 5 grams of polyvinyl alcohol with a purity of 99.995% was added to form a precursor powder;

[0033] Press the precursor powder into a disc with a diameter of 25.4 mm and a thickness of 3 mm, and sinter at 1500 ° C for 1 hour to obtain a K:ZnO disc, which is used as a target for magnetron sputtering;

[0034] Put the prepared K:ZnO target material and the single crystal sapphire substrate after cleaning the surface into the vacuum chamber of the radio frequency magnetron sputtering device respectively, the distance between the target material and the substrate is 4cm, and the The substrate is completely blocked, the vacuum chamber is evacuated, and the substrate is heated to 650°C at the same time;

[0035] When the vacuum degree in the vacuum cha...

Embodiment 3

[0040]1000 grams of ZnO powder with a purity of 99.998% and 5 grams of a purity of 99.998% K 2 O powder was ball milled and mixed in a ball mill for 15 hours, then pre-fired at 800°C for 4 hours, and after grinding into a powder, 40 grams of polyvinyl alcohol with a purity of 99.998% was added to form a precursor powder;

[0041] Press the precursor powder into a disk with a diameter of 76.2mm and a thickness of 5mm, and sinter at 1300°C for 3 hours to obtain a K:ZnO disk, which is used as a target for magnetron sputtering;

[0042] Put the prepared K:ZnO target material and the single crystal sapphire substrate after cleaning the surface into the vacuum chamber of the radio frequency magnetron sputtering device respectively, the distance between the target material and the substrate is 6cm, and the The substrate is completely blocked, the vacuum chamber is evacuated, and the substrate is heated to 500°C at the same time;

[0043] When the vacuum degree in the vacuum chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com