Preparation and application of lithium-rich laminar metal oxide as negative electrode material of lithium ion cell

A negative electrode material, a technology of vanadium oxide, applied in battery electrodes, vanadium compounds, circuits, etc., can solve the problems of lowering battery voltage and limiting applications, and achieves the effects of high specific energy, uniform shape, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

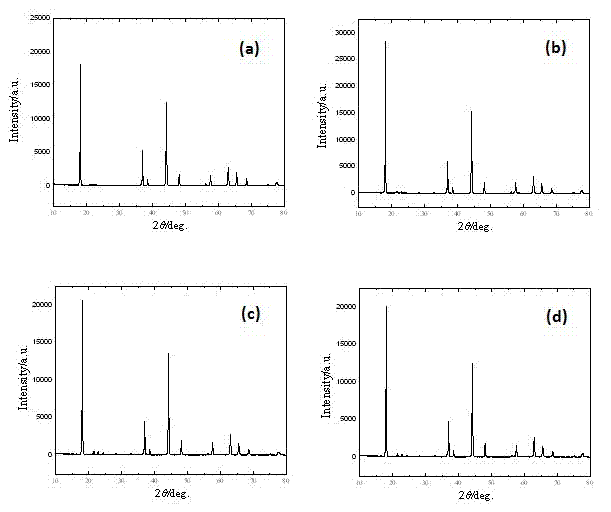

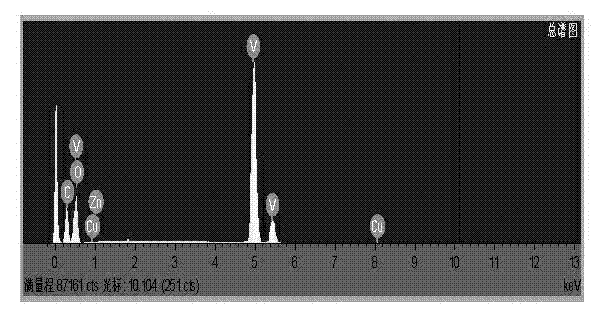

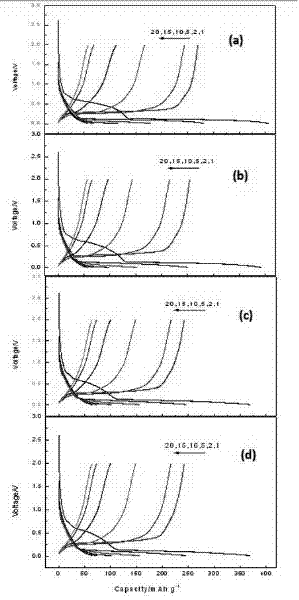

[0030] Weigh 3.8235 grams of vanadium trioxide and 2.2167 grams of lithium carbonate powder respectively, dissolve in 300 mL of distilled water, then slowly add 12.06 grams of adipic acid powder, at 80 o Magnetically stirred at C, and evaporated to dryness at constant temperature (the molar ratio of vanadium trioxide: lithium carbonate: adipic acid is 1:1.20:2). Transfer the evaporated mixture to a corundum ark, move it into a tube furnace, and pass it into a protective atmosphere Ar / H 2 (95:5 vol / vol%) mixed gas. First, let it stand under a protective atmosphere for 2 hours, then raise the temperature to 1000°C at a rate of 1°C / min, and keep it for 8 hours, and then cool down to room temperature at a rate of 1°C / min. A sample was taken out and ground in a mortar to obtain a black powder product. Do XRD, SEM and XPS analysis of the obtained products respectively, such as figure 1 (a), figure 2 (a), Figure 4 (a), indicating that the product is Li 1+x VO 2 . After the ...

Embodiment 2

[0033] Weigh 3.8235 grams of vanadium trioxide and 2.2536 grams of lithium carbonate powder respectively, dissolve them in 300 mL of distilled water, then slowly add 12.06 grams of adipic acid powder, at 80 o Magnetically stirred at C, and evaporated to dryness at constant temperature (the molar ratio of vanadium trioxide: lithium carbonate: adipic acid is 1:1.22:2). Transfer the evaporated mixture to a corundum ark, move it into a tube furnace, and pass it into a protective atmosphere Ar / H 2(95:5 vol / vol%) mixed gas. First, let it stand under a protective atmosphere for 2 hours, then raise the temperature to 1000°C at a rate of 10°C / min, and keep it for 12 hours, and then cool down to room temperature at a rate of 10°C / min. A sample was taken out and ground in a mortar to obtain a black powder product. Do XRD, SEM and XPS analysis of the obtained products respectively, such as figure 1 (b), figure 2 (b), Figure 4 (b), indicating that the product is Li 1+x VO 2 , Ther...

Embodiment 3

[0036] Weigh 3.8235 grams of vanadium trioxide and 2.2167 grams of lithium carbonate powder respectively, dissolve in 300 mL of distilled water, then slowly add 12.06 grams of adipic acid powder, at 80 o Magnetically stirred at C, and evaporated to dryness at constant temperature (the molar ratio of vanadium trioxide: lithium carbonate: adipic acid is 1:1.18:2). Transfer the evaporated mixture to a corundum ark, move it into a tube furnace, and pass it into a protective atmosphere Ar / H 2 (95:5 vol / vol%) mixed gas. First stand in a protective atmosphere for 2 hours, then raise the temperature to 800°C at a rate of 5°C / min, and keep it for 24 hours, and then cool down to room temperature at a rate of 30°C / min. A sample was taken out and ground in a mortar to obtain a black powder product. Do XRD, SEM and XPS analysis of the obtained products respectively, such as figure 1 (c), figure 2 (c), Figure 4 (c), indicating that the product is Li 1+x VO 2 .

[0037] With the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com