Rare-earth perovskite type catalyst for treating industrial waste gas as well as preparation method and application thereof

A technology of industrial waste gas and rare earth calcium, which is applied in the field of air pollution control technology and environmental protection catalytic materials, can solve the problems of poor catalytic combustion effect of VOCs, poor general practical performance, and poor anti-toxin ability, so as to facilitate the expansion of reproduction and active temperature window Wide, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

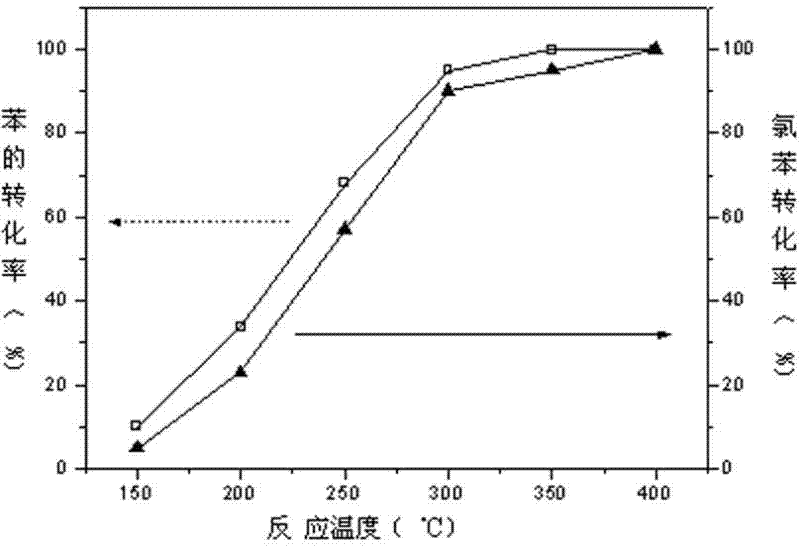

Examples

Embodiment 1

[0035] (1) Preparation of self-made cordierite carrier

[0036] Take 30g of silicon oxide, 40g of aluminum oxide and 30g of magnesium oxide and mix evenly. The mixture is put into a muffle furnace and roasted at 1300°C. Boil and keep warm on electric furnace for 2 h, drying temperature is 80°C, drying time is 2 h, then put into muffle furnace for roasting at 400°C, keep warm for 6h and then cool in furnace to obtain self-made cordierite carrier;

[0037] (2) Preparation of active component impregnation solution

[0038] First prepare the aqueous solution of lanthanum oxalate, calcium nitrate, cobalt oxalate, and manganese oxalate, then add the complexing agent citric acid solution, and heat it in a constant temperature water bath at 90°C until the water sol is obtained, which is the impregnation solution; the final concentration of La and Ca in the impregnation solution The molar ratio is 0.1:0.9, and the molar ratio of B-site elements Co and Mn is 0.3:0.7, that is, La 0.1 ...

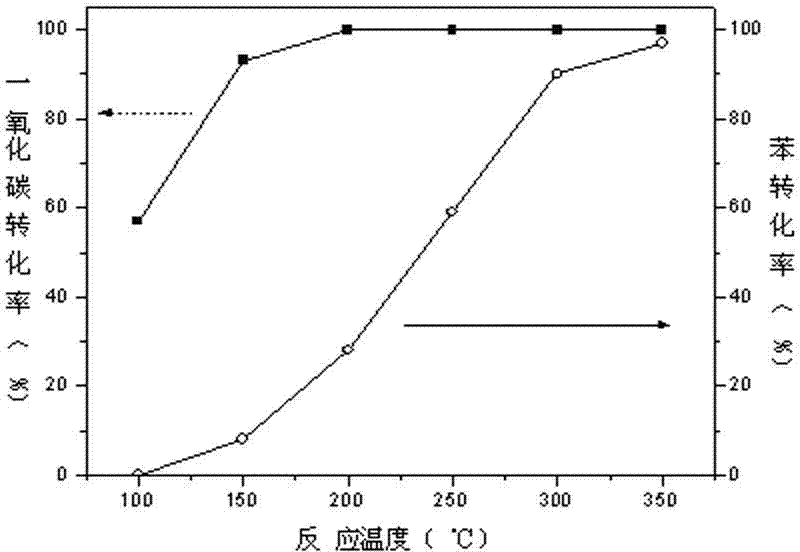

Embodiment 2

[0043] (1) Preparation of self-made cordierite carrier

[0044] Take 40g of silicon oxide, 30g of aluminum oxide and 30g of magnesium oxide and mix evenly. The mixture is put into a muffle furnace and roasted at 1400°C. Boil in an electric furnace and hold for 2 h, dry at 80°C, and dry for 2 h, then bake in a muffle furnace at 400°C, hold for 6 h and then cool in the furnace to obtain a self-made cordierite carrier;

[0045] (2) Preparation of active component impregnation solution

[0046] First prepare the aqueous solution of lanthanum nitrate, barium nitrate, cobalt nitrate, and ferric nitrate, then add the complexing agent ammonium citrate solution, and heat it in a constant temperature water bath at 90°C until the water sol is obtained, which is the impregnating liquid; the final impregnating liquid La, Ba The molar ratio of Co and Fe is 0.3:0.7, and the molar ratio of Co and Fe is 0.1:0.9, that is, La 0.3 Ba 0.7 co 0.1 Fe 0.9 o 3 . The molar ratio of La, Ba total ...

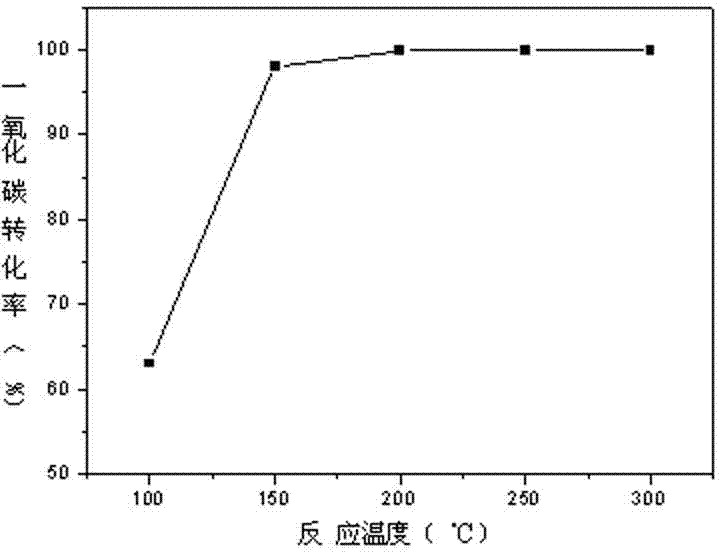

Embodiment 3

[0051] (1) Preparation of self-made cordierite carrier

[0052] Take 55g of silicon oxide, 20g of aluminum oxide and 25g of magnesium oxide and mix evenly. The mixture is put into a muffle furnace, roasted at 1400 ° C, kept for 4 hours, cooled in the furnace, and then modified by an acetic acid solution with a mass concentration of 20%. Boil in an electric furnace and hold for 3 h, dry at 120°C, and dry for 1 h; put it into a muffle furnace for calcination at 600°C, hold for 4 h and cool in the furnace to obtain a self-made cordierite carrier;

[0053] (2) Preparation of active component impregnation solution

[0054] First prepare the aqueous solution of lanthanum acetate, calcium nitrate, cobalt acetate and nickel acetate, then add the complexing agent citric acid solution, heat in a 90°C constant temperature water bath until the water sol is obtained, which is the impregnation solution; the final concentration of La and Ca in the impregnation solution The molar ratio is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com