Water dispersible environmentally-friendly nanometer structure automotive finish paint and preparation method thereof

An environment-friendly, nano-structured technology, applied in biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., can solve the problem of large polymer emulsion particle size, poor paint film compactness, and gaps in protection and decoration effects It can achieve the effect of low surface tension, enhanced adhesion and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 50% of Nanopolymer Emulsion 1, 0.2% of wetting agent, 0.6% of dispersant, 0.02% of defoamer, 0.3% of pH regulator, 0.15% of preservative, 0.15% of antifungal agent and 10.58% deionized water were added into the paint mixing tank, and dispersed for 10 minutes at a disperser speed of 400-800 rpm. Then add 15% titanium dioxide, 10% black iron oxide, 4% mica powder, 4% barium sulfate, 0.5% zinc phosphate, and disperse for 15 minutes at a disperser speed of 800 rpm. Then use a sand mill to grind to a fineness of less than 60 μm. Add 3% drier according to the recipe, stir at 800 rpm for 5 minutes, and finally add 1.5% thickener to adjust the viscosity to pass, filter and pack with a 100-mesh filter.

Embodiment 6

[0040] Weigh 60% of Nanopolymer Emulsion 2, 0.2% of wetting agent, 0.4% of dispersant, 0.02% of defoamer, 0.2% of pH regulator, 0.1% of preservative, 0.05% of antifungal agent and 10.78% deionized water were added into the paint mixing tank, and dispersed for 10 minutes at a disperser speed of 400-800 rpm. Then add 10% titanium dioxide, 5% black iron oxide, 2% talcum powder, 5% mica powder, 3% barium sulfate, 0.25% zinc phosphate, and disperse at a disperser speed of 800 rpm 15 minutes. Then use a sand mill to grind to a fineness of less than 60 μm. Add 2% drier according to the formula, stir at 800 rpm for 5 minutes, finally add 1% thickener, adjust the viscosity to pass, filter with 100-mesh filter, and pack.

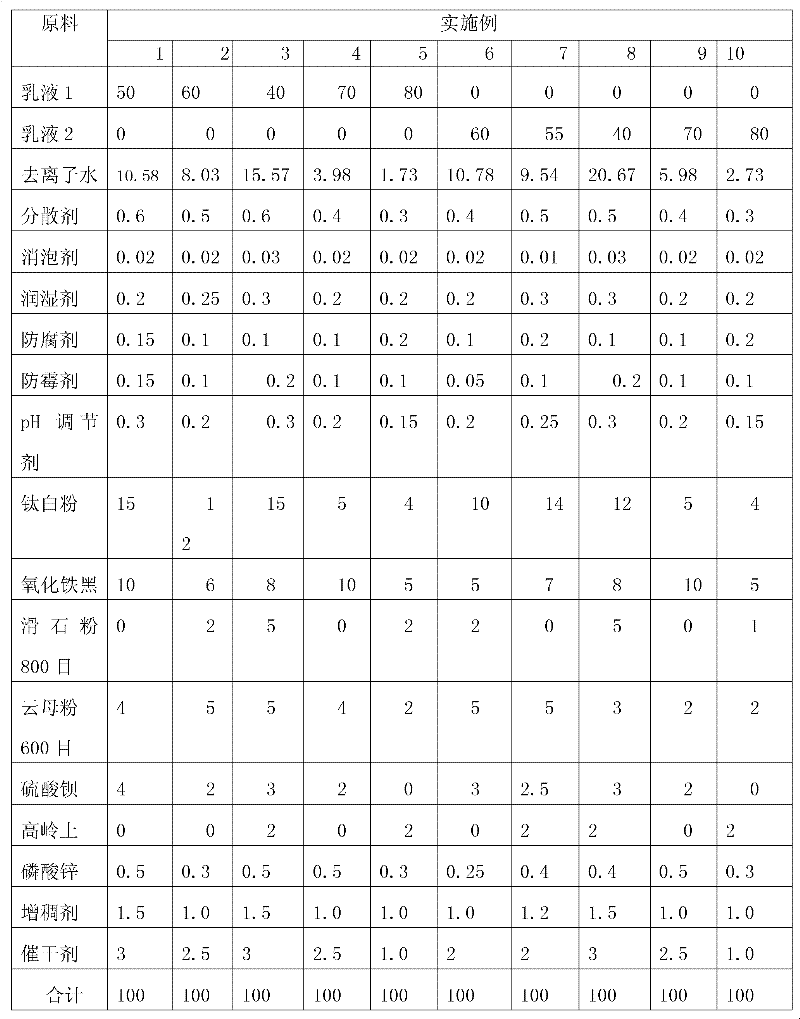

[0041] Table 1: Component composition embodiment 1-10 of the present invention

[0042]

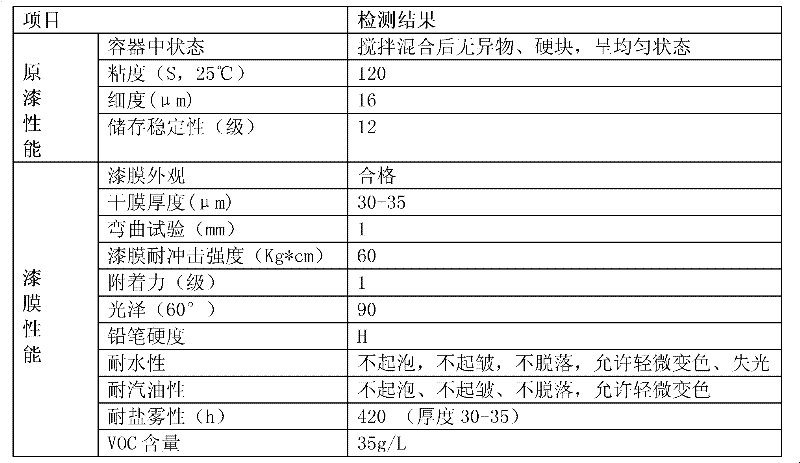

[0043] Table 2: Performance indicators of water-dispersed and environmentally friendly nanostructured automotive topcoats prepared by formulation

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com