Method for producing antibacterial peptide by using brevibacillus laterosporu

A technology of Bacillus lateralis and Bacillus brevis, applied in the field of biological fermentation, can solve the problems of few reports on antimicrobial peptides, poor heat resistance, and narrow antibacterial spectrum, achieve broad-spectrum antibacterial activity, good heat resistance, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 antimicrobial peptide

[0035] 1. Preparation of seed solution

[0036] Inoculate Brevibacillus laterosporus AS1.2738 into the sterilized seed culture medium and culture it at 30°C for 16 hours to obtain a seed solution with a bacterial content of 10 8 cfu / ml.

[0037] The preparation of the seed medium is as follows: yeast extract 5g, peptone 10g, sodium chloride 5g, distilled water 1000ml, pH 7.3;

[0038] 2. Preparation of antimicrobial peptides by fermentation

[0039] The seed solution obtained in step 1) was inoculated into the fermentation medium according to the volume ratio of the inoculation amount 2% to carry out fermentation culture, culture conditions: 32 ° C, shaker speed 180r / min, fermentation culture 18h,

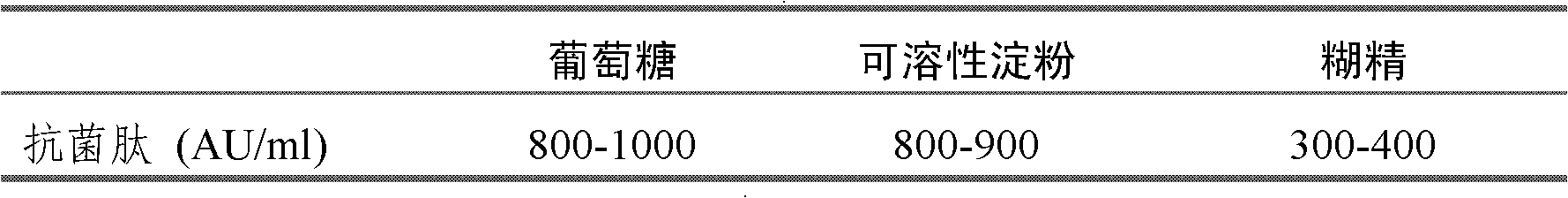

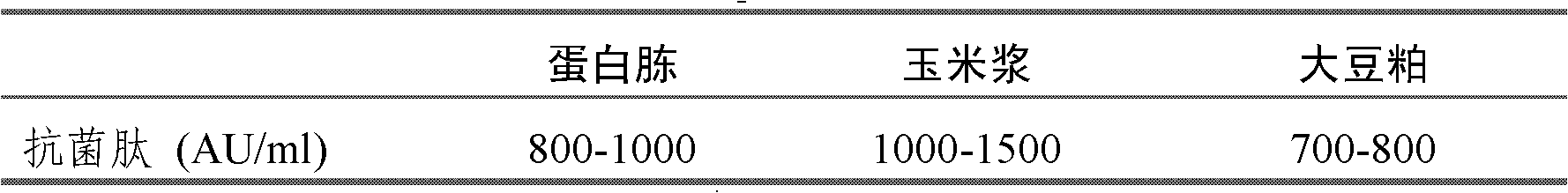

[0040] The fermentation medium contains 3.5% of carbon source, 3% of nitrogen source and 0.2% of inorganic salt, all in mass-volume ratio.

Embodiment 2

[0041] The preparation of embodiment 2 antimicrobial peptides

[0042] 1. Preparation of seed solution

[0043] Inoculate Brevibacillus laterosporus AS1.2739 into the sterilized seed culture medium and culture it at 37°C for 12 hours to obtain a seed solution with a bacterial content of 10 7 cfu / ml.

[0044] The preparation of the seed medium is as follows: beef extract 10g, peptone 20g, sodium chloride 7g, distilled water 1000ml, pH 7.2;

[0045]2. Preparation of antimicrobial peptides by fermentation

[0046] The seed solution obtained in step 1) was inoculated into the fermentation medium according to the volume ratio of the inoculation amount of 2% to carry out fermentation culture, culture conditions: 35 ° C, shaking table speed 280r / min, fermentation culture 16h,

[0047] The fermentation medium contains 0.5% of carbon source, 0.5% of nitrogen source and 0.005% of inorganic salt, all in mass-volume ratio.

Embodiment 3

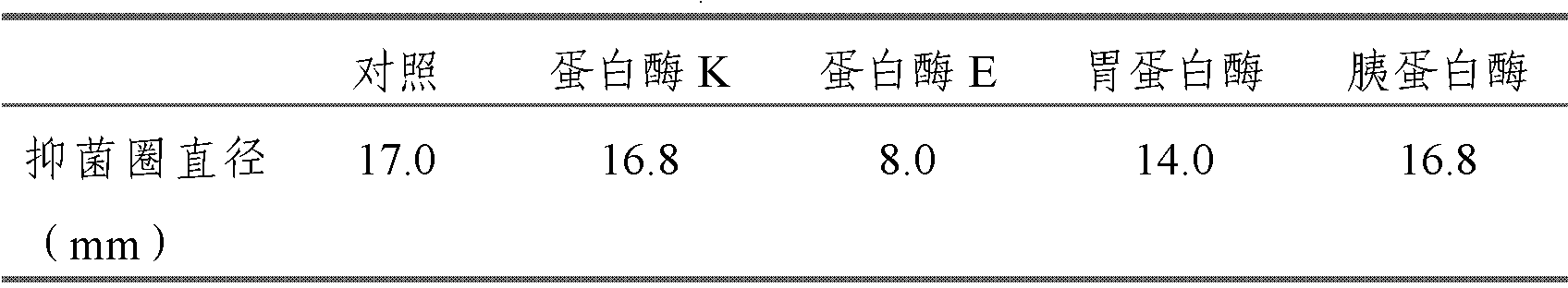

[0049] The determination of antimicrobial peptides adopts the internationally recognized "protease sensitive method", and the fermented liquids obtained in Example 1 and Example 2 are respectively processed as follows: 1. 10,000rpm centrifuged for 15min to remove the bacterium to obtain the supernatant, and then pass through a 0.22 μm filter membrane 2. Adjust the pH of the supernatant to 6.5 to get rid of the effect of organic acids; 3. Take an equal amount of sample solution and mix with 10mg / mL protease (pepsin, protease E, trypsin, protease K) The solution was mixed in 1:1 volume, reacted in a 37°C constant temperature water bath for 2h, and boiled in a 100°C boiling water bath for 5min to kill the enzyme after the reaction; 4. Take the samples before and after protease treatment respectively, and use the agar diffusion method to measure the inhibition zone diameter and compare. The results are shown in Table 1, and the results show that the bacteriostatic substances obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com